Technology of soybean peeling and enzyme killing with microwave method

A microwave method, soybean technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of high energy consumption and long time for enzyme inactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of microwave method carries out the technology of soybean dehulling and deenzyme, it is characterized in that comprising the following steps:

[0031] (1) Pre-treatment: cleaning, stone removal and selection of soybean raw materials;

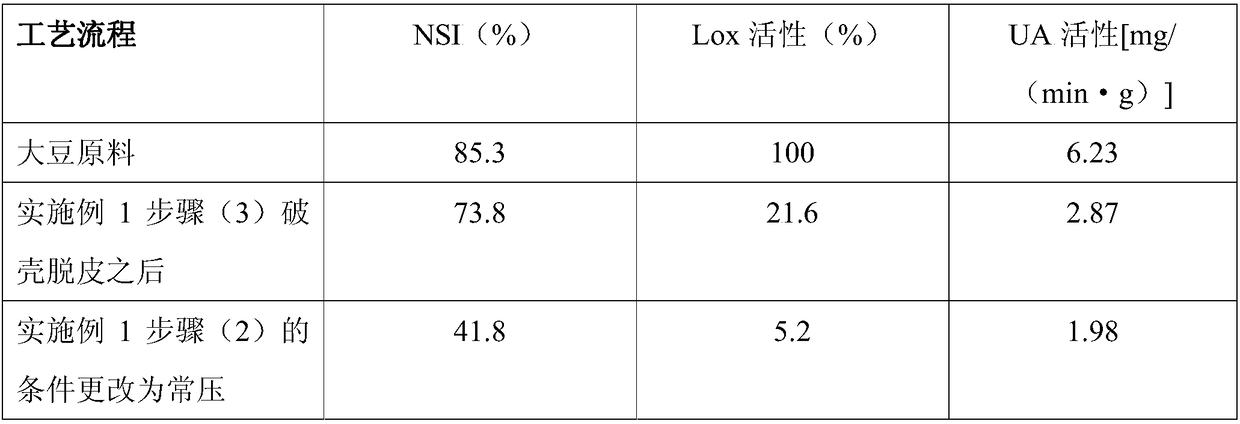

[0032] (2) Shell breaking: the skinned soybeans obtained in step (1) are placed in a microwave treatment device, and the microwave power is 2.0kW, and the vacuum is 60kPa, and the microwave treatment is 60s;

[0033] (3) Dehulling: Carry out winnowing and dehulling to obtain dehulled soybeans;

[0034] (4) Soaking: Soak the dehulled soybeans in distilled water for 20 hours;

[0035] (5) Drain: Drain the moisture on the surface of the peeled soybean naturally;

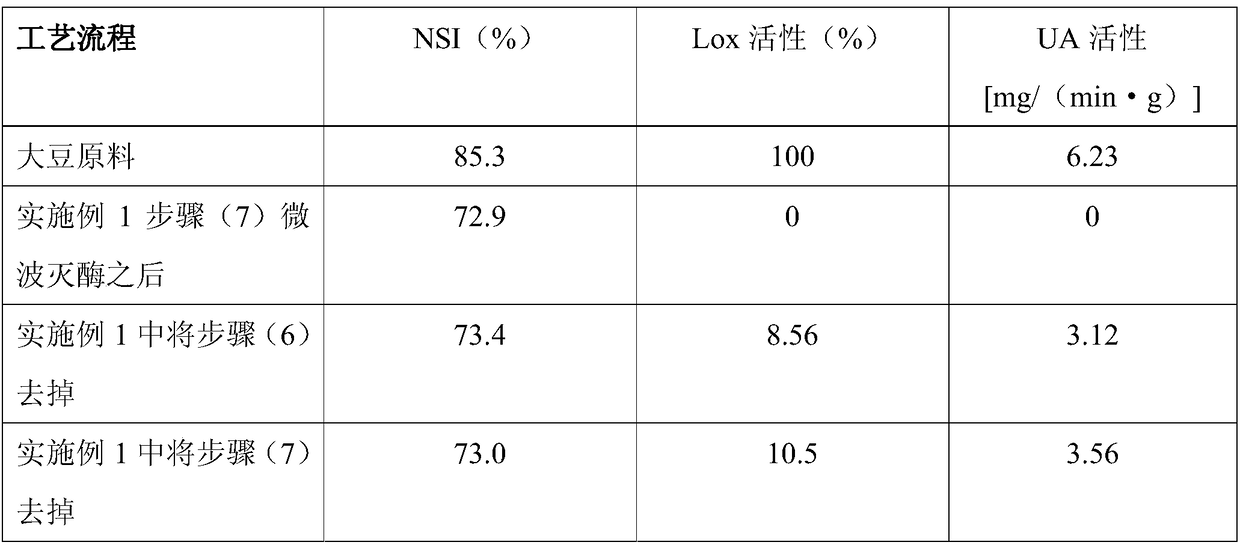

[0036] (6) Enzyme elimination by steaming; the soybean obtained in step (5) is placed in a steam generating device, the steam temperature is 90° C., and the treatment time is 3 minutes;

[0037] (7) Microwave inactivating enzyme: the soybean obtained in step (6) is placed...

Embodiment 2

[0056] A kind of microwave method carries out the technology of soybean dehulling and deenzyme, it is characterized in that comprising the following steps:

[0057] (1) Pre-treatment: cleaning, stone removal and selection of soybean raw materials;

[0058] (2) Shell breaking: the skinned soybeans obtained in step (1) are placed in a microwave treatment device, and the microwave power is 1.5kW, and the vacuum is 45kPa, and the microwave treatment is 70s;

[0059] (3) Dehulling: Carry out winnowing and dehulling to obtain dehulled soybeans;

[0060] (4) Soaking: Soak the dehulled soybeans in distilled water for 24 hours;

[0061] (5) Drain: Drain the moisture on the surface of the peeled soybean naturally;

[0062] (6) Enzyme elimination by steaming; the soybean obtained in step (5) is placed in a steam generating device, the steam temperature is 80° C., and the treatment time is 5 min;

[0063](7) Microwave inactivating enzyme: the soybean obtained in step (6) is placed in a...

Embodiment 3

[0076] A kind of microwave method carries out the technology of soybean dehulling and deenzyme, it is characterized in that comprising the following steps:

[0077] (1) Pre-treatment: cleaning, stone removal and selection of soybean raw materials;

[0078] (2) Shell breaking: the skinned soybeans obtained in step (1) are placed in a microwave treatment device, and the microwave power is 2.0kW, and the vacuum is 60kPa, and the microwave treatment is 60s;

[0079] (3) Dehulling: Carry out winnowing and dehulling to obtain dehulled soybeans;

[0080] (4) Soaking: Soak the dehulled soybeans in distilled water for 20 hours;

[0081] (5) Drain: Drain the moisture on the surface of the peeled soybean naturally;

[0082] (6) Enzyme elimination by steaming; the soybean obtained in step (5) is placed in a steam generating device, the steam temperature is 90° C., and the treatment time is 3 minutes;

[0083] (7) Microwave inactivating enzyme: the soybean obtained in step (6) is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com