Optical glass mirror grinding equipment

A technology of optical glass and equipment, which is applied in the field of optical glass mirror grinding equipment, can solve the problems of not being able to guarantee the grinding accuracy and being on the same straight line, and achieve the effects of convenient grinding, improving precision and avoiding optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

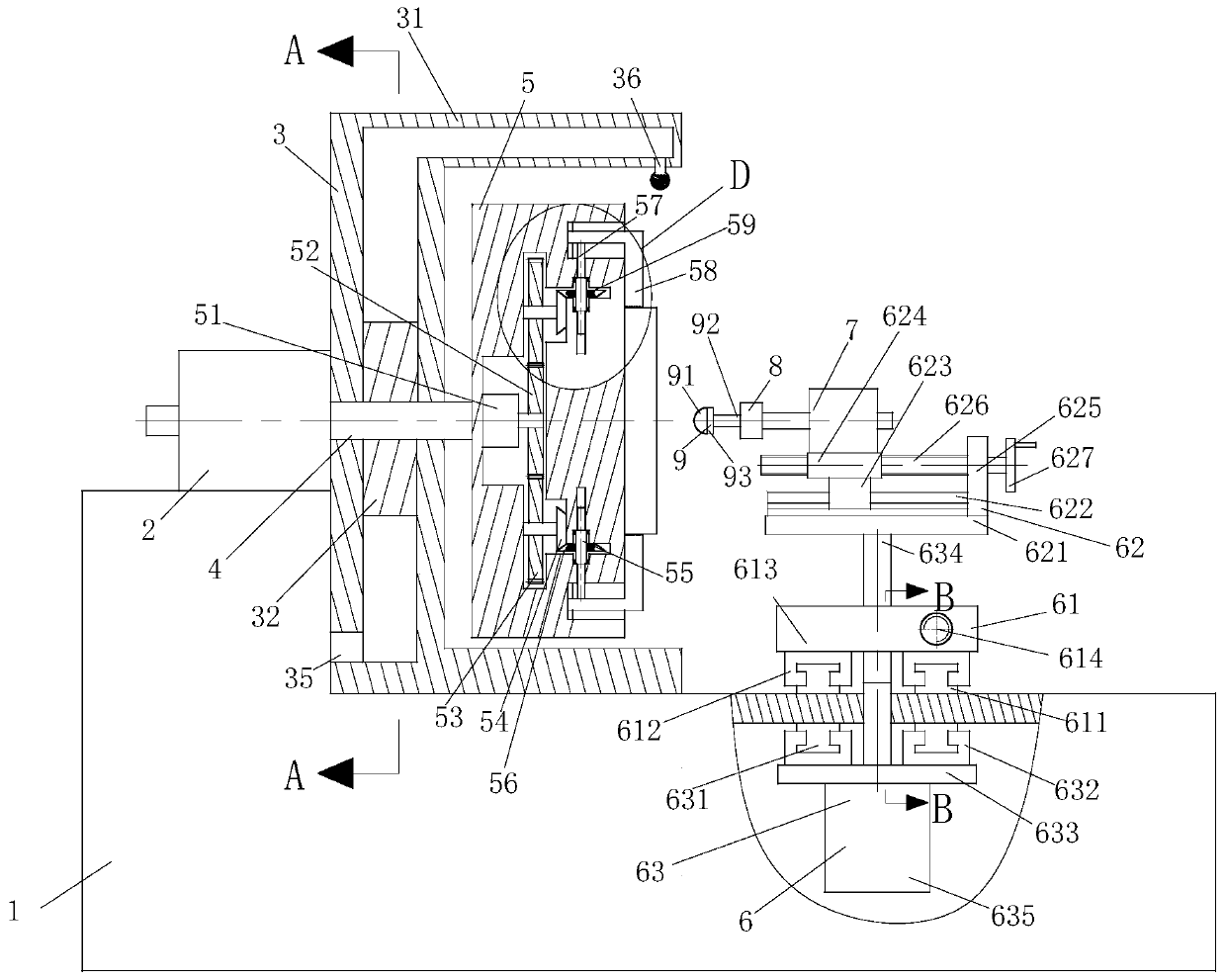

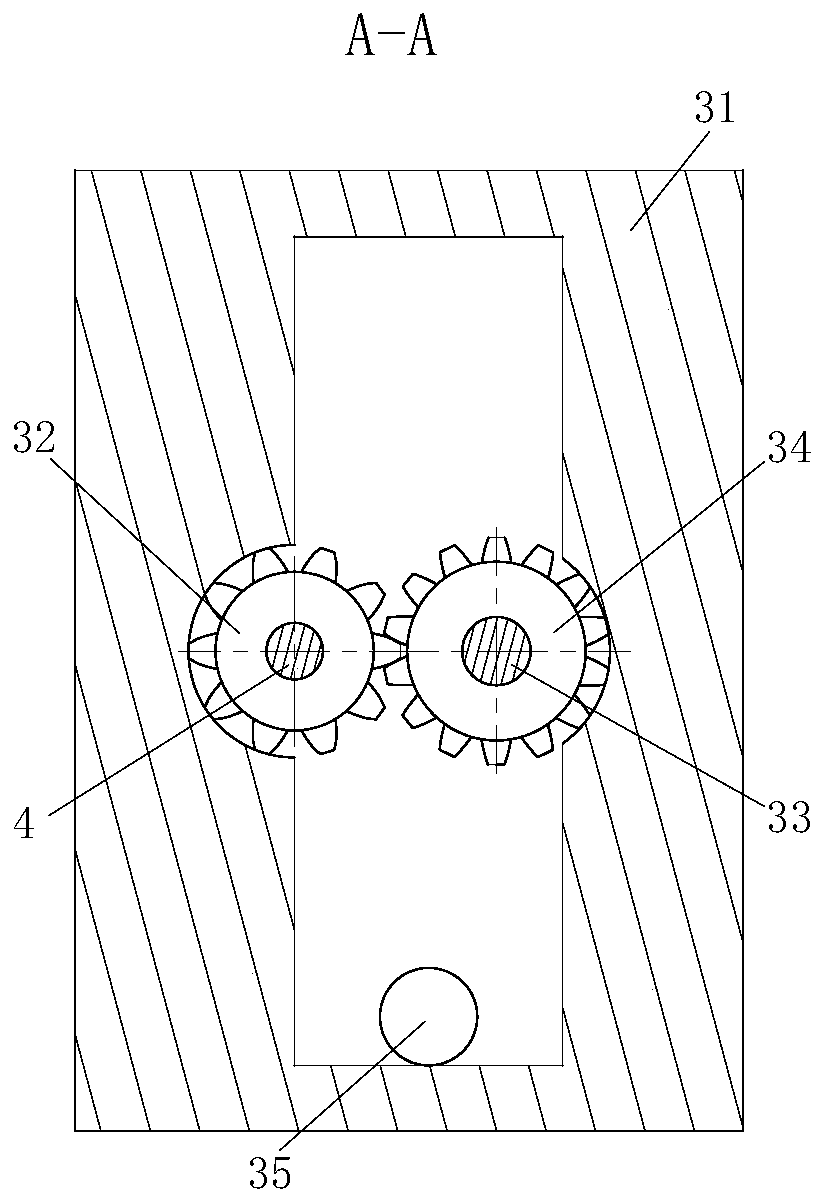

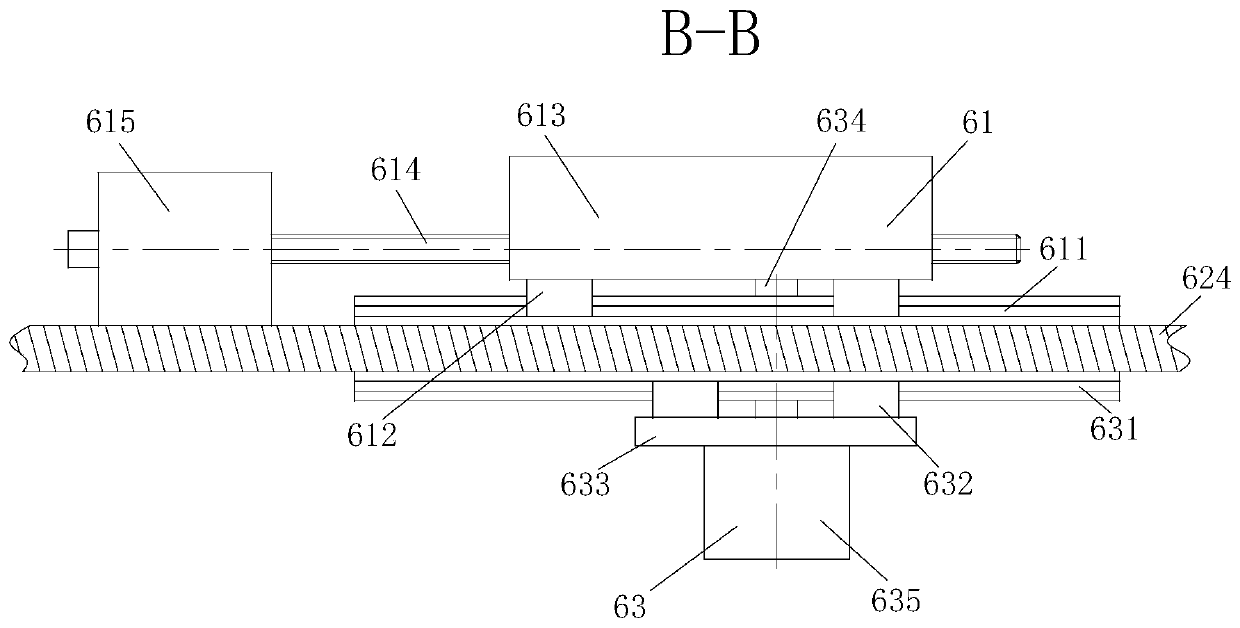

[0030] use Figure 1-Figure 9 The structure of an optical glass mirror polishing device according to an embodiment of the present invention will be described as follows.

[0031] Such as figure 1 , Figure 5 and Figure 6 As shown, a kind of optical glass mirror grinding equipment according to the present invention includes a base 1, a motor 2, a spray module 3, a connecting shaft 4, a fixing seat 5, a position adjustment module 6, a motor 2 7, and a connecting seat 8 and the grinding head 9; the motor one 2 is fixed on the base 1, and the motor one 2 is located at the right end of the base 1; the spray module 3 is fixed on the base 1, and the spray module 3 is located on the base 1 On the right side, the spray module 3 is used to cool the optical glass during processing, and the spray module 3 can also remove the debris on the optical glass, eliminating the influence of glass debris; the left end of the connecting shaft 4 Pass through the spray module 3 and fix on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com