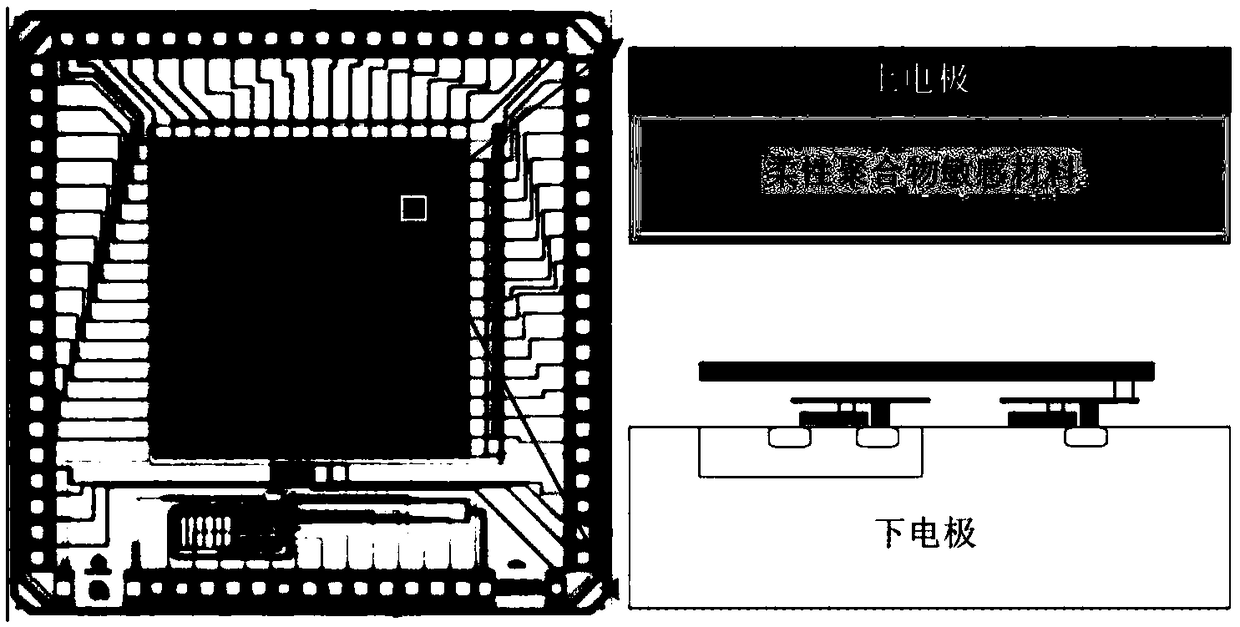

Low piezoelectric and temperature interference flexible pyroelectric infrared thermal imager pixel array

A technology of pyroelectric infrared and pixel array, which is applied in the field of infrared thermal imaging cameras, can solve the problems of reduced imaging quality of infrared thermal imaging cameras, and achieve the elimination of interference from external environmental vibration and temperature fluctuations, good symmetry and stability, The effect of easy elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

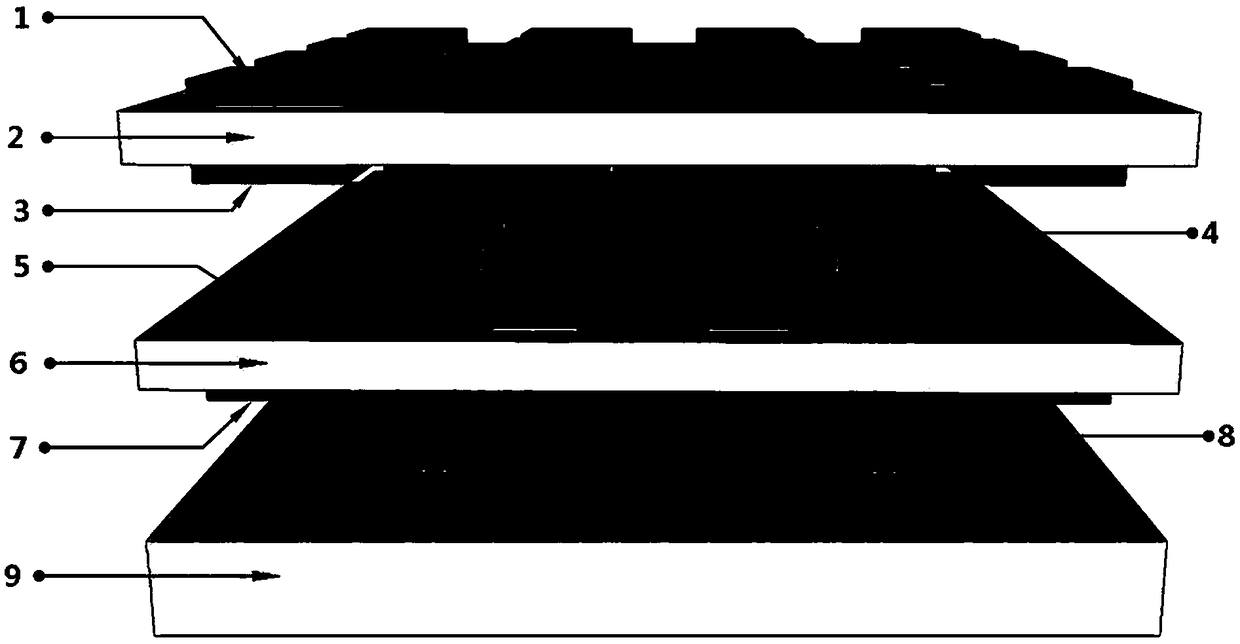

[0070] The method for manufacturing the pixel array of the flexible pyroelectric infrared camera with low voltage and temperature interference includes the following steps:

[0071] Step 1: Dissolve the flexible pyroelectric polymer completely into a solution, and then evenly cover the solution on the flat substrate, and then bake it in a constant temperature box until the solvent is completely volatilized, and the flexible pyroelectric polymer forms a sensitive film, and then Peel off the sensitive film to obtain a 20mm×20mm flexible pyroelectric polymer film;

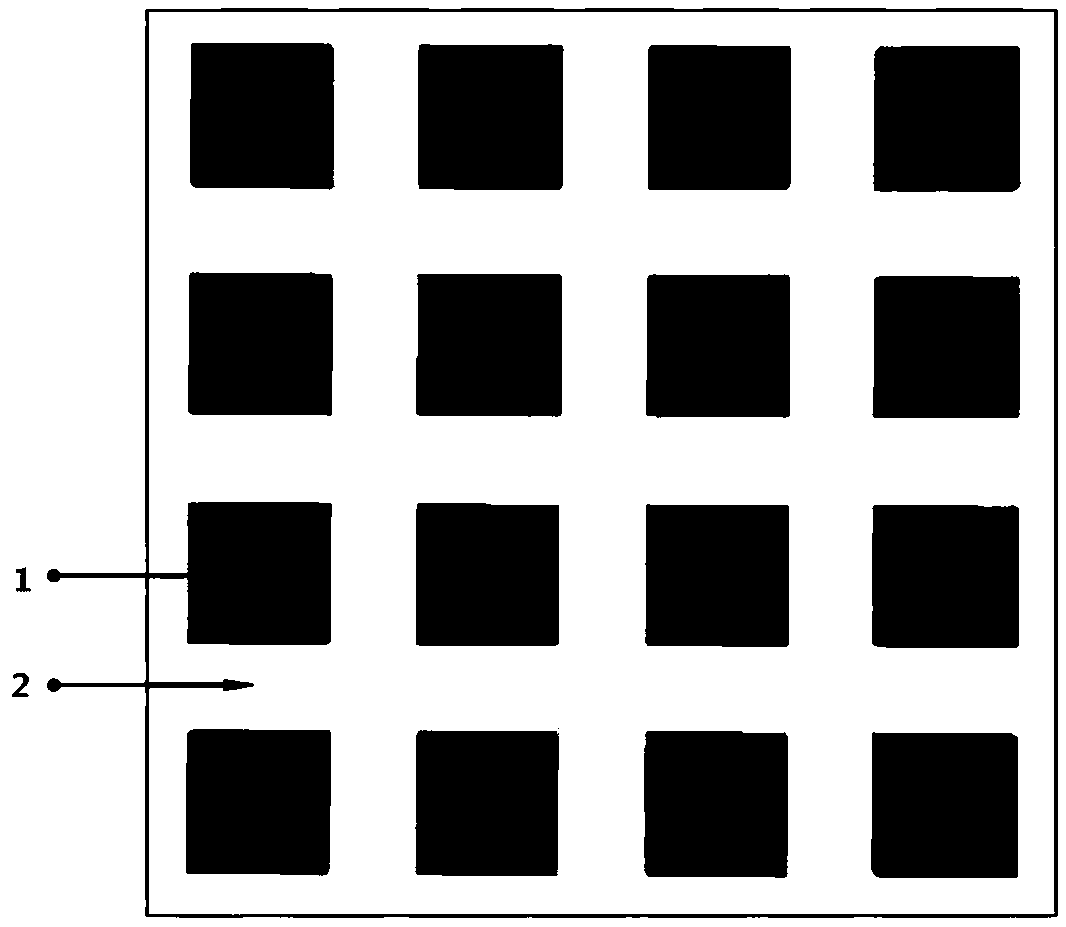

[0072] Step 2: Prepare the same thickness on the surface of the obtained flexible pyroelectric polymer film with the internal polarization direction of 20mm×20mm by evaporation and sputtering, such as image 3 As shown in the metal pixel electrode array in a 4×4 matrix, an identical 4×4 matrix metal pixel electrode array is set on the other surface of the film;

[0073] Step 3: Use silicon materials to prepare adiaba...

Embodiment 2

[0078] The method for manufacturing the pixel array of the flexible pyroelectric infrared camera with low voltage and temperature interference includes the following steps:

[0079] Step 1: Dissolve the flexible pyroelectric polymer completely into a solution, and then evenly cover the solution on the flat substrate, and then bake it in a constant temperature box until the solvent is completely volatilized, and the flexible pyroelectric polymer forms a sensitive film, and then Peel off the sensitive film to obtain a 20mm×20mm flexible pyroelectric polymer film;

[0080] Step 2: Prepare the same thickness on the surface of the obtained flexible pyroelectric polymer film with the internal polarization direction of 20mm×20mm by evaporation and sputtering, such as image 3 In the shown metal pixel electrode array in a 4×4 matrix, a planar electrode is arranged on the other surface of the film;

[0081] Step 3: Prepare a cross-sectional area of 1mm with silica material 2 , a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com