Online printing system for injection-molded disposable tableware box covers

A printing system, a one-time technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problems of low secondary processing efficiency, large investment in molds, large waste, etc., to meet individual needs, save huge costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

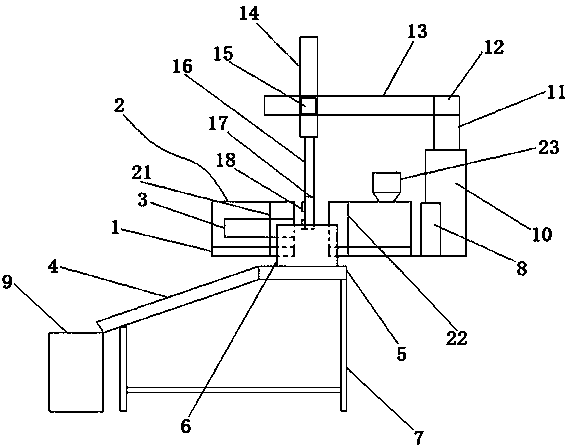

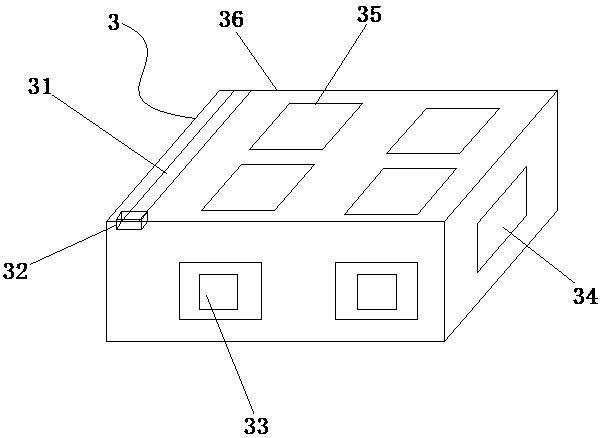

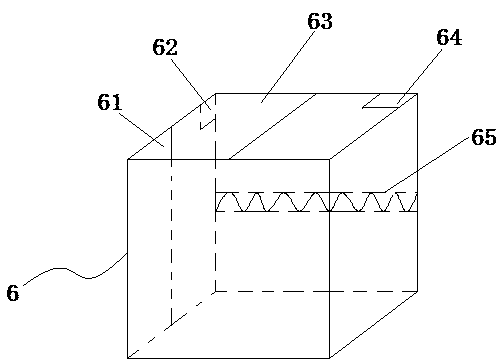

[0024] An online printing system for injection-molding disposable tableware box covers, including an injection molding machine 2, an ink supply system 3, a transmission device 4, and a drying box 6. The injection molding machine 2 includes an injection molding motor plate 21, an injection molding machine fixed plate 22, and an injection molding motor plate One side of 21 is fixed with ink supply system 3, and ink supply system 3 comprises housing 36, and the upper end surface of housing 36 is provided with ink cartridge 35, and the upper end surface of housing 36 is provided with scraper 31 that can move in parallel, scraper 31 One end of the housing 36 is provided with a servo drive device 32, the front of the housing 36 is provided with a pneumatic device 33 for pushing ink, and one side of the housing 36 is provided with a control panel 34;

[0025] A control box 8 is provided behind the fixed plate 22 of the injection molding machine, a base 10 is provided behind the contro...

Embodiment 2

[0035] An online printing system for injection molding disposable tableware box lids, comprising an injection molding machine 2, an ink supply system 3, a conveying device 4, and a drying box 6. The injection molding machine 2 includes an injection molding motor plate 21, an injection molding machine fixed plate 22, and an injection molding machine fixed plate The top of the shell of the plate 22 is provided with a feed port 23, the material is put into the feed port 23, the injection molding motor plate 21 moves to the fixed plate 22 of the injection molding machine, and the injection molding cover is completed, and the cover is stuck on the inner side of the injection molding motor plate 21. On the punch, the injection molding motor plate 21 moves away from the injection molding machine fixed plate 22, and the mechanical arm 16 moves downward, thereby driving the gripper 17 to move downward to between the molding motor plate 21 and the injection molding machine fixed plate 22....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com