Power semiconductor module for a motor vehicle and motor vehicle

A technology for power semiconductors and motor vehicles, applied in semiconductor devices, semiconductor/solid-state device parts, electric vehicles, etc., can solve problems such as hindering heat transfer, and achieve low cost and effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

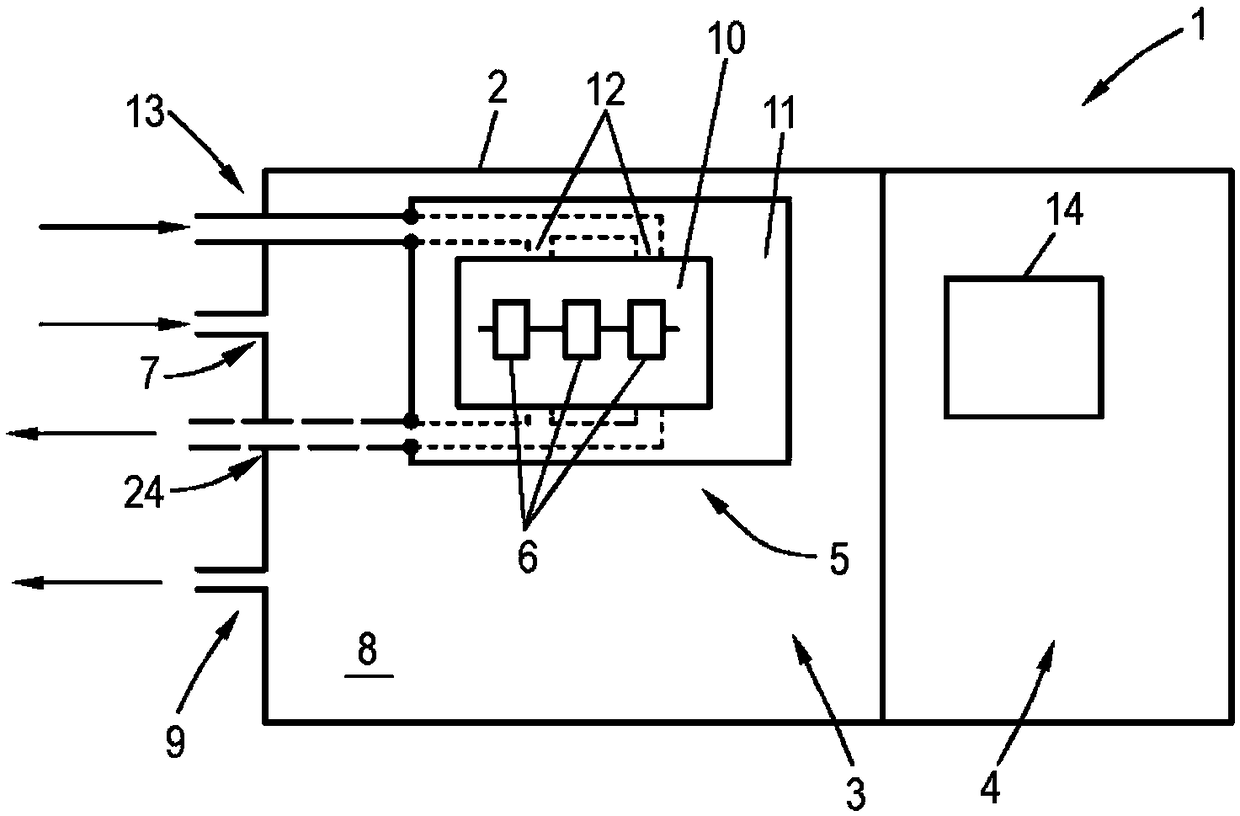

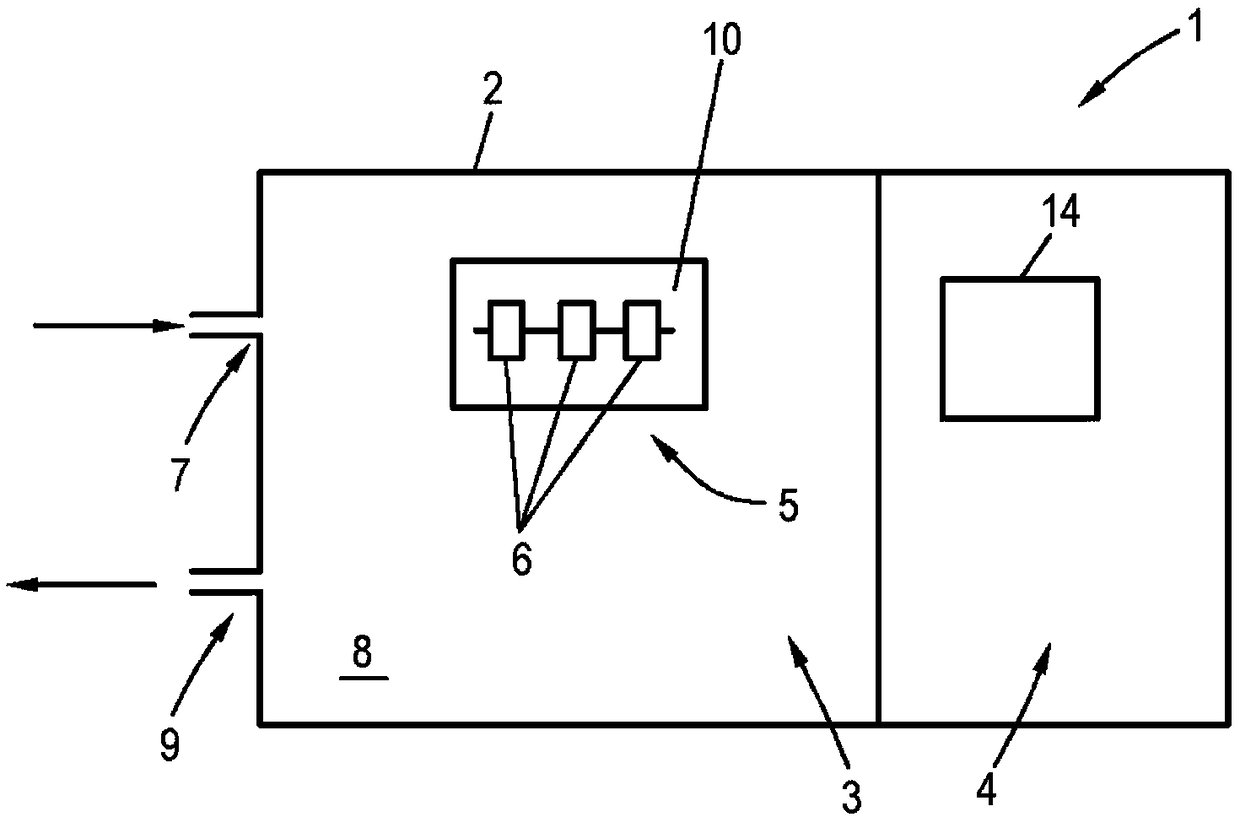

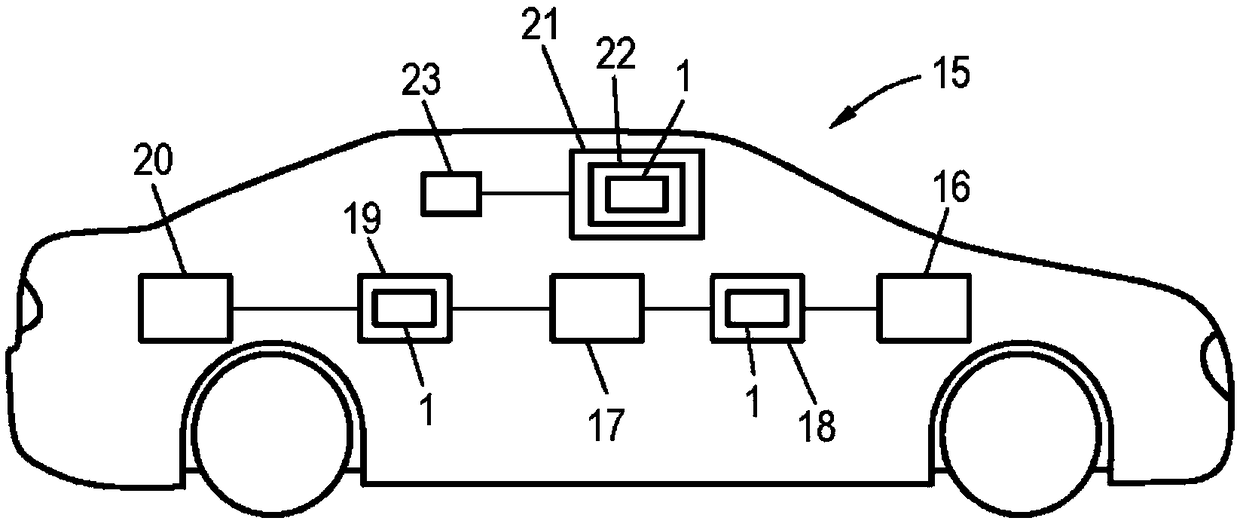

[0022] figure 1 A schematic diagram of a first exemplary embodiment of a power semiconductor module 1 is shown, comprising a housing 2 with a first housing part 3 and a second housing part 4 .

[0023] A plurality of power semiconductor chips 6 arranged on a carrier element 5 without a housing, for example IGBTs or power-chips designed as bare chips with associated freewheeling diodes, are accommodated in the first housing part 3 . MOSFETs. The power semiconductor chips 6 are shown purely schematically and are connected as a bridge circuit, for example a half bridge or a B6 bridge. The first housing part 3 also has a coolant supply line 7 , by means of which an electrically insulating coolant 8 is poured into the liquid-tightly closed interior of the first housing part 3 . The cooling fluid 8 thus flows directly around the power semiconductor chip 6 without housing and thus dissipates the heat generated by the power semiconductor chip during operation. To discharge the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com