Wire feeding nozzle fixing clamp for automatically feeding wires for manual argon arc welding and welding equipment

A technology of manual argon arc welding and fixing fixtures, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problem of inability to flexibly adjust the wire feeding position and wire feeding angle of the wire feeding nozzle, inconvenient use of welding torches, and inability to guarantee The fastening of the wire feeding nozzle and other problems can be achieved to achieve the effect of compact structure and simple installation and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

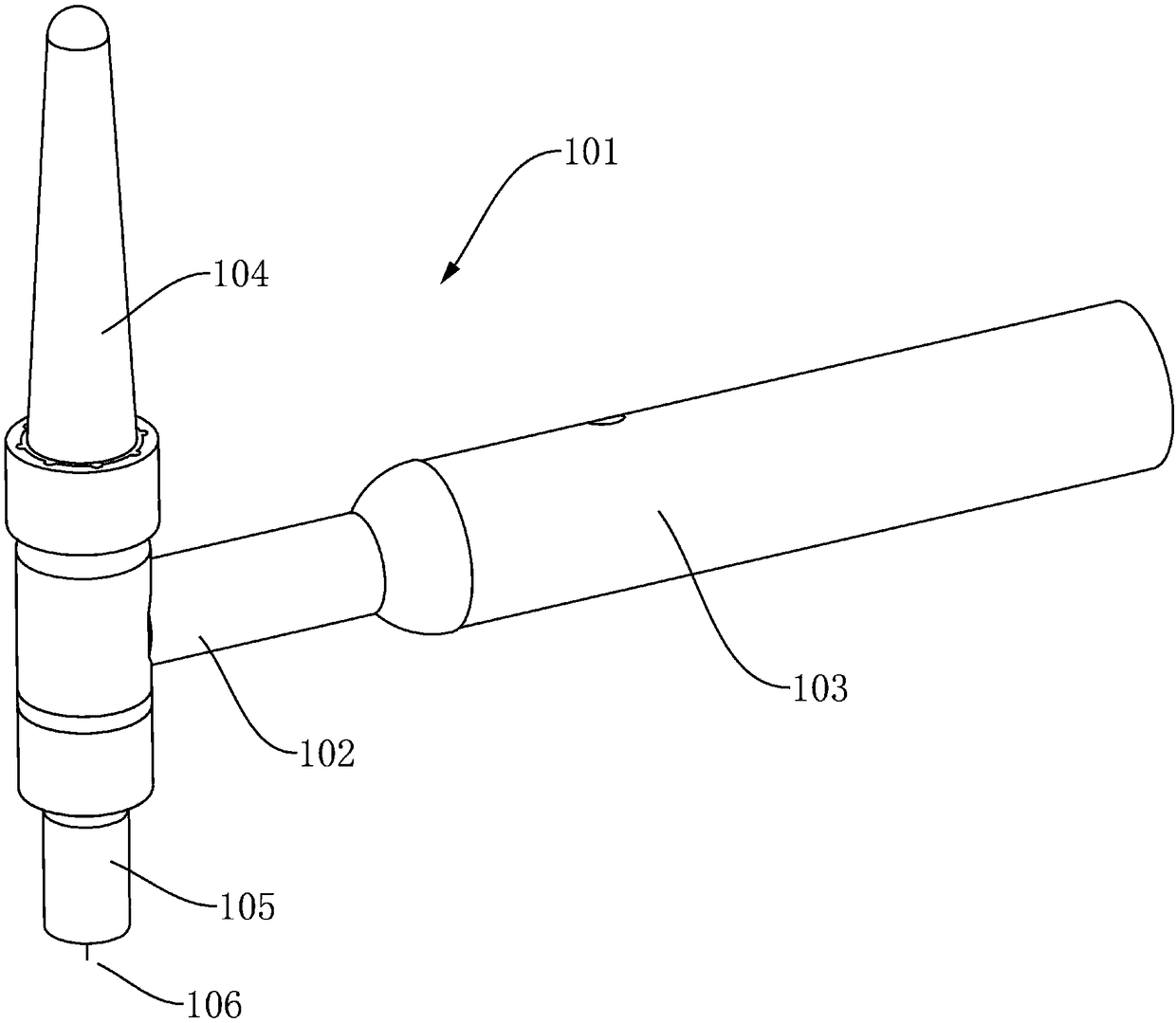

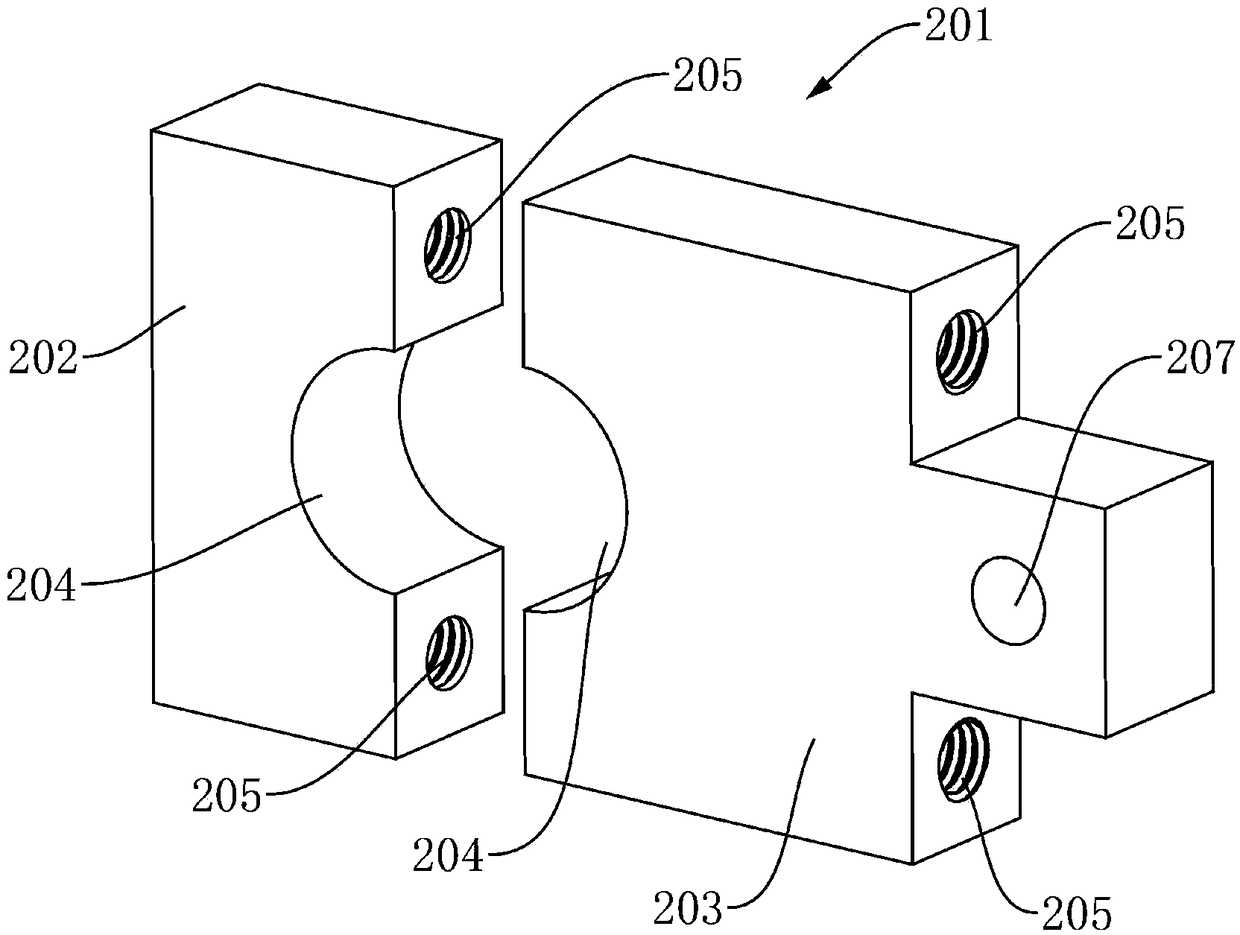

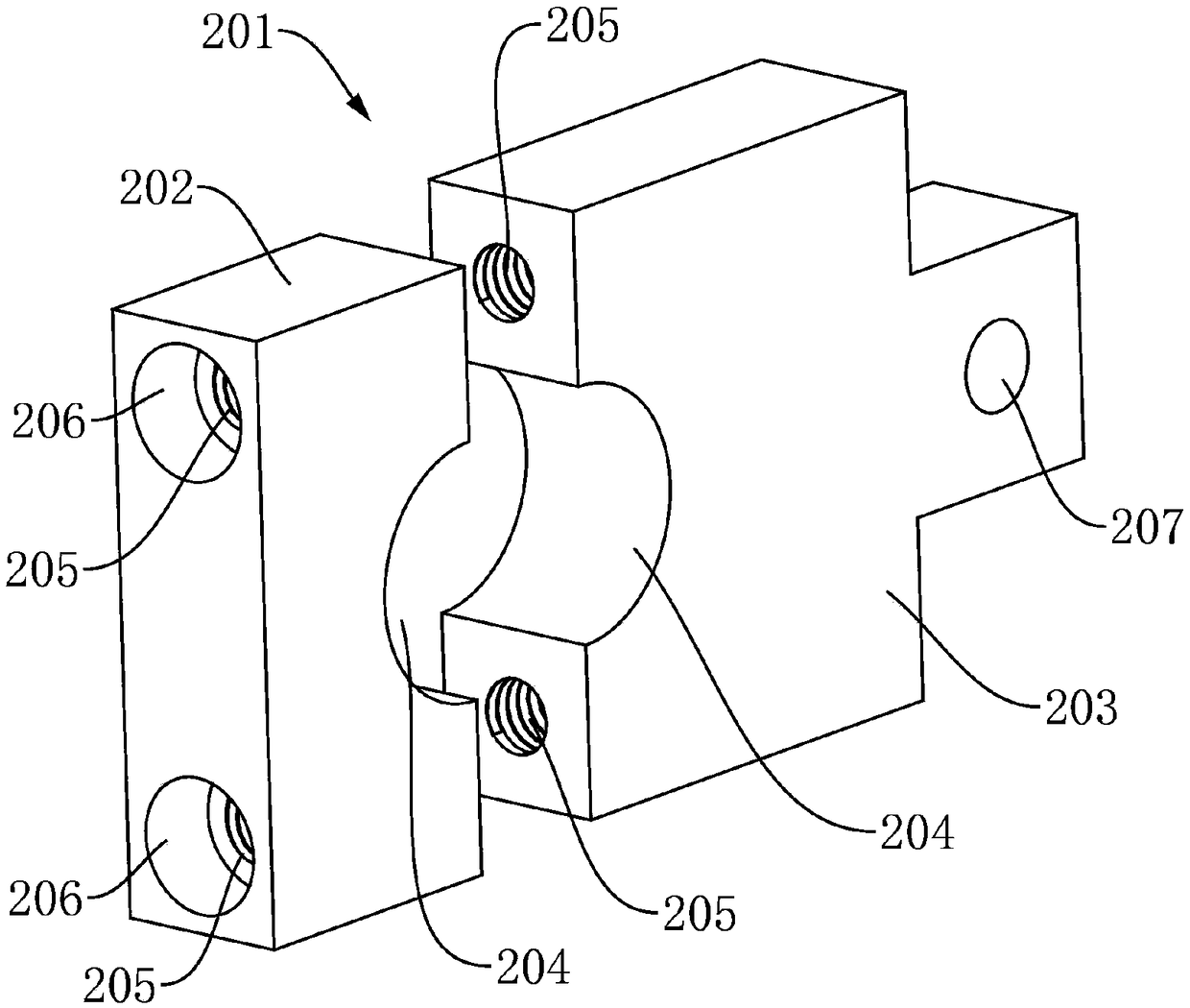

[0049] This embodiment provides a wire feeding nozzle fixing fixture that can be used for manual argon arc welding automatic wire feeding, wherein the clamping part 201 includes two clamping blocks, and the two clamping blocks can be clamped together Function; that is, after the two clamping blocks are paired together, they can surround the clamped part 201, such as the welding torch body 102 of the welding torch 101, so as to realize the fixing of the fixing fixture.

[0050] Such as figure 2 and image 3 As shown, as a preferred solution, the clamping part 201 includes a clamping block 1 202 and a clamping block 2 203, wherein grooves 204 are respectively provided at corresponding positions on the clamping block 1 202 and the clamping block 2 203, and the grooves 204 Both sides are respectively provided with threaded holes 205; when clamping block one 202 and clamping block two 203 are paired together, the groove 204 on clamping block one 202 communicates with the groove 2...

Embodiment 2

[0059] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that this embodiment provides a wire feeding nozzle fixing fixture that can be used for automatic wire feeding in manual argon arc welding, and also includes a base 401. In this embodiment, the clamp Block one 202 and clamping block two 203 are cuboid structures, and the base 401 is a convex structure, such as Figure 10 As shown, the base 401 is fixed to the clamping block 1 202 or the clamping block 2 203 by bolts 107 , and a through hole 207 is provided on the protruding part of the base 401 , and the through hole 207 is used for connecting the fixing frame 301 .

[0060] In this embodiment, the base 401 is used for connecting the clamping part 201 and supporting the fixing frame 301 .

[0061] Such as Figure 11 As shown, in this embodiment, the first clamping block 202, the second clamping block 203, and the base 401 have the same thickness and the same height, which is not only ...

Embodiment 3

[0064] This embodiment provides an automatic wire-feeding argon arc welding equipment, including a welding torch 101, a wire feeding nozzle 501 and the aforementioned fixing fixture, the clamping part 201 of the fixing fixture is clamped on the welding torch 101, and the wire feeding nozzle 501 is set There is an external thread 502, and the wire feeding nozzle 501 passes through the adjusting groove 304 on the fixing frame 301, and is fixed by two adjusting nuts 305, such as Figure 13 shown.

[0065] In this embodiment, the welding torch 101 may be a commonly used welding torch 101 in the prior art, the clamping part 201 is clamped on the welding torch body 102 of the welding torch 101, and one end of the wire feeding nozzle 501 is used to connect with the electrode 106 of the welding torch 101 Matching, the other end is connected with the wire feeding hose, and the wire feeding hose is connected with the main machine of the automatic wire feeding machine so as to automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com