A fiber-optic ultra-high temperature pressure sensor with temperature compensation function

A technology of pressure sensor and temperature compensation, which is applied in the direction of fluid pressure measurement of elastic deformation gauge, measurement of fluid pressure, measurement of fluid pressure through mechanical components, etc. Developed ultra-high temperature pressure sensors, did not form mature products, and blocked high-tech technology to achieve good chemical stability, avoid adverse effects, high natural frequency and fast response capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

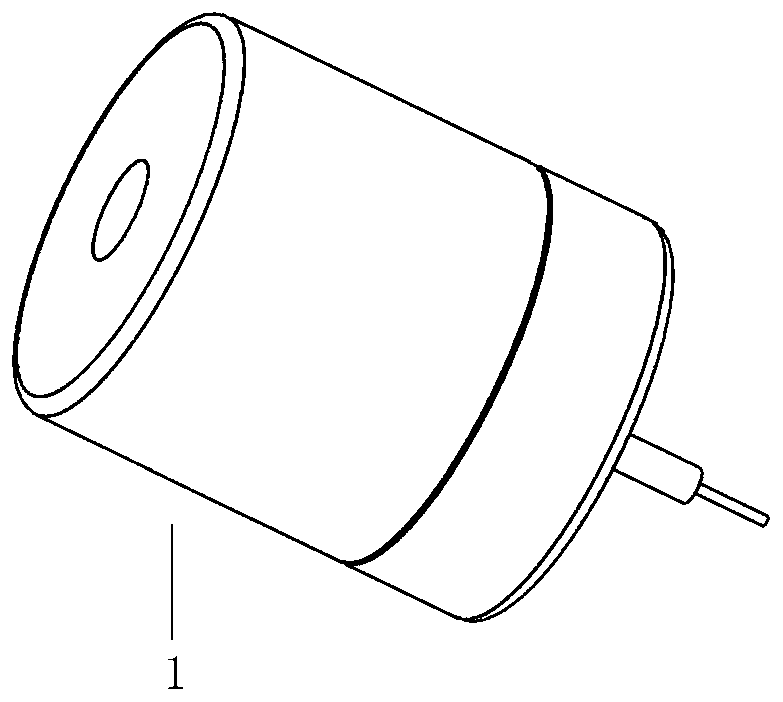

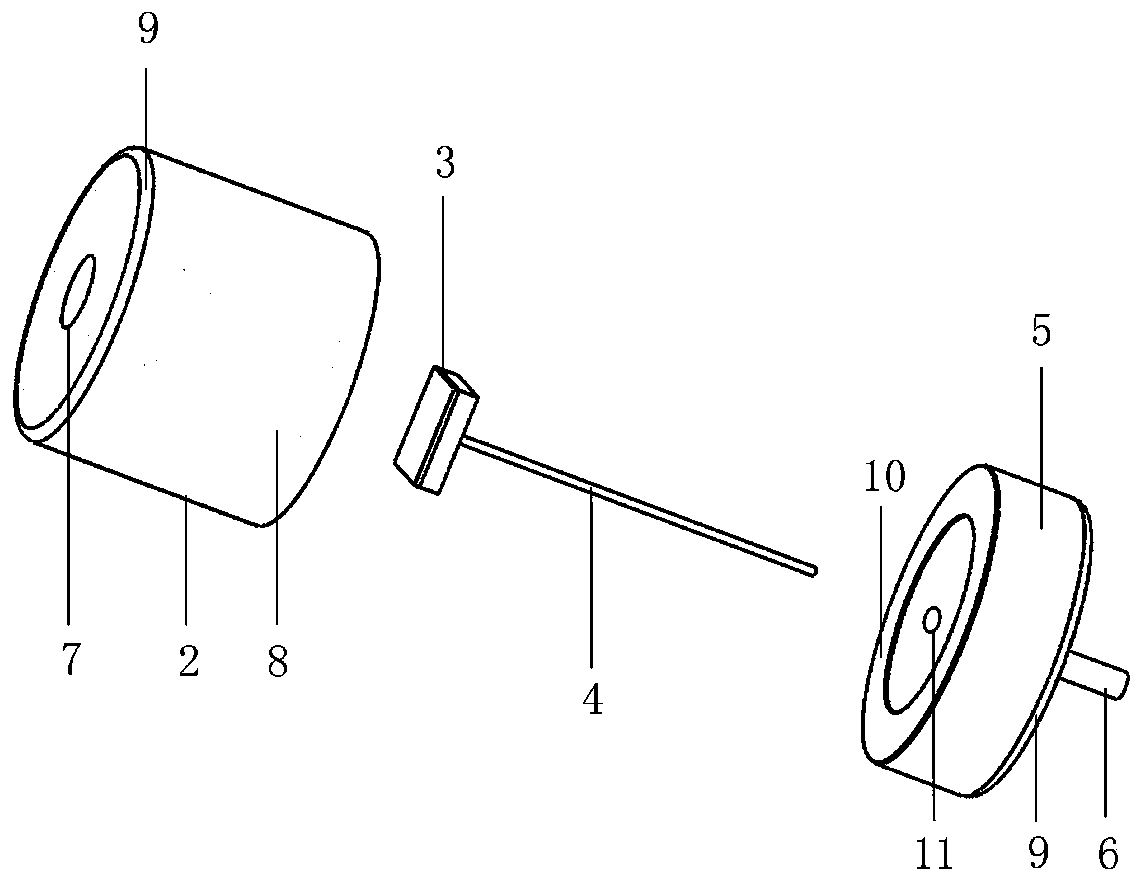

[0025] refer to figure 1 with figure 2 , a fiber-optic ultra-high temperature pressure sensor 1 with temperature compensation function, including a sensor chip 3, the signal output of the sensor chip 3 is connected to a high-temperature-resistant optical fiber 4, the sensor chip 3 is installed in the sensor probe 2, and the high-temperature-resistant optical fiber 4 passes through the package The board 5 and the optical fiber sleeve 6 are connected to the packaging board 5 , and the packaging board 5 is connected to the sensor probe 2 to realize the packaging of the sensor chip 3 and the high temperature resistant optical fiber 4 .

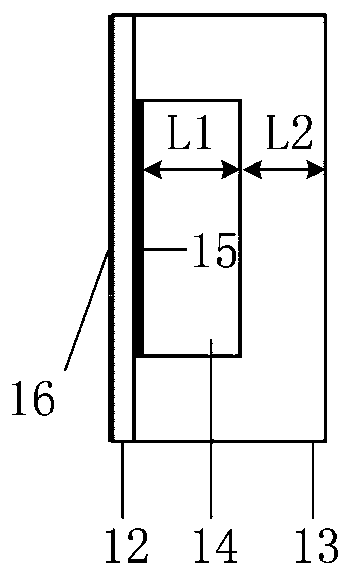

[0026] The sensor probe 2 is cylindrical, and the front surface of the sensor probe 2 and the inside are respectively provided with a pressure introduction hole 7 and a sensor chip mounting groove 8, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com