Method for adopting linear fireflood for producing tail gas for burying and utilization

A fire-flooding tail gas and fire-flooding technology, which is applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of high air consumption, pollution, and large investment in tail gas treatment. The effect of improving oil recovery and improving utilization rate of gas injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

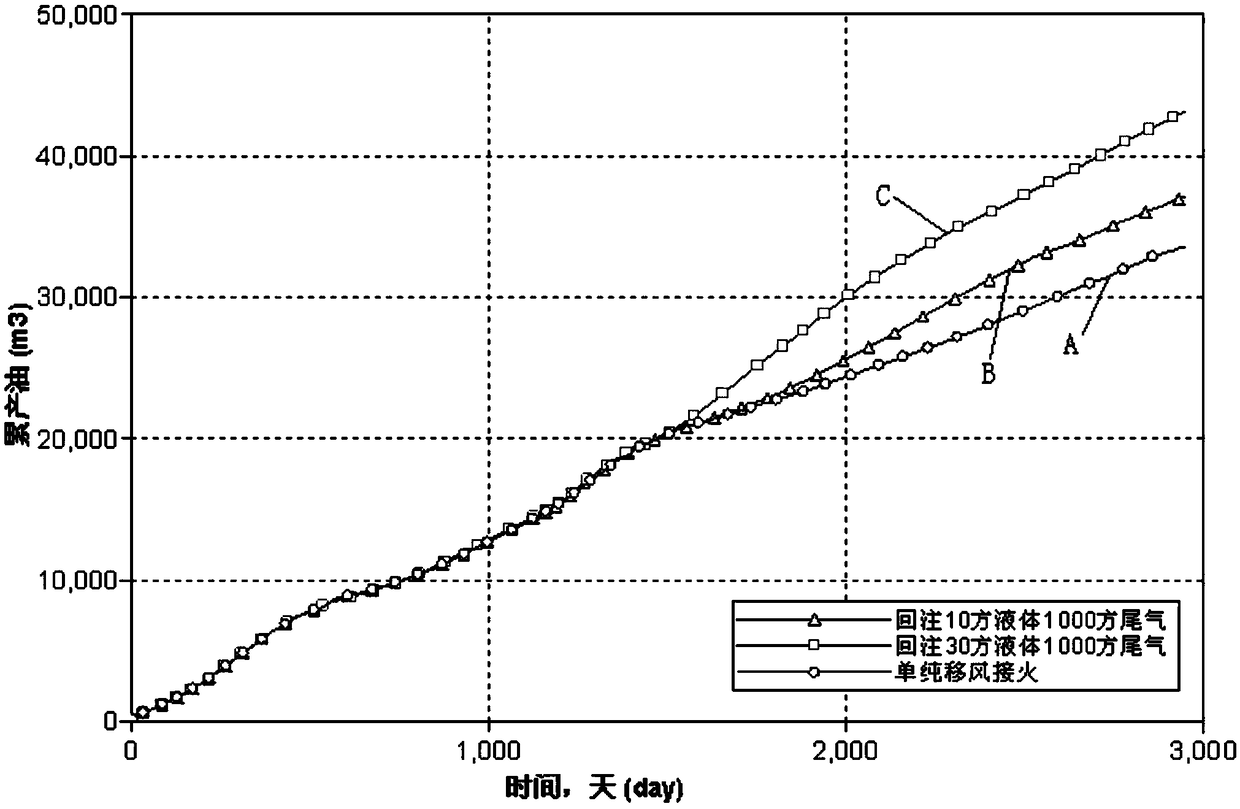

Examples

Embodiment

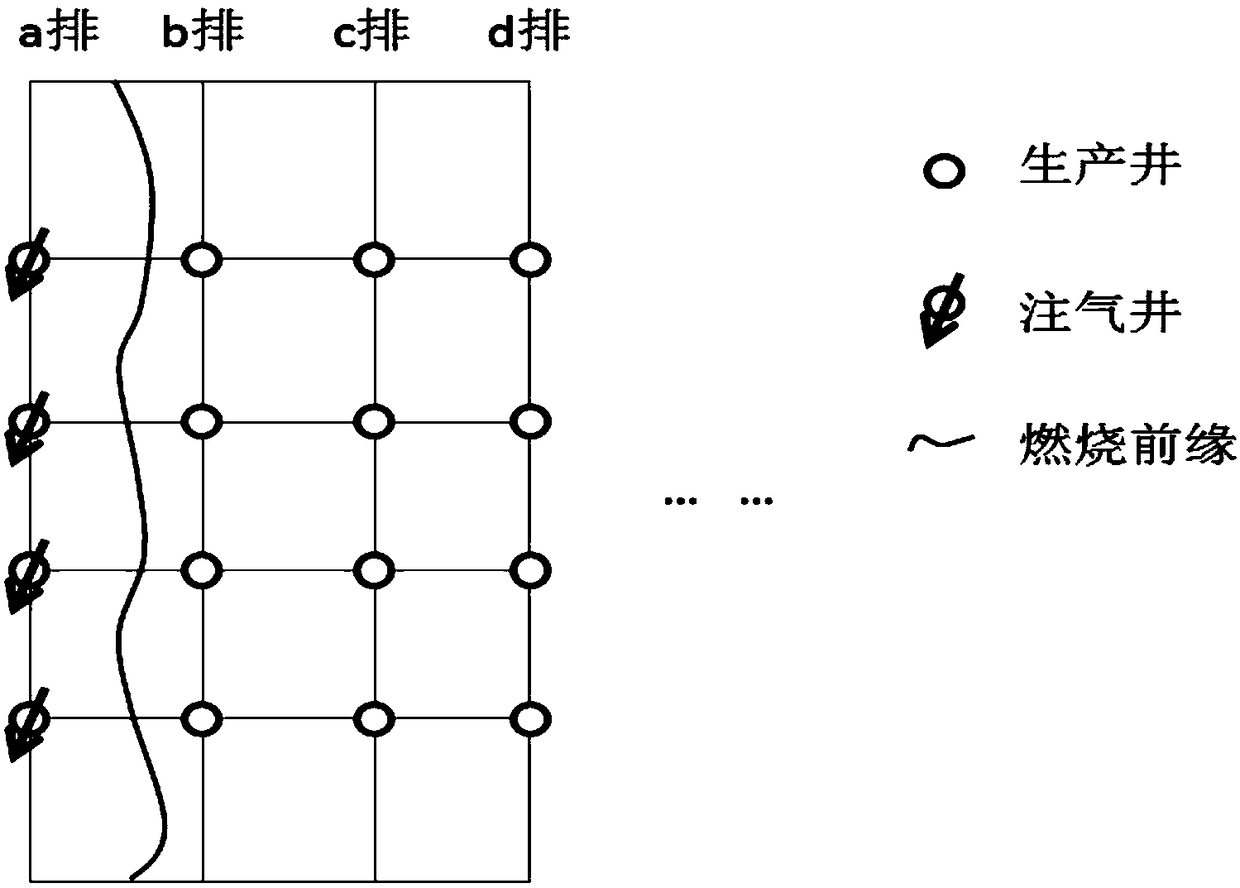

[0036] refer to figure 1 with figure 2 , is a schematic diagram of the well pattern layout in this embodiment, in figure 1 , there are at least 2 rows of production wells in the well pattern. According to this linear fire flooding process, each row of wells is divided separately and marked as row a, row b, row c, row d..., row a is the first row of gas injection wells; row b and row c , row d...respectively as the first row of production well row, the second row of production well row, the third row of production well row...;

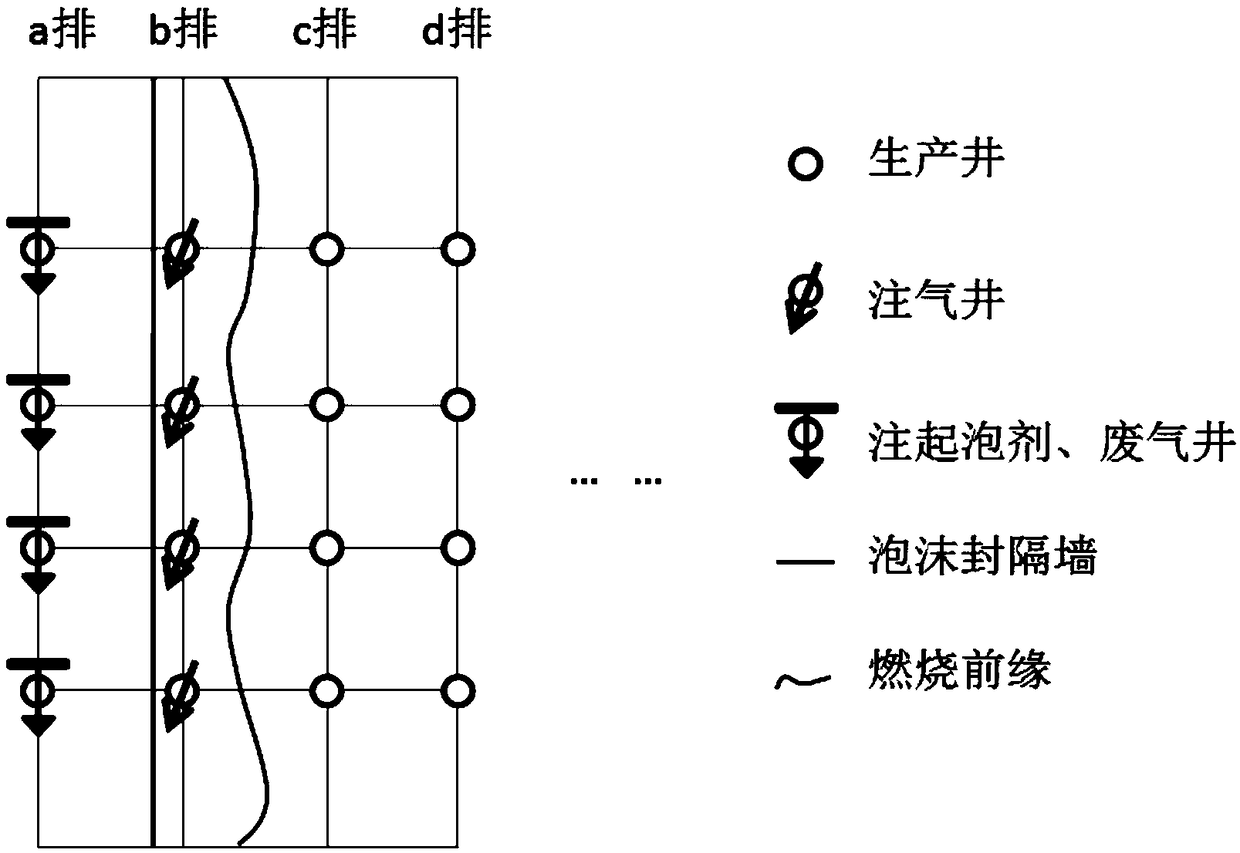

[0037] Carry out ignition and gas injection to row a, and when the combustion front crosses row b, change row b to gas injection well row, and change row a to reinjection wells for injecting foam liquid and fire-driven tail gas;

[0038] Inject the foam liquid and fire drive exhaust gas from row a through the slug injection method, and the injected foam liquid forms a foam partition wall between row a and row b, and the foam partition wall connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com