TunneL unfavorabLe geoLogy surrounding rock comprehensive probing treating construction method

A construction method and technology of surrounding rock, applied in tunnels, earthwork drilling, geophysical measurement, etc., can solve the problems of low precision, large error, false abnormality, etc., to ensure the safety and quality, and the effect of great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

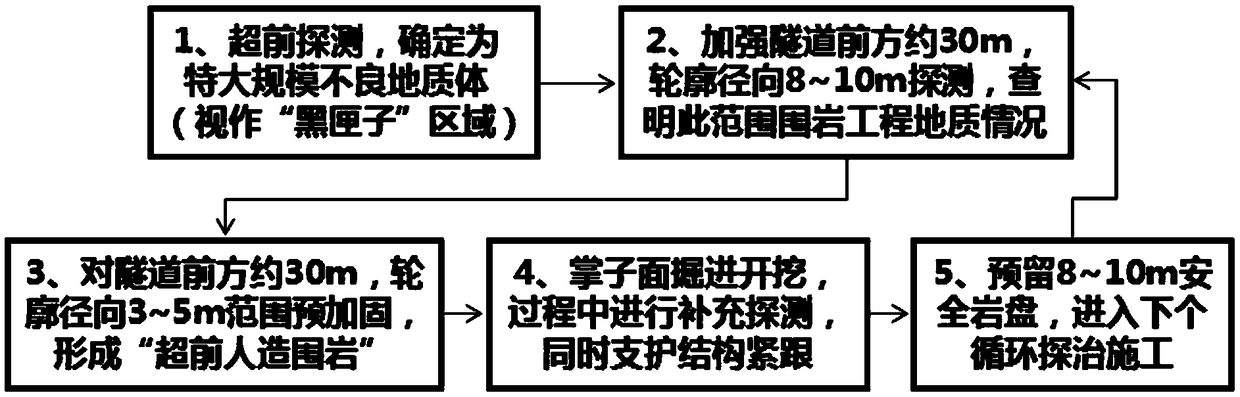

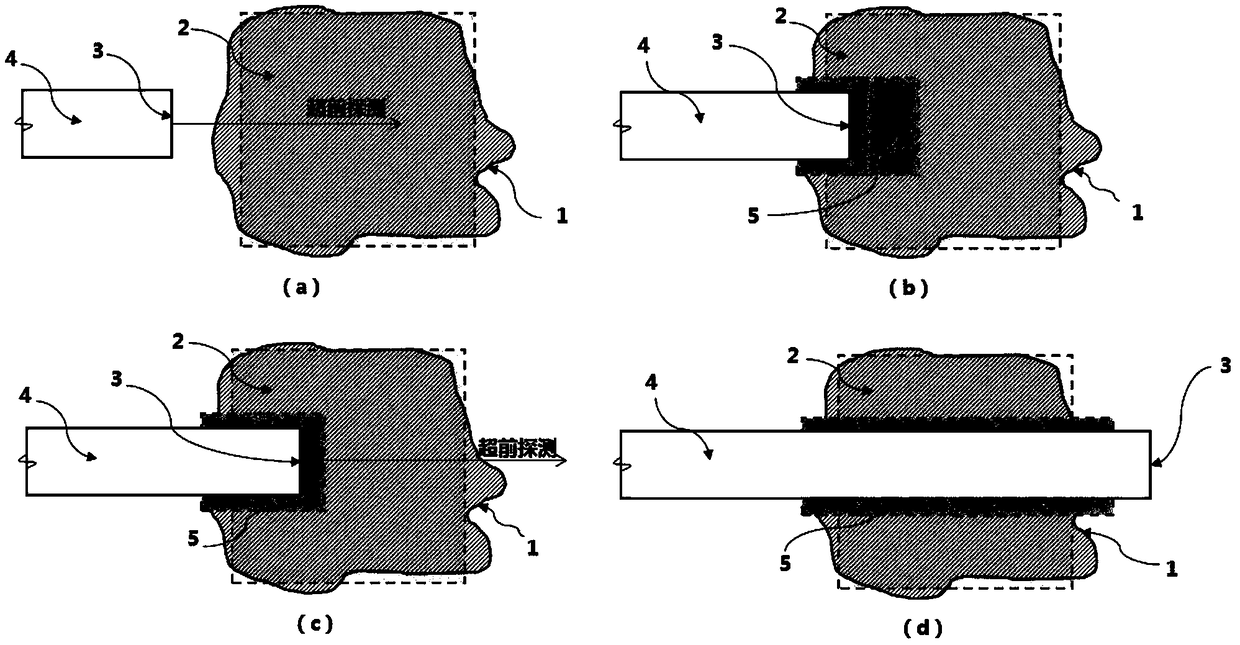

[0025] combine Figure 1-5 As shown, the technical solution adopted in this embodiment is:

[0026] The circular exploration construction method is adopted, including the following steps:

[0027] Step 1: Carry out risk assessment using comprehensive advanced detection technology, and after initially determining a large or extra large unfavorable geological body 1, treat the large or extra large unfavorable geological body 1 as a "black box" area 2; the advanced detection method can use TSP Geophysical prospecting methods such as geological radar and horizontal drilling method are used to predict the surrounding rock of tunnel 3 in advance, and initially determine the scale and nature of unfavorable geological bodies. Think of it as the "black box" area 2.

[0028] Step 2: Under the condition of limited technical level and resources, carry out key detection on the key parts in the "black box" area 2, the key detection range is about 30m in front of the tunnel face, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com