Permanent leakage-free maintenance system built in underground engineering

An underground engineering, permanent technology, applied in infrastructure engineering, construction, protection devices, etc., can solve problems such as difficult maintenance, no warranty requirements for waterproof quality, and no quality maintenance system for underground engineering, to ensure quality, safety, and convenience. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

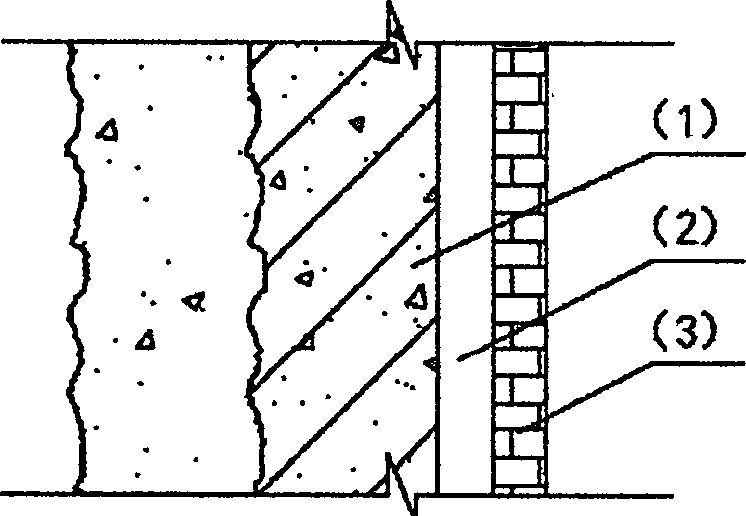

[0015] exist figure 1 Among them, the structural exterior wall facing the interior is a bare structural wall surface (1), and the partition wall (3) is a hollow structural layer of the wall body built with a hollow layer (2).

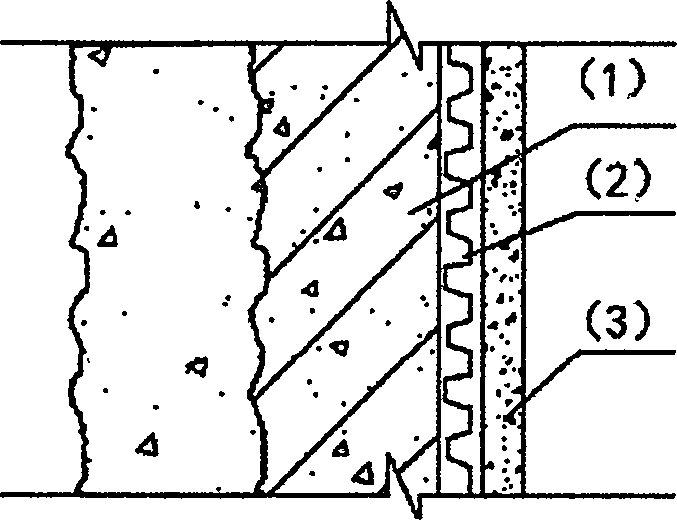

[0016] figure 2 , the exterior wall of the structure faces the interior is a bare structural wall (1), fix the plastic plate with fulcrum on the wall, form a hollow layer 2 in the middle, and then paint with cement mortar or fix the prefabricated cement pressure plate to form a hollow structural layer (3).

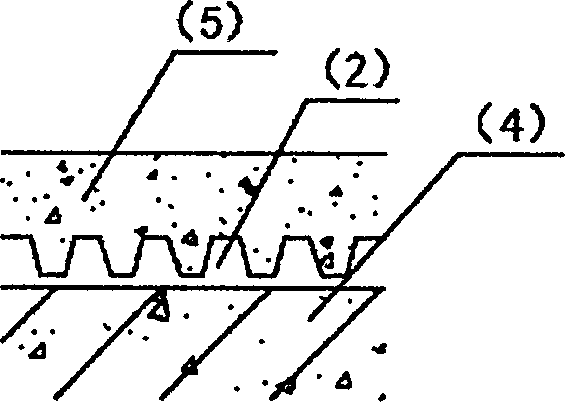

[0017] image 3 , on the exposed structural ground (4) is covered with plastic plates with empty cup fulcrums and then poured concrete to become the floor hollow structure layer (5), and the center of the fulcrum is the hollow layer (2).

[0018] Figure 4 , install the openable skirting board (6) on the concrete floor at the bottom of the wall, which is the opening cover of the hollow layer of the wall, which can be closed with silica gel. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com