Method for judging maintenance and servicing requirement of elevator based on elevator tracks

A technology for elevators and maintenance, applied in elevators, transportation and packaging, etc., can solve problems such as inconvenient inquiries, inability to guarantee, hidden dangers, etc., to improve work efficiency and reliability of maintenance, improve safety and reliability, and improve maintenance The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

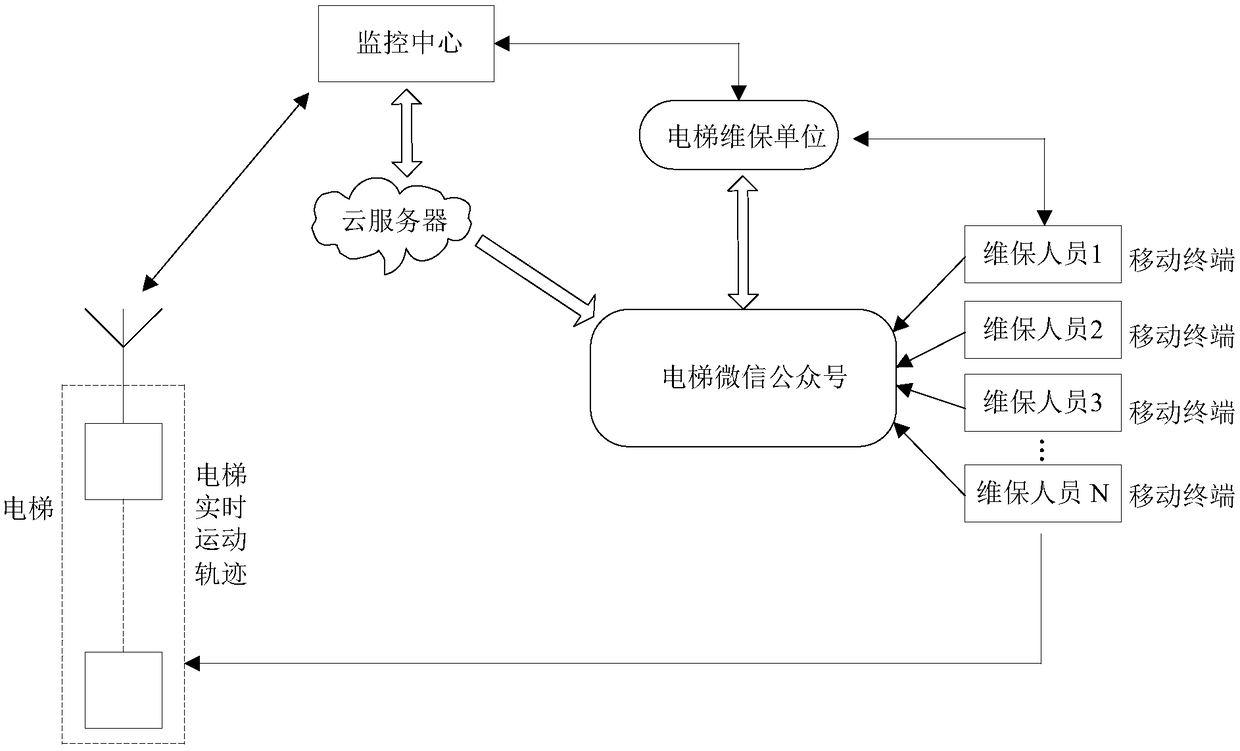

[0022] Such as figure 1 As shown, according to one aspect of the present invention, a method for judging whether an elevator is maintained based on the elevator trajectory is provided, comprising the following steps:

[0023] Step S1: Monitor the real-time movement track of the elevator car in real time and upload it to the monitoring center, call the elevator information list of the monitoring center to view the real-time movement track data of the elevator car,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com