Pulse pressure generation device for hydraulic oscillator

A hydraulic oscillator and pulse pressure technology, applied in vibration generating devices, drilling with vibration, wellbore/well components, etc., can solve the problems of increased drill string resistance, prominent gravity effect, high price, etc., and reduce tool pressure consumption. , to meet the effect of practicality and excellent work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

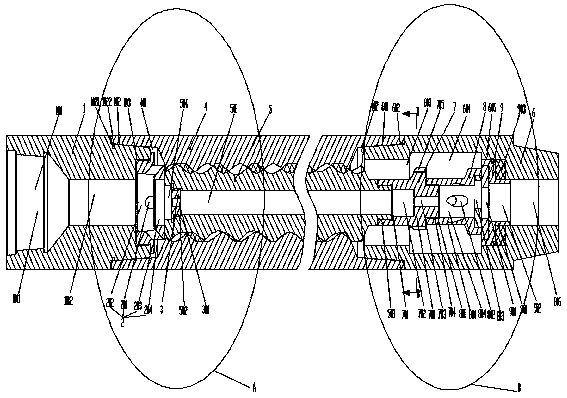

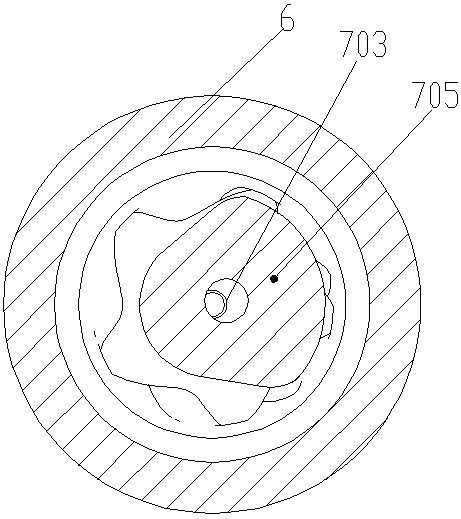

[0027] Such as Figure 1-7The pulse pressure generating device of a hydraulic oscillator shown includes an upper joint 1, a screw stator 4, a screw rotor 5 and a fixed valve joint 6, one side of the upper joint 1 is fixedly connected to one side of the screw stator 4, and the screw rotor 5 is matched. In the screw stator 4, the screw rotor 5 and the screw stator 4 are meshed and matched, and the other side of the screw stator 4 is fixedly connected to the fixed valve joint 6 side. The upper joint 1 is provided with an upper joint passage 101, and the upper joint passes through the flow channel 101. The flow channel 101 is connected to the screw rotor 5 through the upper thruster 2, the rotor nozzle 3 is set at the front of the screw rotor 5, the rear of the screw rotor 5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com