Servo-driven three-cutter mechanical shock high-speed grinder

A mechanical impact and servo-driven technology, applied in grain processing, etc., can solve problems such as low transmission efficiency, torque loss, and limitation of crushing efficiency, and achieve the effects of improving crushing efficiency, preventing excessive wear, and increasing relative speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings.

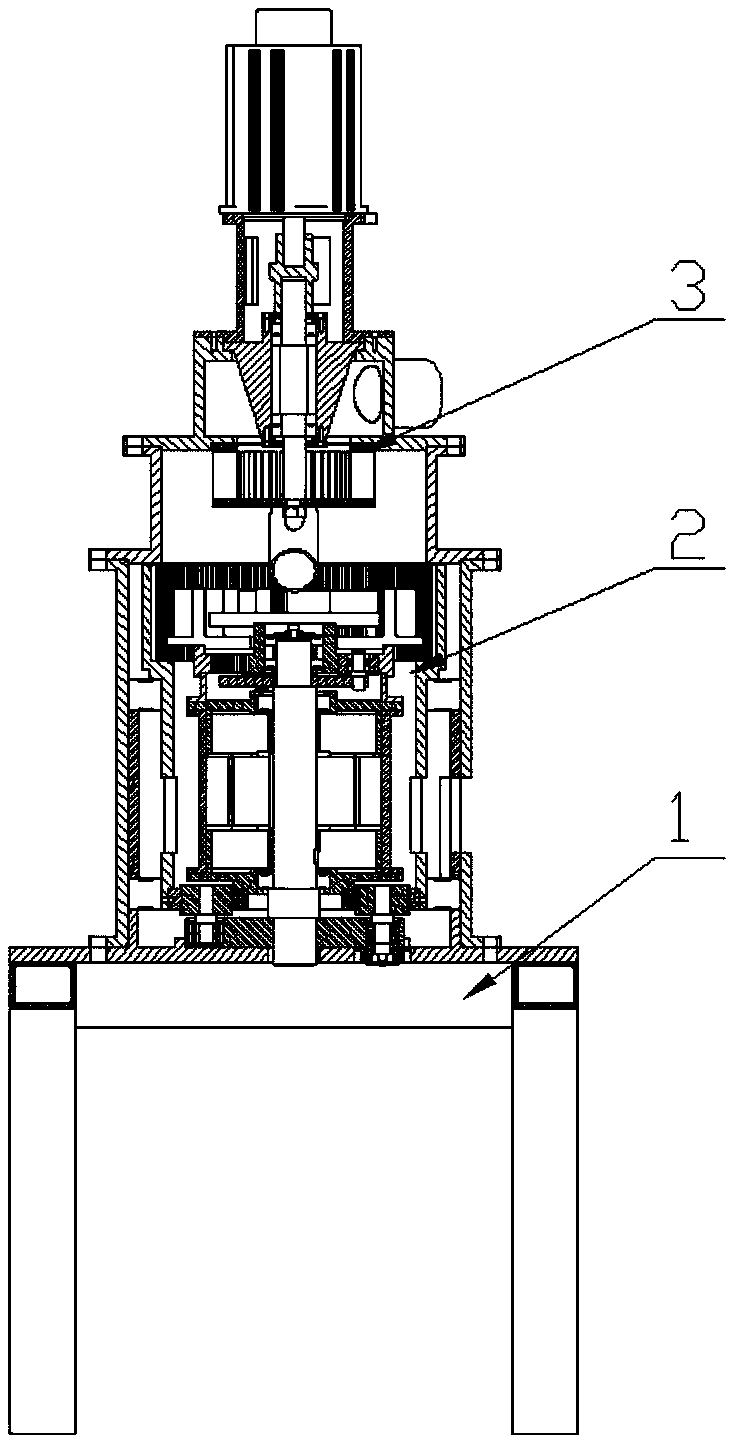

[0031] refer to figure 1 , a servo-driven three-cutter mechanical impact high-speed grinding mill, comprising a frame 1, a crushing device 2 is fixed at the center of the frame 1, and a classifying device 3 is fixed on the top of the crushing device 2;

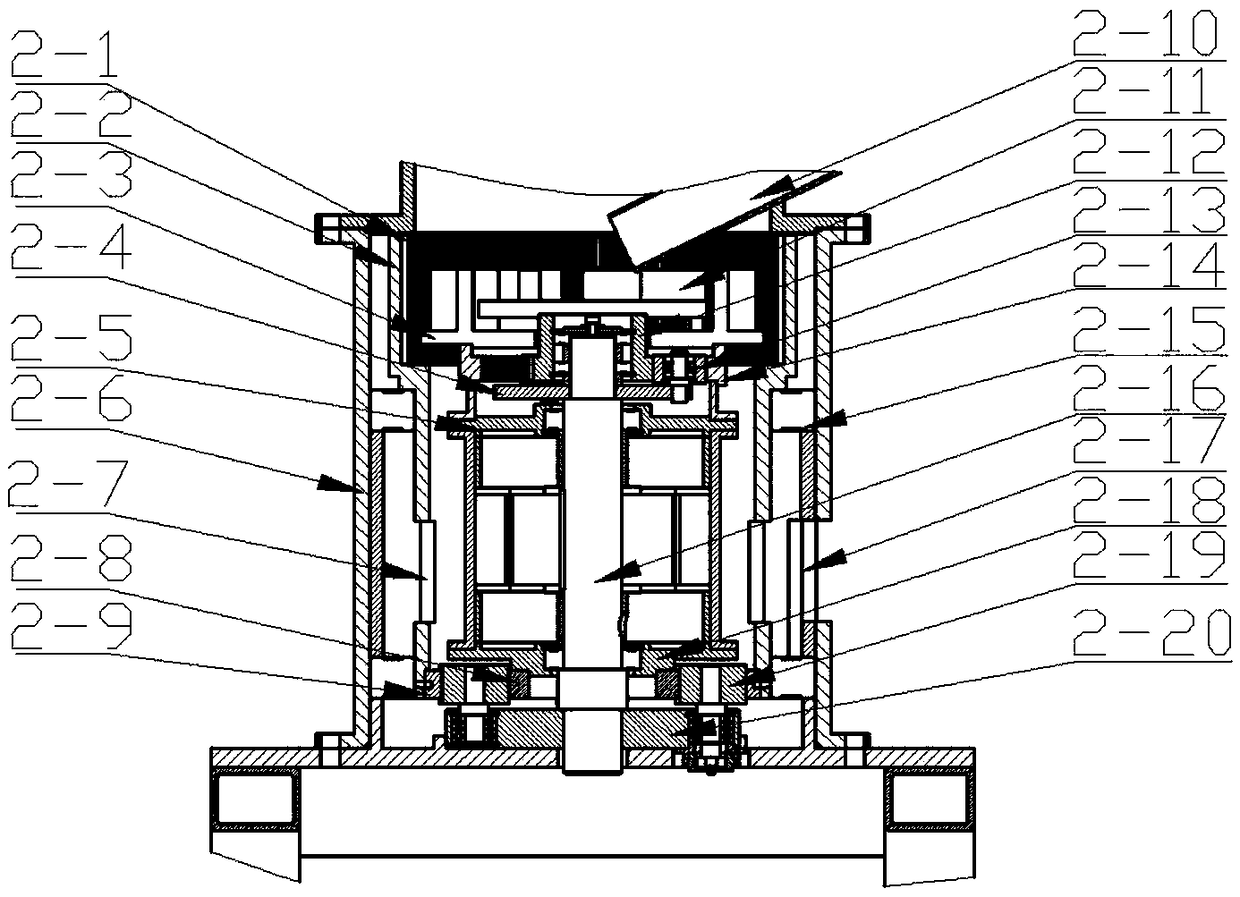

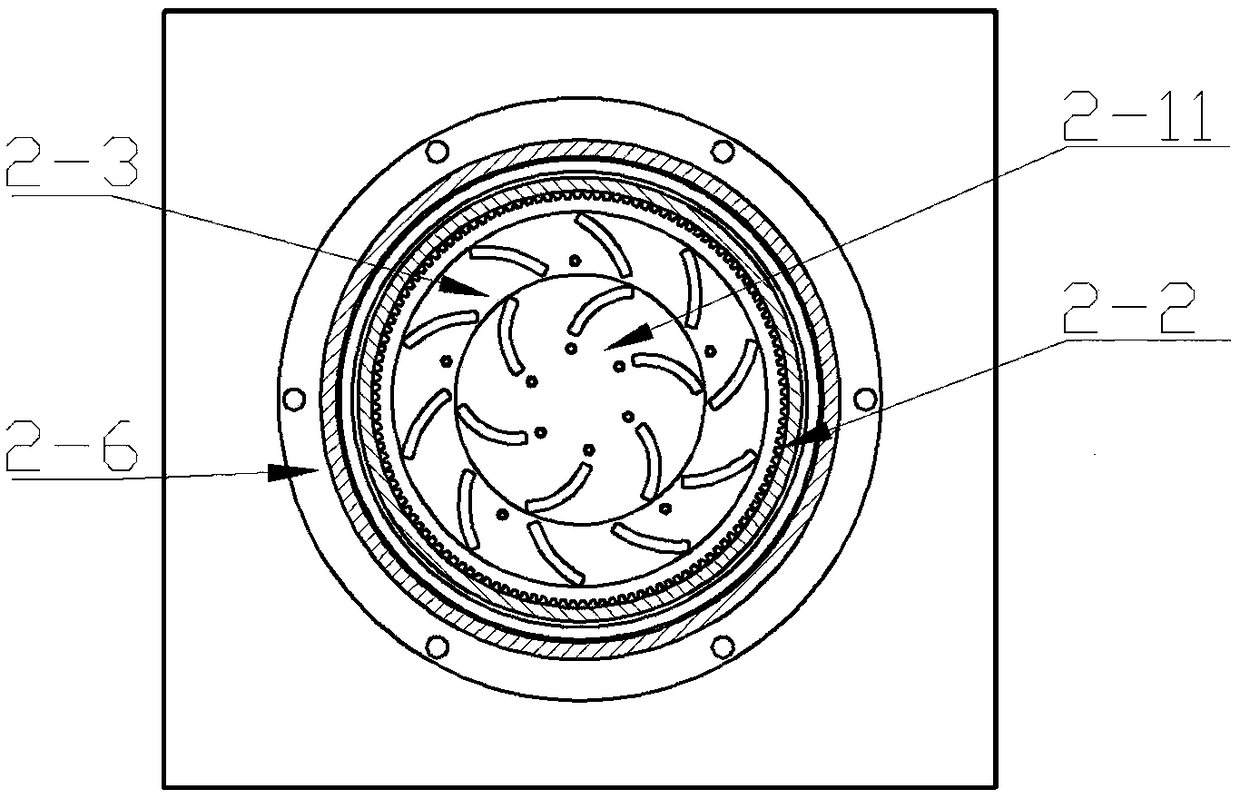

[0032] refer to figure 2 , image 3 , Figure 4 with Figure 5 , the crushing device 2 includes a crushing device outer cylinder 2-6 fixed on the frame 1, the middle part of the crushing device outer cylinder 2-6 is provided with an outer rotor servo motor, and the stator shaft 2-6 of the outer rotor servo motor The bottom of 16 is fixed on the frame 1 by bolts, and the top of the stator shaft 2-16 is connected with the first planetary gear system sun gear 2-12 through bearings, and the first planetary gear system sun gear 2-12 is connected to the first cutter head 2 by bolts. -11 is fixed, the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com