Wheeled crane disassembling and container packing shipping process

A container and tire crane technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as reducing costs, and achieve the effects of reducing costs, facilitating the storage of loose parts, and protecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

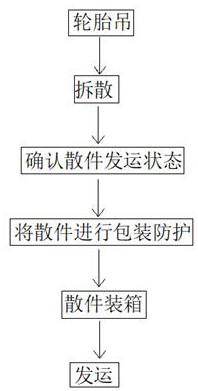

[0023] Such as figure 1 A tire crane dismantling bulk container shipping process shown, the steps include:

[0024] S1: Dismantling of the tire crane:

[0025] Disassemble the tire crane into several parts, including main girder, outrigger, saddle beam, trolley assembly, power room, electrical room, crane cable reel, driver's cab, cart, wooden box and ladder platform .

[0026] S2: Confirm the delivery status of the spare parts:

[0027] The delivery of loose parts involves joint transportation, which often needs to be transported by sea first, and then transported by road or rail. The transportation capacity of many importing countries is weak. It is necessary to survey along the way in advance to understand the clear height of bridge openings and lines, the width of the road, the turning radius of the road and the boarding conditions of obstacles along the way.

[0028] First confirm the transportation size limit of the parts according to the transportation road conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com