Ultrasonic testing method for subway diaphragm wall construction quality

A technology for underground diaphragm walls and construction quality, which is applied in foundation structure engineering, foundation structure testing, construction, etc., to achieve the effect of ensuring accuracy and feasibility and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the key points of each operation of this construction method will be described in detail.

[0021] Layout of acoustic tube:

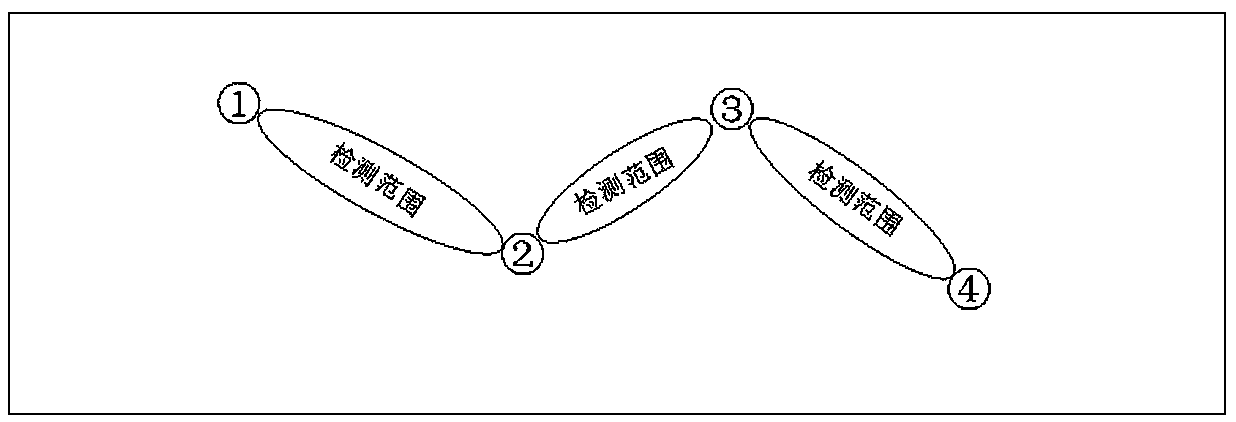

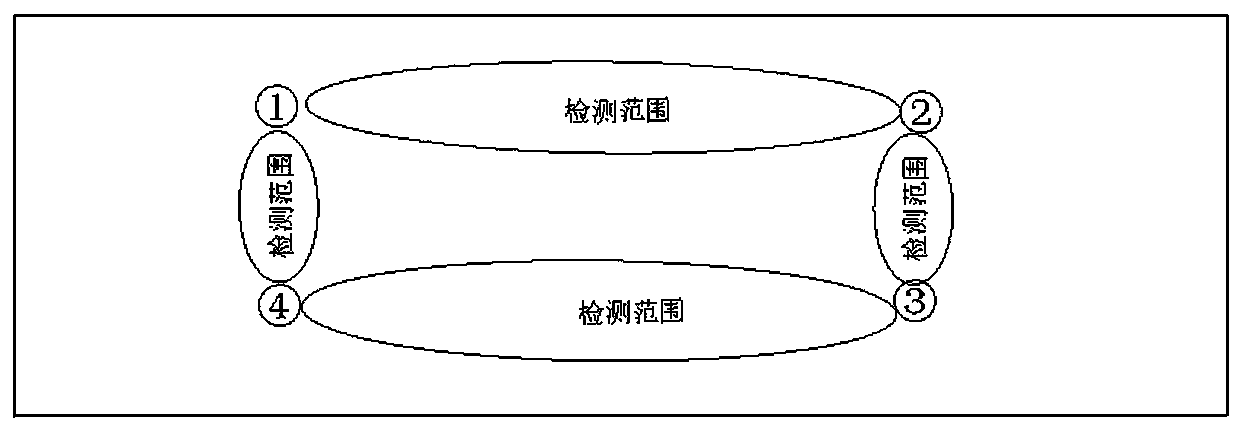

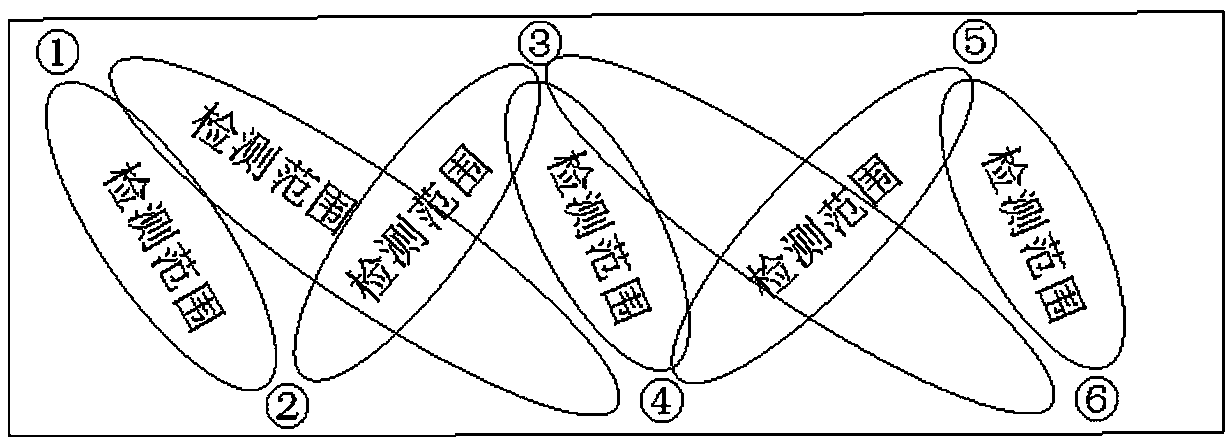

[0022] The length of a piece of subway ground connection wall is generally 6m. At present, 4 acoustic tubes are generally arranged in the ultrasonic inspection of the ground connection wall on the construction site in a "Z" or rectangular arrangement. The "Z" shape layout is as follows: figure 1 As shown, the rectangular layout is as follows figure 2 shown. By analyzing the layout of the above-mentioned acoustic tubes, it can be found that the current ultrasonic ground wall integrity detection of the subway has the biggest disadvantage: since the length of a ground wall is generally 6m, the ultrasonic detection distance generally does not exceed 2.5m , arrange the acoustic tubes in the above way, because the diagonal distance of the acoustic tube plane is too large, resulting in the inability to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com