Overhead transmission line grounding line repair device and repair method

A technology of overhead transmission lines and ground wires, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve problems such as the need for manual wiring, and achieve the effects of improving maintenance capabilities, operating safety, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

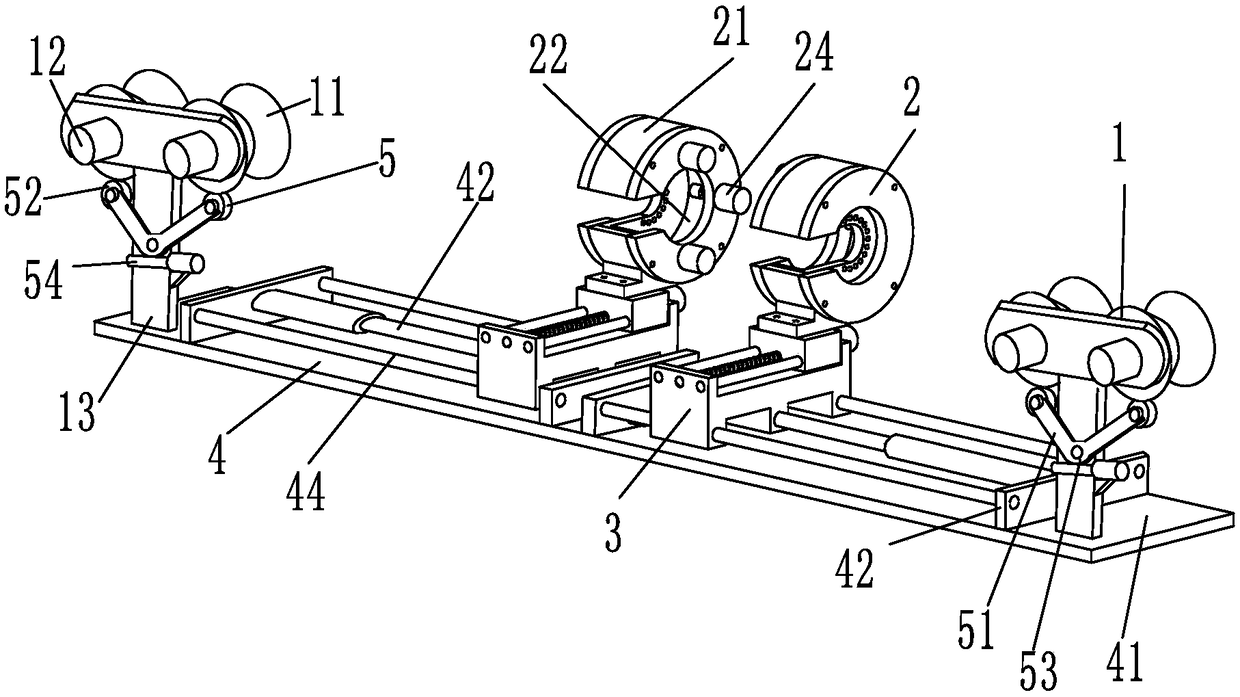

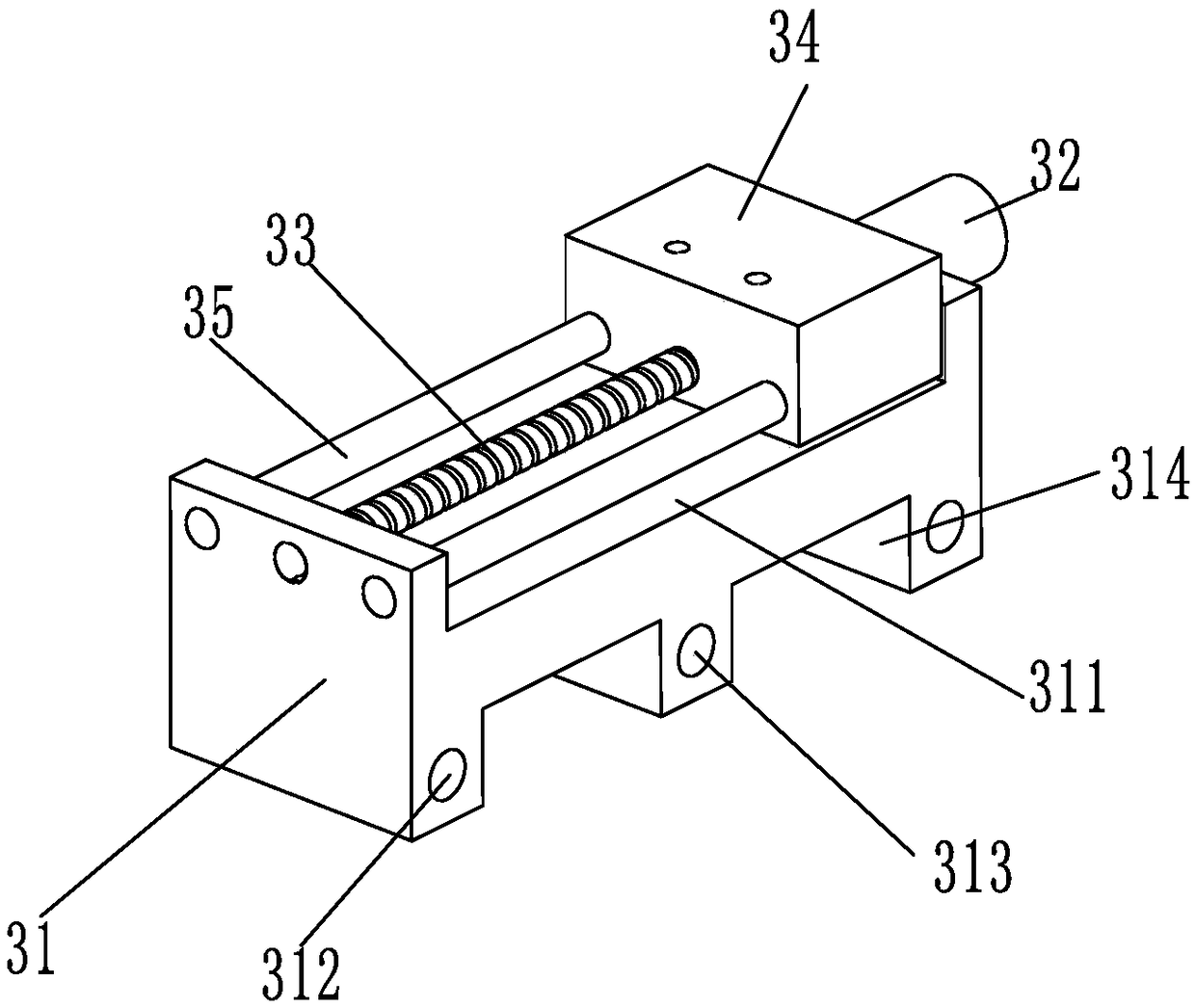

[0035] figure 1 , figure 2 and image 3 Among them, a device for repairing the ground wire of an overhead power transmission line includes a winding assembly 2, a moving assembly 1 and an obstacle avoidance assembly 3: the winding assembly 2 includes two winding disks 22 that can spirally move in opposite directions, and the outside of the two winding disks 22 A winding base 21 is respectively provided, and the winding disc 22 can rotate relative to the winding base 21, and the two winding bases 21 can move relative to each other along the direction parallel to the ground wire.

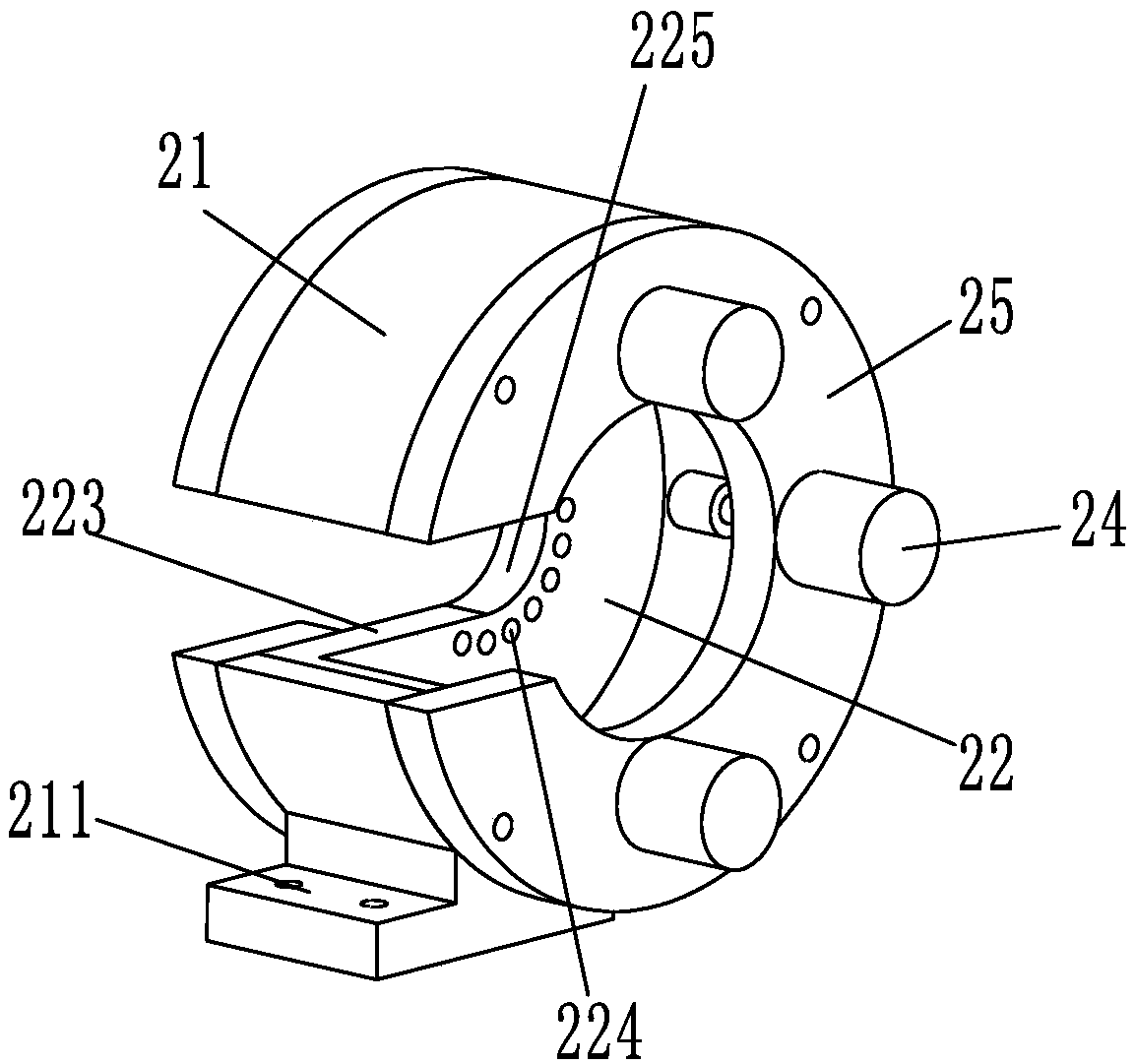

[0036] The winding disc 22 is provided with an opening 223 that can be inserted into the ground wire and a winding hole 225 for matching the ground wire. The winding base 21 is also provided with an opening 223 for matching the ground wire. The height is equal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com