Oil filtration intelligent test platform device

A test platform and intelligent technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, fluid pressure actuation system components, etc., can solve problems such as unsatisfactory filtering effect, large equipment occupation space, equipment damage, etc. Achieve the effect of meeting high-precision customization requirements, reducing production input costs, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

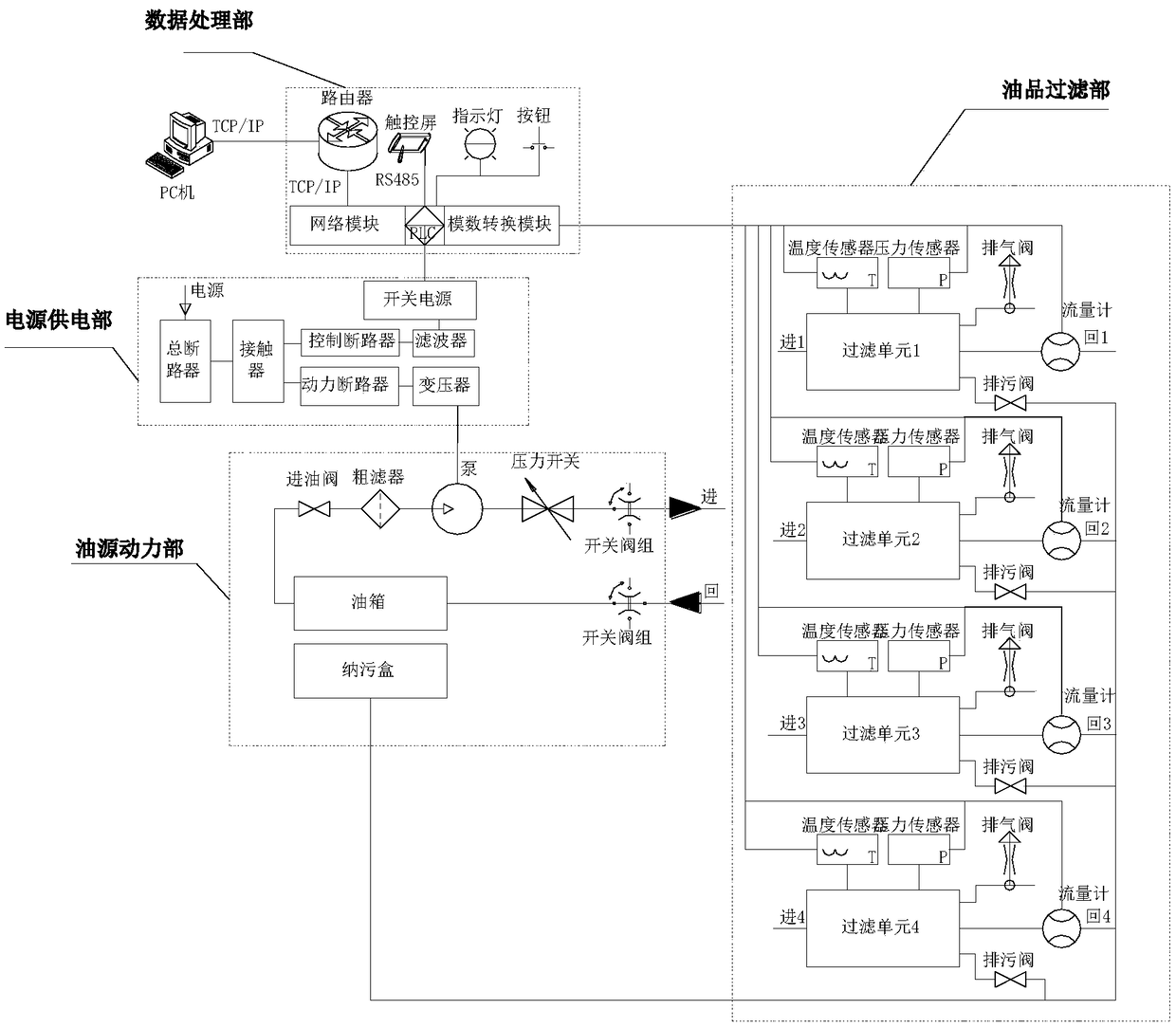

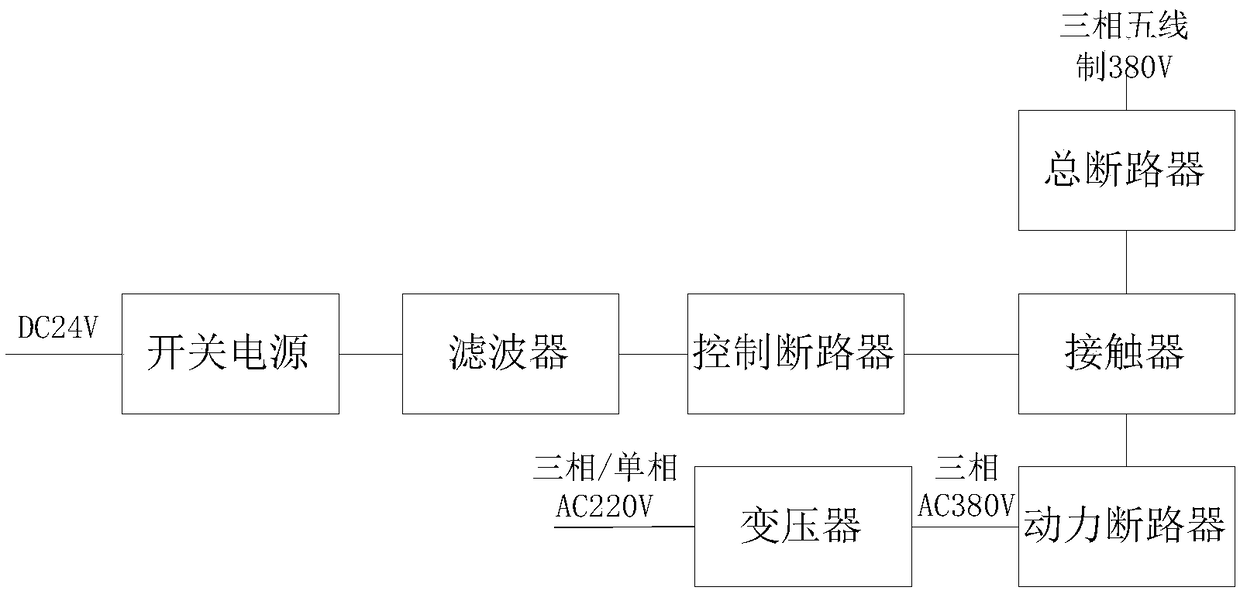

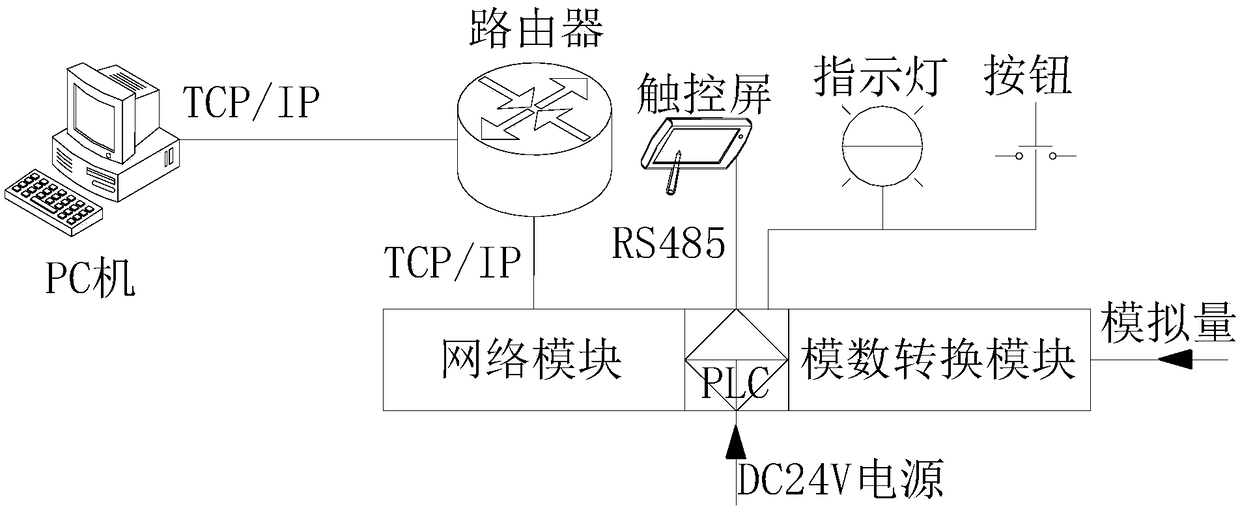

[0036] Referring to the accompanying drawings, an intelligent test platform device for oil filtration includes an oil source power unit and an oil filter unit. The oil source power unit is responsible for the oil source in and out of the platform and power drive. The oil source power unit includes an oil tank, One end of the oil tank is connected in series with the pump unit through a pipeline to the oil inlet of the oil filter unit, and a coarse filter is installed in series on the connecting pipeline between the fuel tank and the pump unit, and the coarse filter adopts a 10um specification filter element, the oil tank is set to be removable with a capacity of 2000L, the primary filtration of the oil source is realized by using a coarse filter of 10um filter element, and the service life of the pump unit is increased. The oil outlet is connected, the oil inlet valve is installed at the oil outlet of the oil tank, and the pressure switch is installed at the oil outlet of the pu...

Embodiment 2

[0043] See attached Figure 5 , On the basis of the technical solution of Example 1, the filter unit includes several groups of filter cores with different precision grades, the filter unit 1 includes filter core specifications that are 40um, 10um, 2um and 0.5um, and the filter unit 2 includes filter core specifications that are 20um, 10um, 2um and 0.5um, filter unit 3 includes filter elements with specifications of 20um, 10um, 2um and 0.2um, filter unit 4 includes filter elements with specifications of 20um, 10um, 2um and 0.2um, and filter elements in the same filter unit use Connected in series, each group of filter elements of the same precision level of different filter units is connected in series through the oil circuit, the filter element with low precision is installed before the filter element with high precision, and the second on-off valve is installed on the oil circuit between the filter elements of each group group, the second switching valve group is used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com