Industrial furnace device

A technology for industrial furnaces and furnaces, which is applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of difficult control of the shell temperature of the furnace, affecting the practical life of the device, and the absence of a cooling system. Maintenance, prevention of affecting service life, and the effect of wide temperature control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

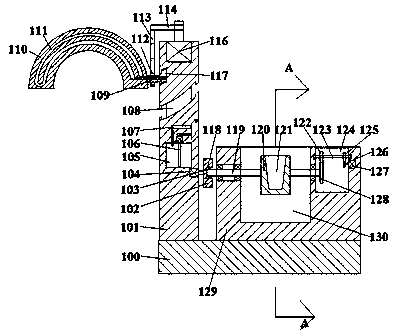

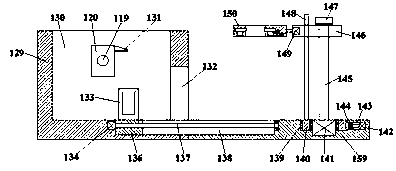

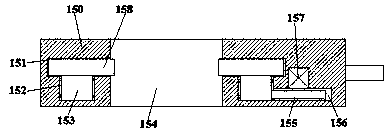

[0014] Such as figure 1 , figure 2 with image 3 As shown, an industrial furnace device of the present invention includes a base 100 and a supporting column 101 arranged on the top end of the base 100 and extending up and down. The top end of the base 100 is provided with the supporting column. The furnace barrel 129 at the right end of 101, the furnace barrel 129 is provided with an upwardly opening furnace cavity 130, the inner wall of the front end of the furnace barrel 129 is penetrated with a discharge port 132, and the front end of the furnace barrel 129 is provided with a The bottom plate 159 on the top of the base 100, the variable speed chamber 124 at the right end of the furnace chamber 130, the first rotating shaft 119 extending left and right is connected to the furnace chamber 130 for rotation, and the left end of the first rotating shaft 119 penetrates The left end of the furnace barrel 129 is provided with a voltage phase change plate 103 in the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com