Road concrete transportation and stirring device and using method thereof

A mixing device and concrete technology, which is applied in the direction of cement mixing device, mixing operation control device, transportation and packaging, etc., can solve the problems of high space requirements, low space utilization rate, complex product structure, etc., and achieve compact structure and realize Stirring uniformity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

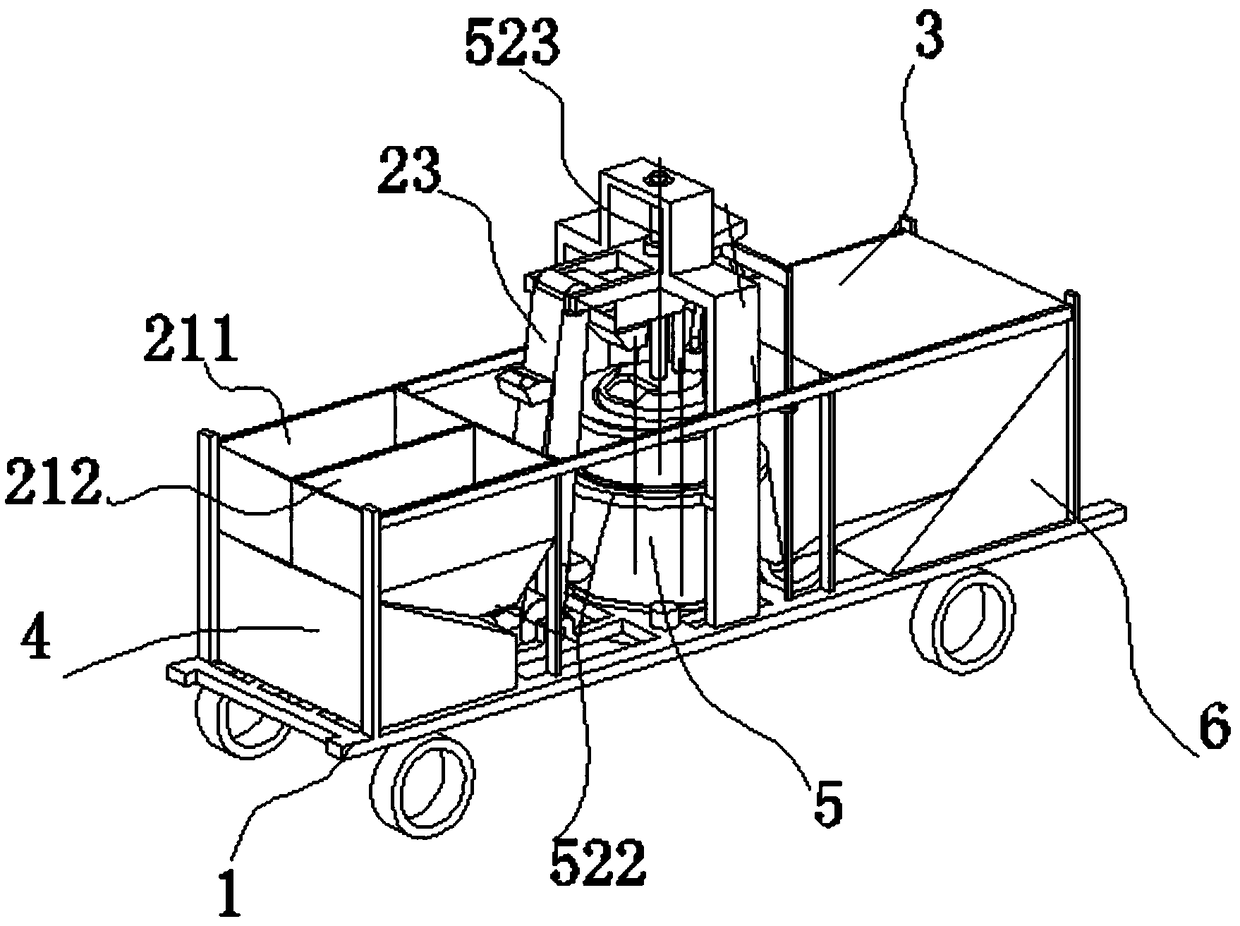

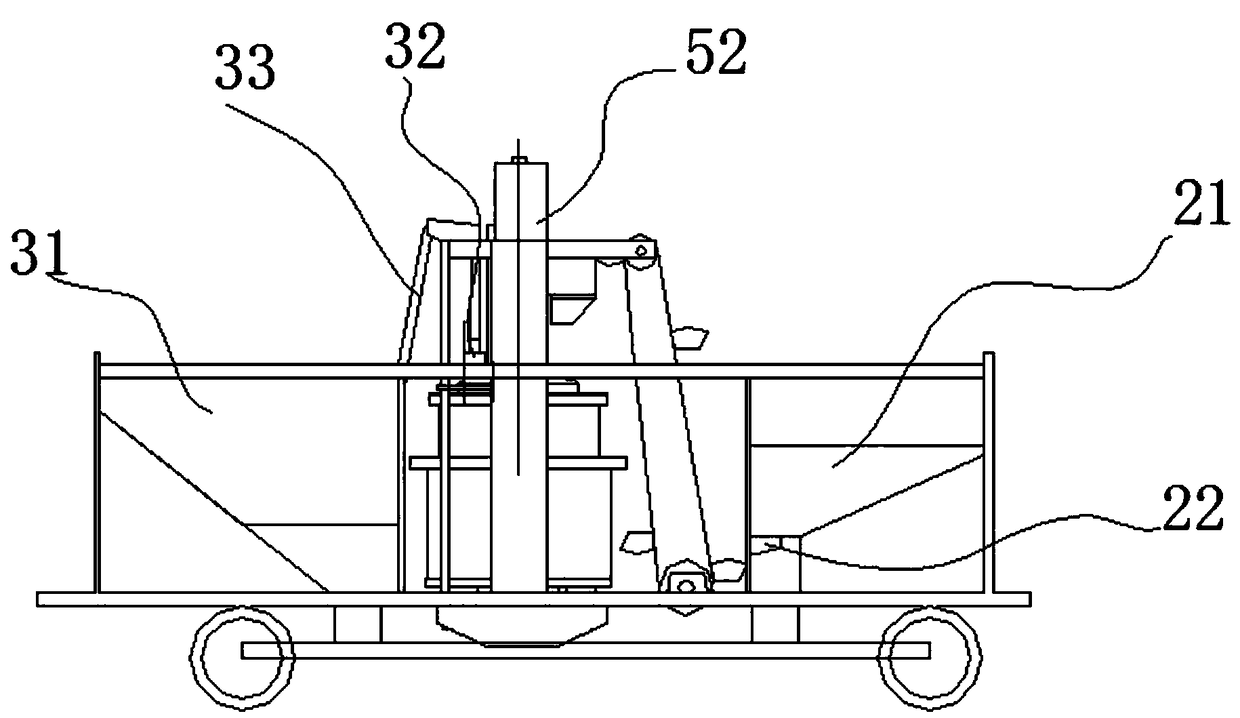

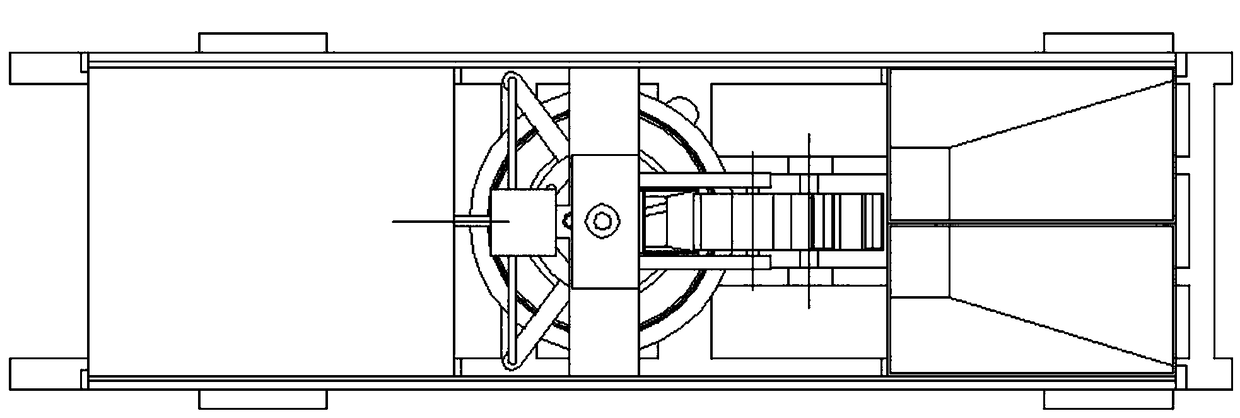

[0048] A mixing device for road concrete transportation, comprising a chassis, a base support 1 and a mixing system 5; the base support 1 is fixed on the chassis; the mixing system 5 is fixed on the base support 1; and an aggregate storage supply system is also included 2. Powder storage and supply system 3, liquid storage and supply system 4, control module 6 and cleaning system 7; the aggregate storage and supply system 2, powder storage and supply system 3, and liquid storage and supply system 4 are all fixed on the base bracket 1 and are connected to the stirring system 5; the cleaning system 7 is connected to the liquid storage supply system 4; the aggregate storage supply system 2, the powder storage supply system 3, the liquid storage supply system 4, and the stirring system 5 And the cleaning system 7 is connected with the control module 6; the stirring system 5 includes a stirring device 51; the cleaning system 7 includes a nozzle; the nozzle is located inside the stir...

Embodiment 2

[0057] With embodiment 1, difference is:

[0058] The water pressure of the cleaning system 7 is set to P / Mpa, the vertical distance from the nozzle to the cleaning position is C / cm, and the horizontal distance is D / cm. The relationship between them satisfies: Among them, ε takes 7.2.

[0059] The gap between the upper mixing drum 512 and the lower mixing drum 511 is 1.2 cm, the wall thickness of the upper mixing drum 512 is 4 cm, the wall thickness of the lower mixing drum 511 is 5 cm, and the inner wall radius of the lower mixing drum is 100 cm.

[0060] When the equipment of this embodiment is applied to a road reconstruction project, the pavement on site is 8m wide, 12cm thick, and 600m in length; After being taken to the road concrete transport mixing device at a speed of 50km per hour and arriving at the operation site within 1 hour, it is quickly debugged and put into production, which is completed within 1 hour; the power unit is started, and an excavator is used to ...

Embodiment 3

[0062] With embodiment 1, the difference is

[0063] The water pressure of the cleaning system 7 is set to P / Mpa, the vertical distance from the nozzle to the cleaning position is C / cm, and the horizontal distance is D / cm. The relationship between them satisfies: Where ε takes 2.

[0064] When the equipment of this embodiment is applied to a certain road reconstruction project, the on-site pavement is 10m wide, 15cm thick, and 400m long; the road concrete transport mixer is about 75km away from the construction site, and the road concrete transport mixer, tractor After being taken to the road concrete transport mixing device at a speed of 50km per hour and arriving at the operation site after 1.5 hours, it was quickly debugged and put into production, which was completed within 1 hour; the power unit was started, and an excavator was used to add raw materials to it, and at the same time , the power device drives the screw to rotate, drives the upper mixing drum 512 to rise, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com