One-dimensional nano-wire hydroxyl cerium carbonate/graphene composite material and preparation method thereof

A technology of linear hydroxycarbonic acid and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor electrical conductivity, limited application, and commercial application limitations, and achieve improved electrical conductivity, improved stability, and enhanced cracking effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention discloses a preparation method of a one-dimensional nanowire hydroxy cerium carbonate / graphene composite material, comprising the following steps:

[0030] 1) Mix graphene oxide solution and ethylene glycol solution, the volume ratio of graphene oxide solution and ethylene glycol solution is 1:(1~3), the mass concentration of graphene oxide solution is 1~10mg / ml; Gained After the solution is ultrasonically treated, a uniform mixed solution is obtained, the ultrasonic time is 20-40min, and the ultrasonic power is 150W.

[0031] 2) Transfer the mixed solution obtained in step 1) to a magnetic stirrer, and add cerium nitrate hexahydrate during the stirring process; the ratio of added cerium nitrate hexahydrate to graphene oxide solution is (2~12) mg : 5ml, stir magnetically to obtain a suspension mixture evenly;

[0032] 3) Add NaCl and urea to the suspension mixture obtained in step 2), the mass ratio of the added NaCl to cerium nitrate hexahydrate is 10: (...

Embodiment 1

[0037] Mix 25ml of graphene oxide solution (3mg / mL) with 25ml of ethylene glycol solution and sonicate for 30min, then transfer to a magnetic stirrer, add 30mg of cerium nitrate hexahydrate, magnetically stir to form a uniform suspension mixture; add 100mgNaCl, 100mg urea, use 1mol / mLNaOH solution to control the pH value of the system to 12, continue to stir for a period of time, put the mixed solution into a stainless steel autoclave lined with 100ml polytetrafluoroethylene, seal it and put it in a constant temperature oven for 200 ℃ water heating for 180min, after the reaction, take out the reactor, let it cool down to room temperature naturally, centrifuge to collect the precipitate, and wash it repeatedly with ethanol / deionized water (1:2) mixture for 6 times, then put the precipitate in a vacuum oven for 60 °C and dried for 12 hours to obtain nanowire cerium hydroxycarbonate / graphene composite material.

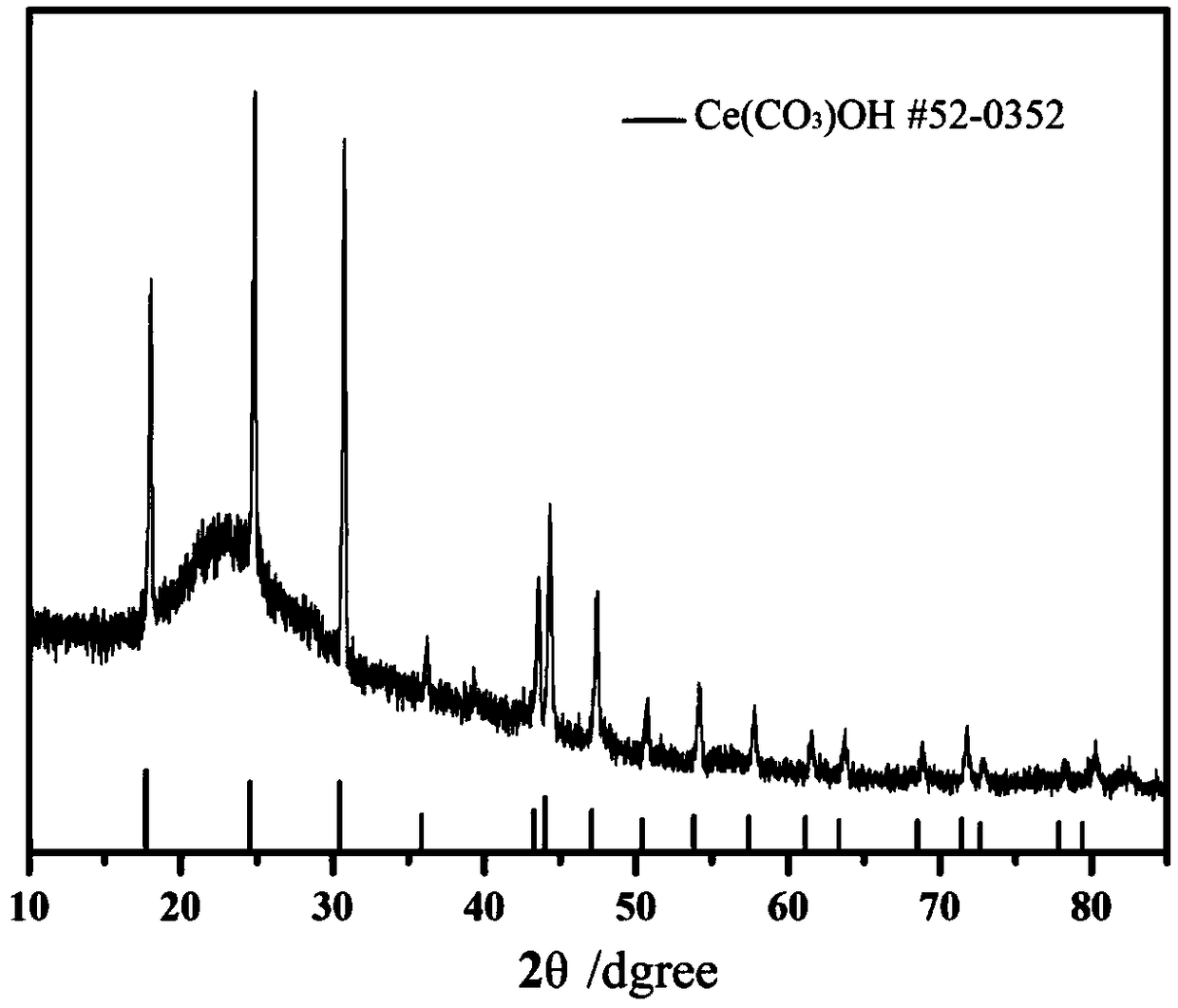

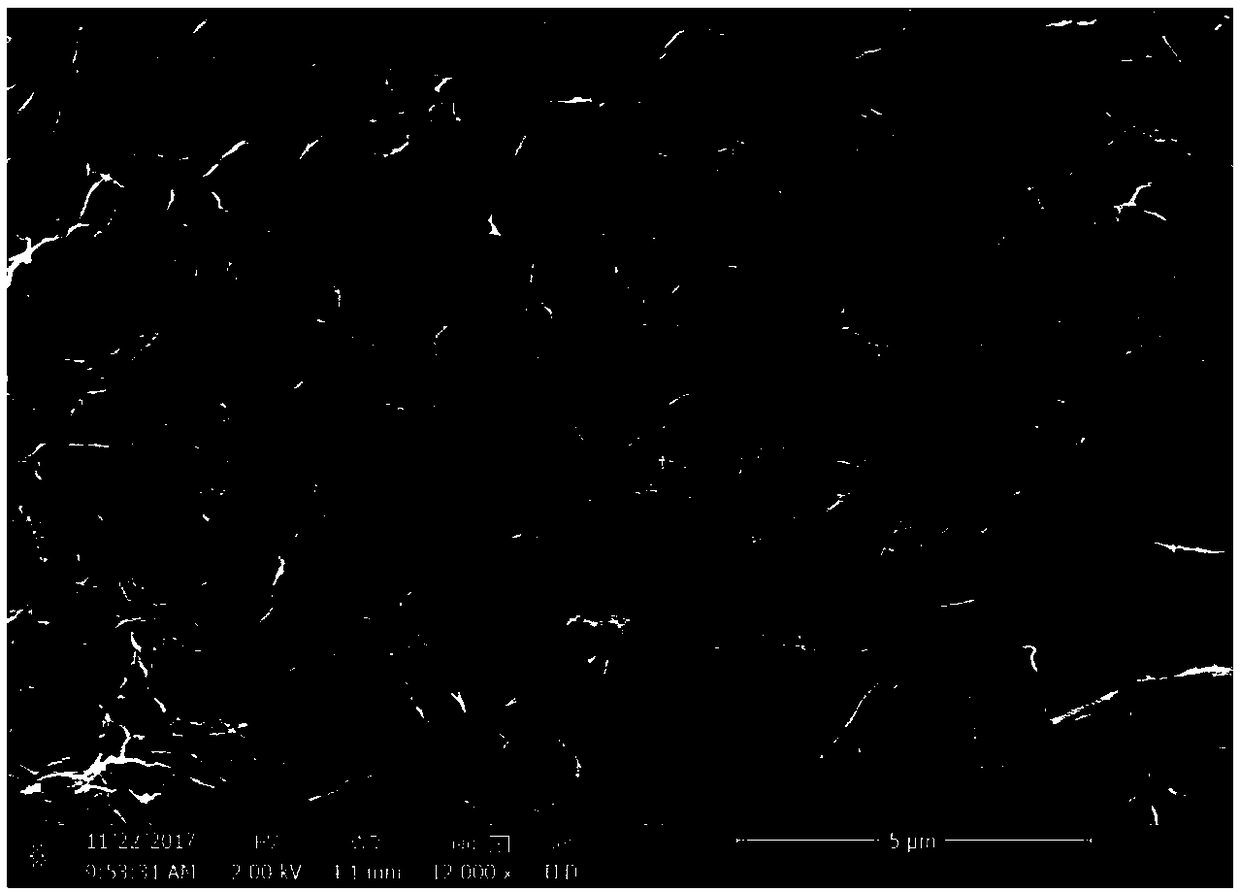

[0038] Carry out XRD, SEM analysis to embodiment 1 gained nanowire ...

Embodiment 2

[0043] Mix 25ml of graphene oxide solution (3mg / mL) with 25ml of ethylene glycol solution and sonicate for 30min, then transfer to a magnetic stirrer, add 60mg of cerium nitrate hexahydrate, magnetically stir to form a uniform suspension mixture, add 100mgNaCl, 150mg urea, then use 1mol / mL NaOH solution to control the pH value of the system to 13, after continuing to stir for a period of time, put the mixed solution into a stainless steel autoclave lined with 100ml polytetrafluoroethylene, seal it and put it in a constant temperature Heat water at 200°C in an oven for 180 minutes. After the reaction, take out the reaction kettle, let it cool down to room temperature naturally, collect the precipitate by centrifugation, and wash it repeatedly with ethanol / deionized water (1:2) mixture for 6 times, and then put the precipitate in a vacuum Dry in an oven at 60° C. for 12 hours to obtain a nanowire cerium hydroxycarbonate / graphene composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com