Push-twist type microswitch oiler

A micro switch, push-twist technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of troublesome operation process, inability to cycle feeding, high cost, etc., and achieve simple operation process, uniform feeding and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

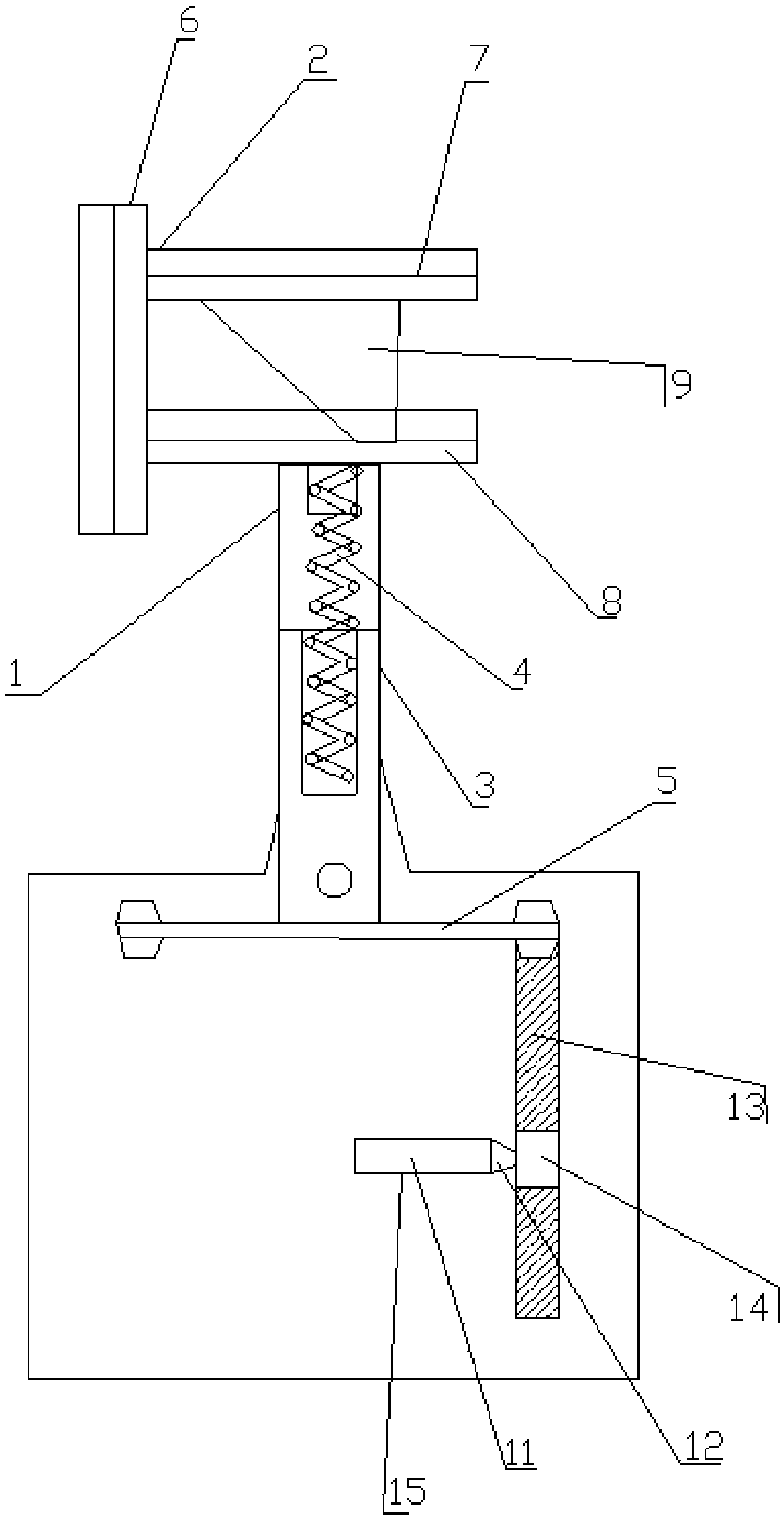

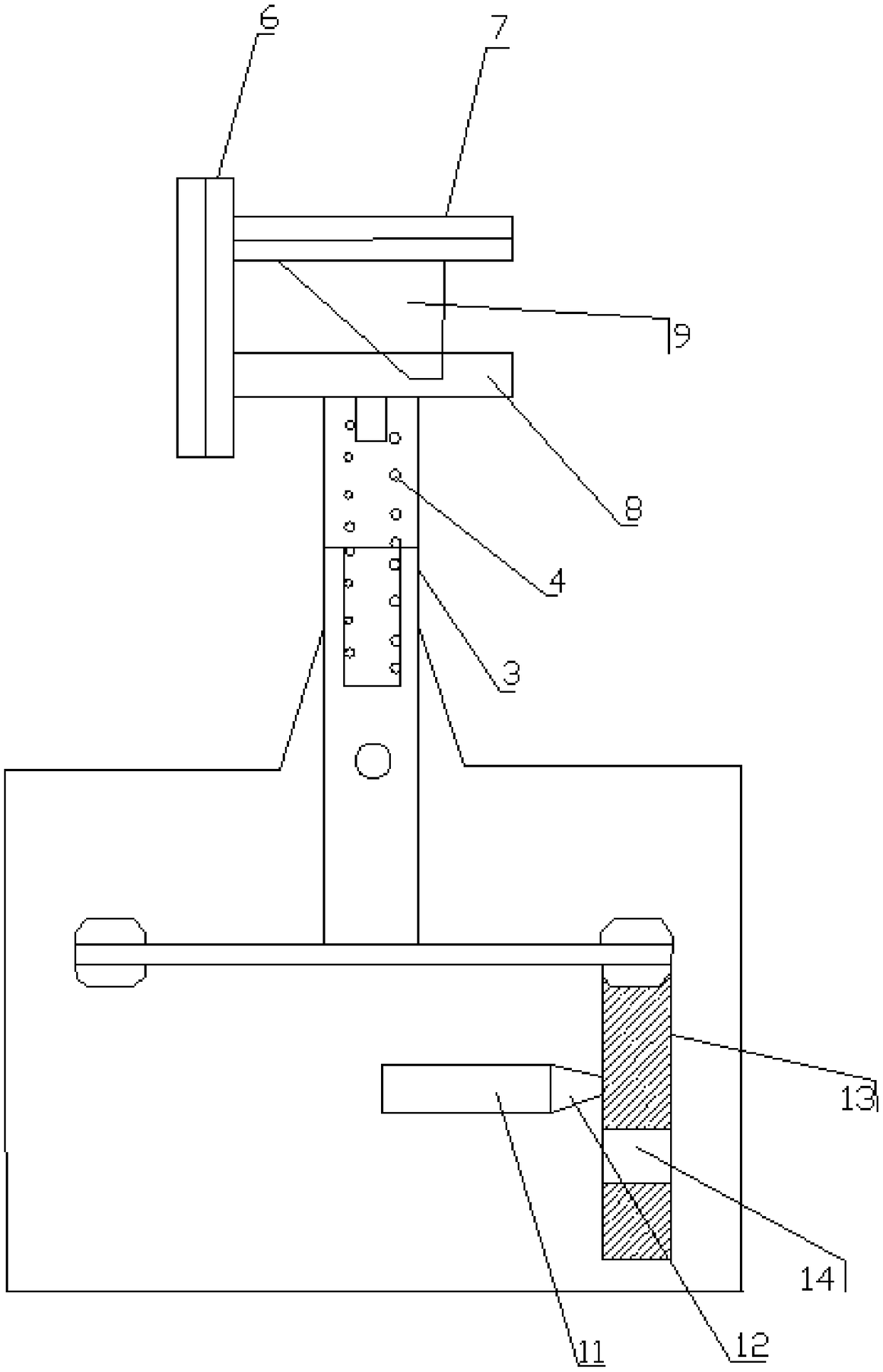

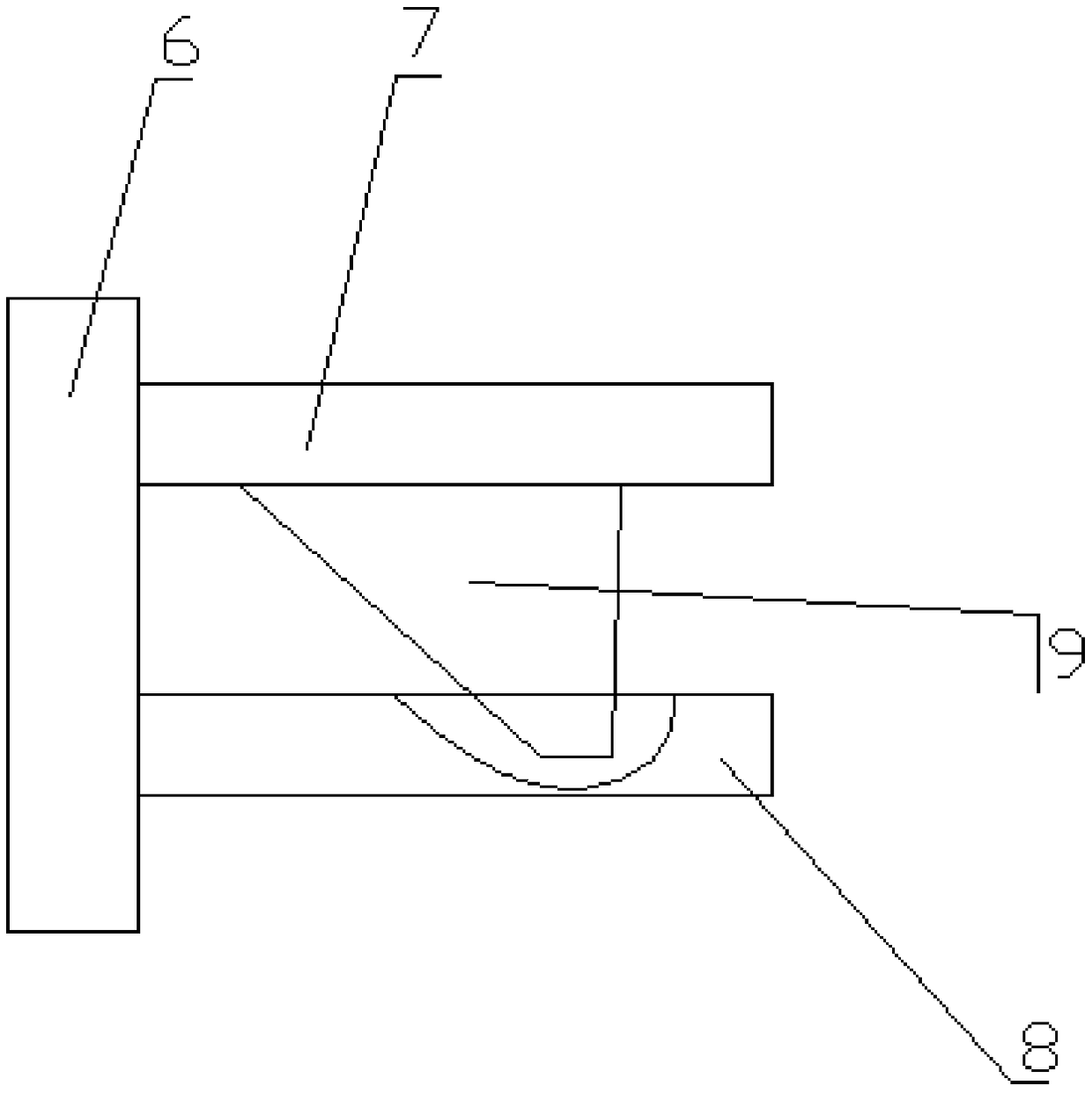

[0039]When the user uses the present invention, the first gear set 6 drives the second gear 7 and the third gear 8 to run, because the number of teeth of the second gear 7 and the third gear 8 differs by one, and the second gear 7 and the third gear 8 are provided with a The gear connection structure 9, the gear connection structure 9 squeezes or presses the third gear 8, the tooth connection structure 9 includes an arc-shaped wedge, and the third gear 8 is provided with a tooth groove matched with a wedge or a gear shifting slope, The rotation speed is different, the wedge of the gear connection structure 9 presses the tooth groove on the third gear 8 from slow to accelerated, the third gear 8 pushes the push-twist assembly 3 to move, the third gear 8 connects the push-twist assembly 3, the third gear 8 The gear 8 squeezes or presses the push-twist assembly 3, the push-twist assembly 3 moves, and the dynamic contact block 5 moves up and down under the push of the push-twist as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com