A method of secondary lining construction without formwork for tunnels using laminated slab technology

A technology of secondary lining and construction method, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., which can solve the problems of long construction period, poor adaptability of heterogeneous sections, and large occupied space, so as to save construction space, improve adaptability, save template effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

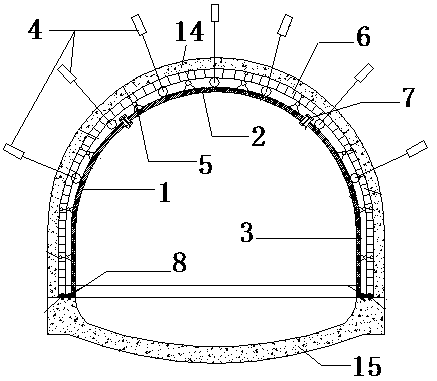

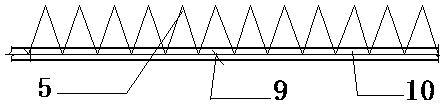

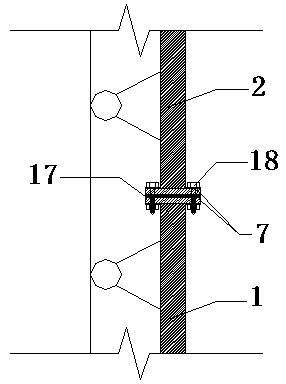

[0032] Embodiment 1: as Figure 1-12 As shown, a formwork-free secondary lining construction method for tunnels using laminated slab technology. Before the secondary lining construction, the laminated slabs are prefabricated in sections; during the initial support construction, anchor connectors are pre-embedded inside the surrounding rock ; Then assemble the prefabricated laminated slabs in pieces, the prefabricated laminated slabs are anchored and connected by the reserved steel plates, the laminated slabs are fixed on the surrounding rock and the initial support through the pre-embedded anchor connectors, and the two ends of the laminated slabs are connected with the inverted arch; After the laminated slab is assembled and fixed, insert the pre-bound steel bars between the initial support and the laminated slab, connect the structural bars on the laminated slab with the inserted steel bars, and then install the sealing formwork on the side and pour concrete; After the final...

Embodiment 2

[0051] Embodiment 2: as Figure 1-12 As shown, a formwork-free secondary lining construction method for tunnels using laminated slab technology, this embodiment is the same as Embodiment 1, wherein:

[0052] Further, the longitudinal width of the laminated board is 4 meters; the thickness of the laminated board is 8 cm. Post-casting belt 11 width 80cm.

Embodiment 3

[0053] Embodiment 3: as Figure 1-12 As shown, a formwork-free secondary lining construction method for tunnels using laminated slab technology, this embodiment is the same as Embodiment 1, wherein:

[0054] Further, the longitudinal width of the laminated board is 3.5 meters; the thickness of the laminated board is 6 cm. Post-casting belt 11 width 60cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com