Modeling method of using membrane humidifier to realize fuel-cell intake-air humidification

A membrane humidifier and fuel cell technology, applied in fuel cells, electrical components, instruments, etc., can solve the problems of transient response, difficulty in humidification efficiency stack influence, destruction of stack life, and reduction of true accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The modeling process of the present invention will be further described through specific examples below. It should be noted that this calculation example is descriptive rather than restrictive, and does not limit the scope of protection of the present invention.

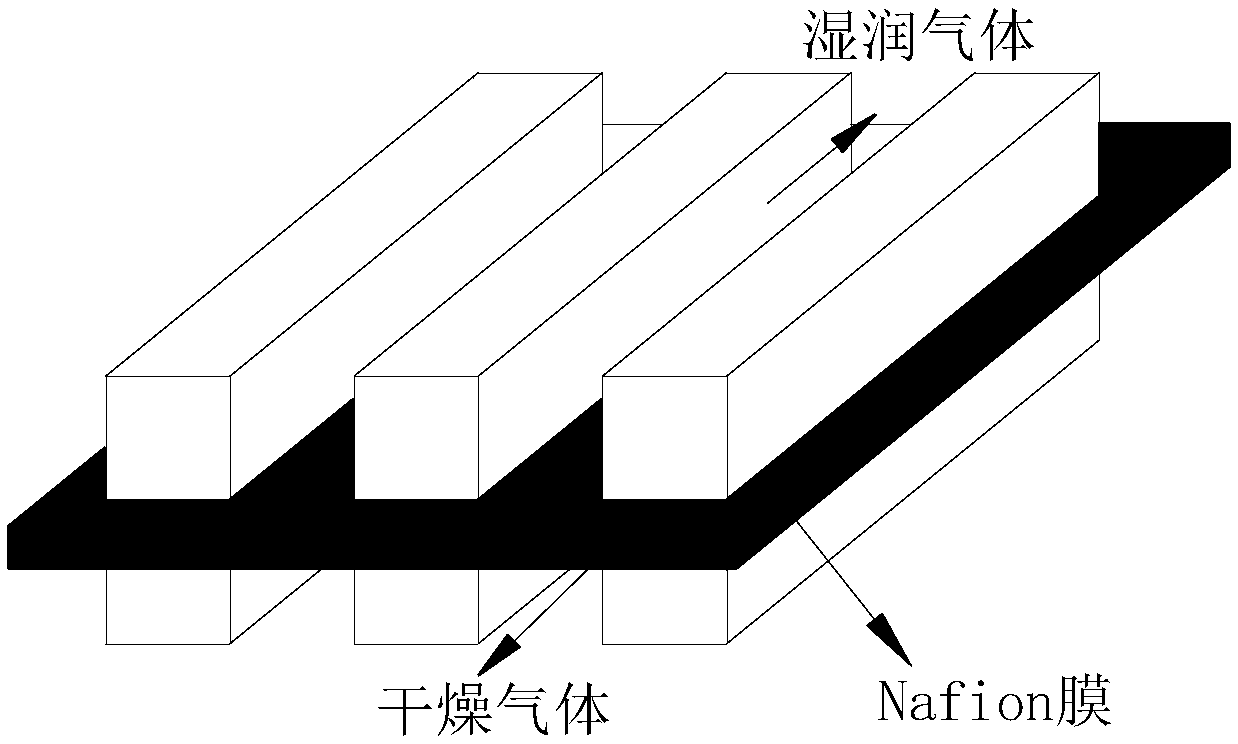

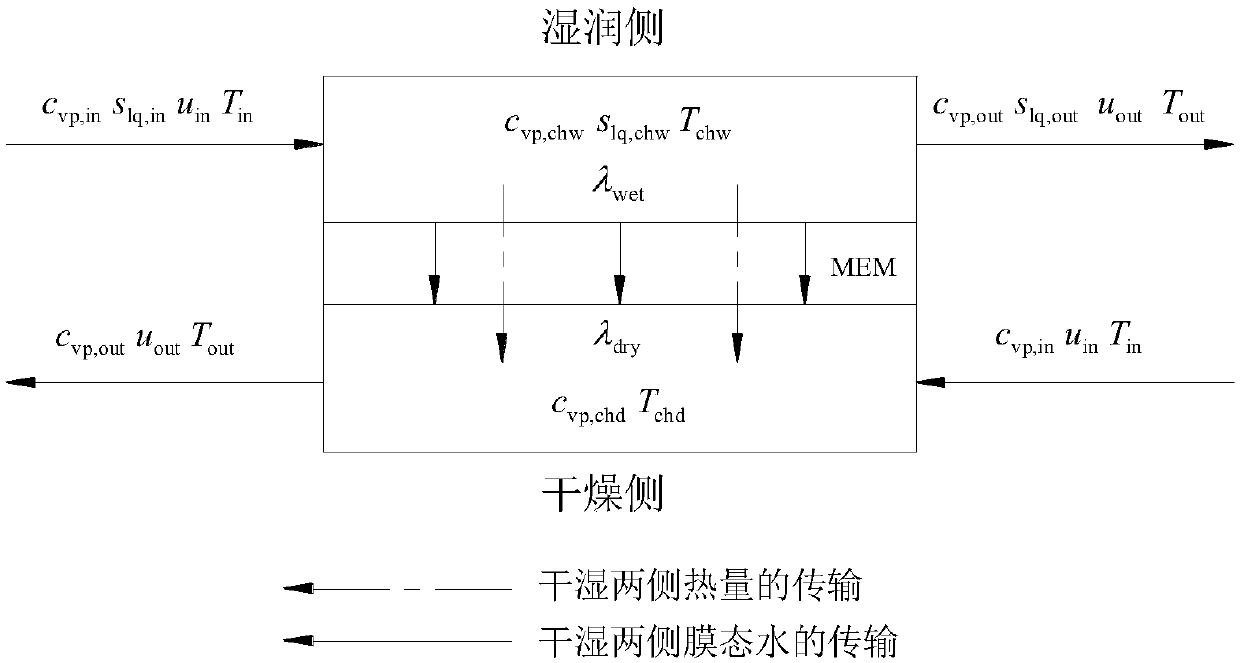

[0065] The physical structure of the flat membrane humidifier is as follows: figure 1 As shown, the main structure includes wet and dry side channels and proton exchange membrane. Humidification process such as figure 2 As shown, it can be roughly divided into the following stages: first, the water vapor in the wet side channel is absorbed by the membrane, then the water molecules diffuse to the dry side under the action of the concentration difference between the dry side and the wet side, and finally the water in the dry side membrane and The water vapor in the flow channel establishes an equilibrium state, and then infiltrates the air. The above water transfer process is accompanied by heat transfer.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com