Shear wall side forming staircase steel mold and mounting method

A shear wall and stair technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as rework, slag inclusion in stair construction joints, improper thickness of protective layer, etc. Safety and quality, lower construction cost, good fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

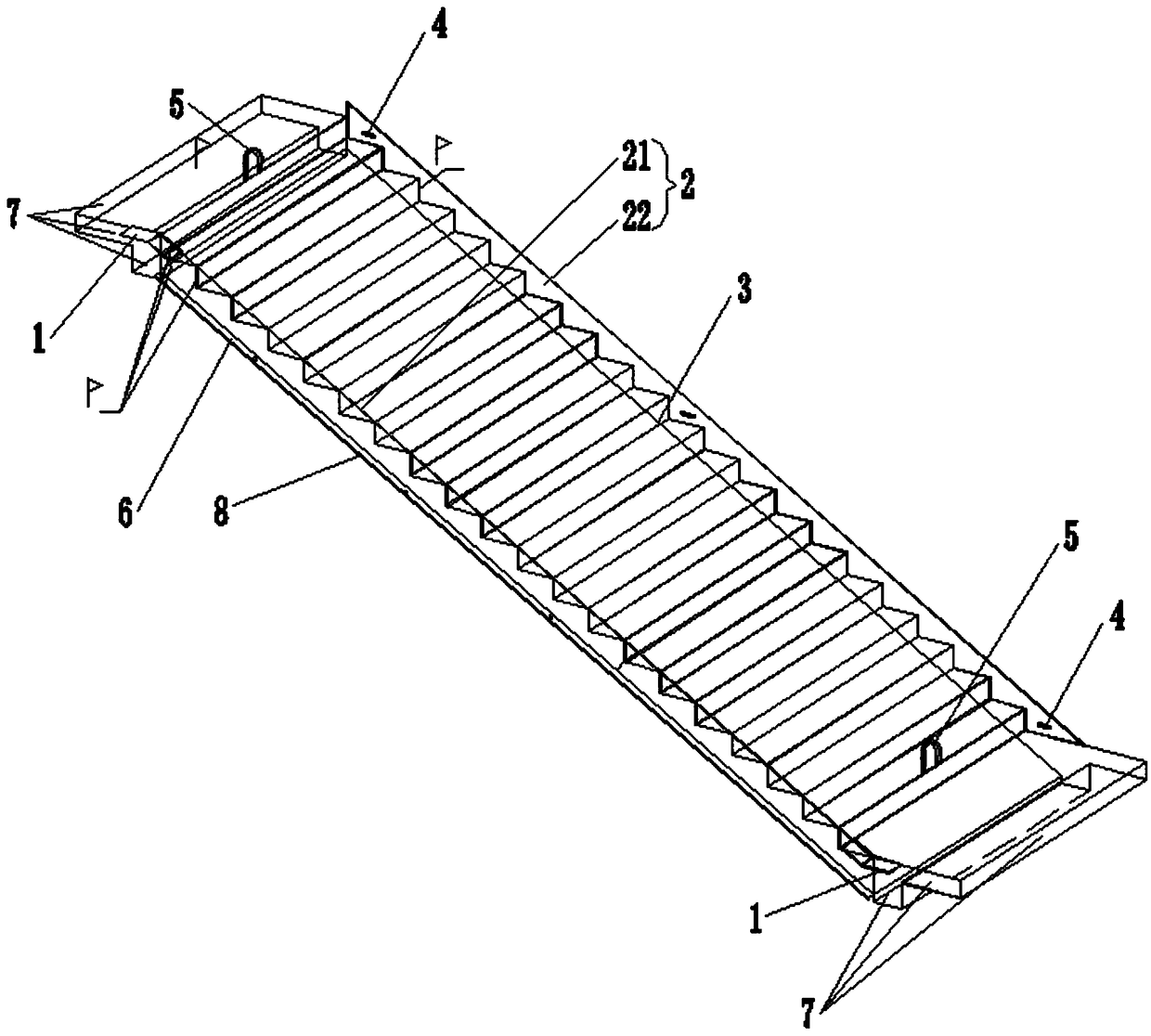

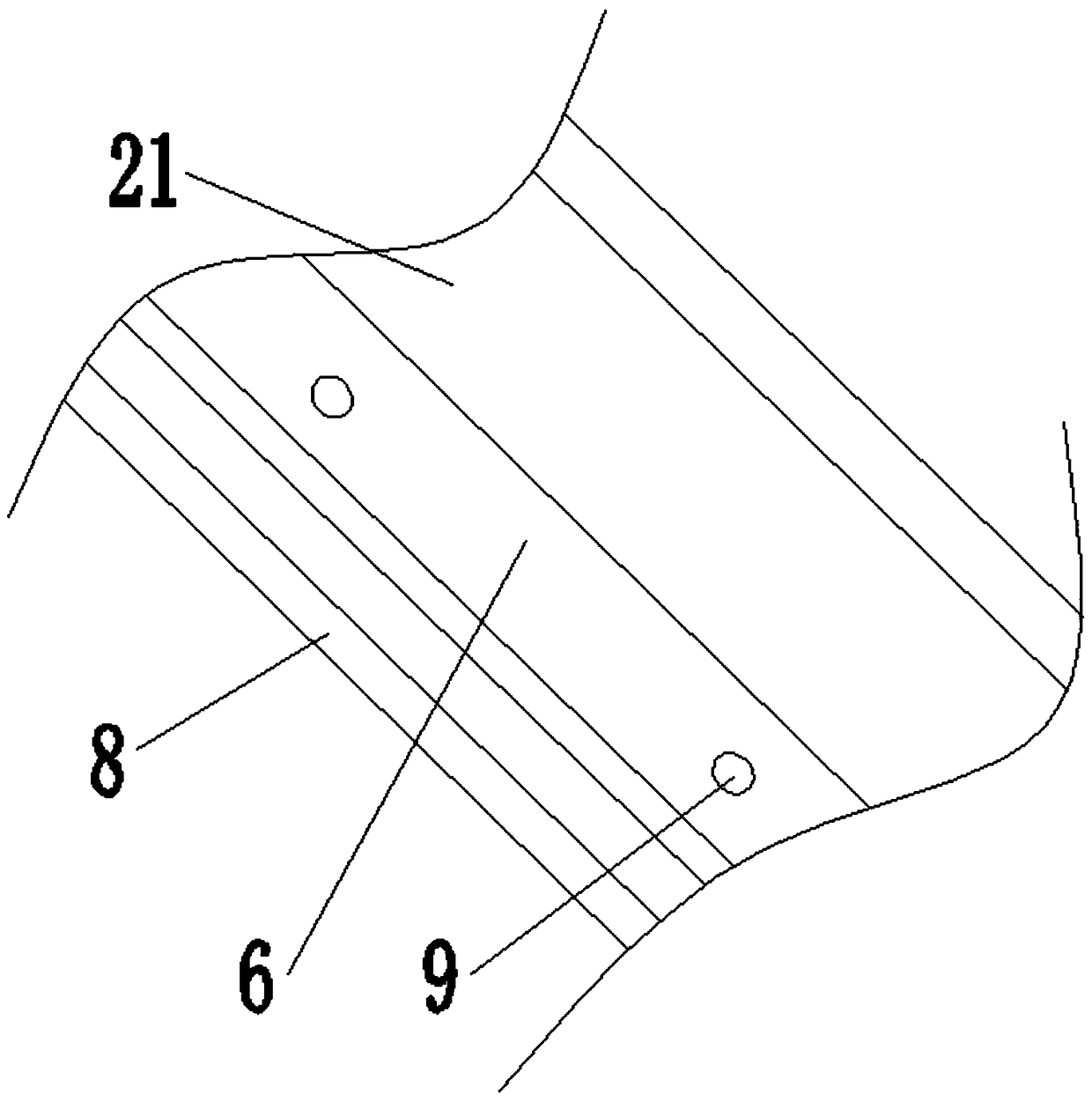

[0040] Such as Figure 1-2 Shown: .

[0041] A steel formwork for a shaped staircase on the side of a shear wall, comprising a shear wall, a concrete layer 7, and a support formwork 8 located between the concrete layers 7, the shear wall is reserved for lock-foot screws, and also includes a Stylized staircase steel formwork,

[0042] Stereotyped staircase steel mold:

[0043] Including a steel grating 1, which includes a top steel grating and a bottom steel grating,

[0044] Including a side panel 2, which includes a far wall side panel 21 and a near wall side panel 22,

[0045] including panel 3,

[0046] The upper opening of the side panel 21 of the far wall is flush with the upper opening of the panel 3, and the lower opening of the side panel 21 of the far wall closely fits with the reserved support template 8;

[0047] The lower opening of the side panel 22 near the wall is flush with the lower opening of the panel 3 , and the upper part of the side panel 22 close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com