A kind of preparation method of β-feooh nanocapsule

A technology of nanocapsules and nanorods, which is applied in the field of preparation of β-FeOOH nanocapsules, which can solve the problems of complex process and high production cost of iron oxide nanocapsules, and achieve the effects of excellent visible light absorption performance, simple operation and large product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

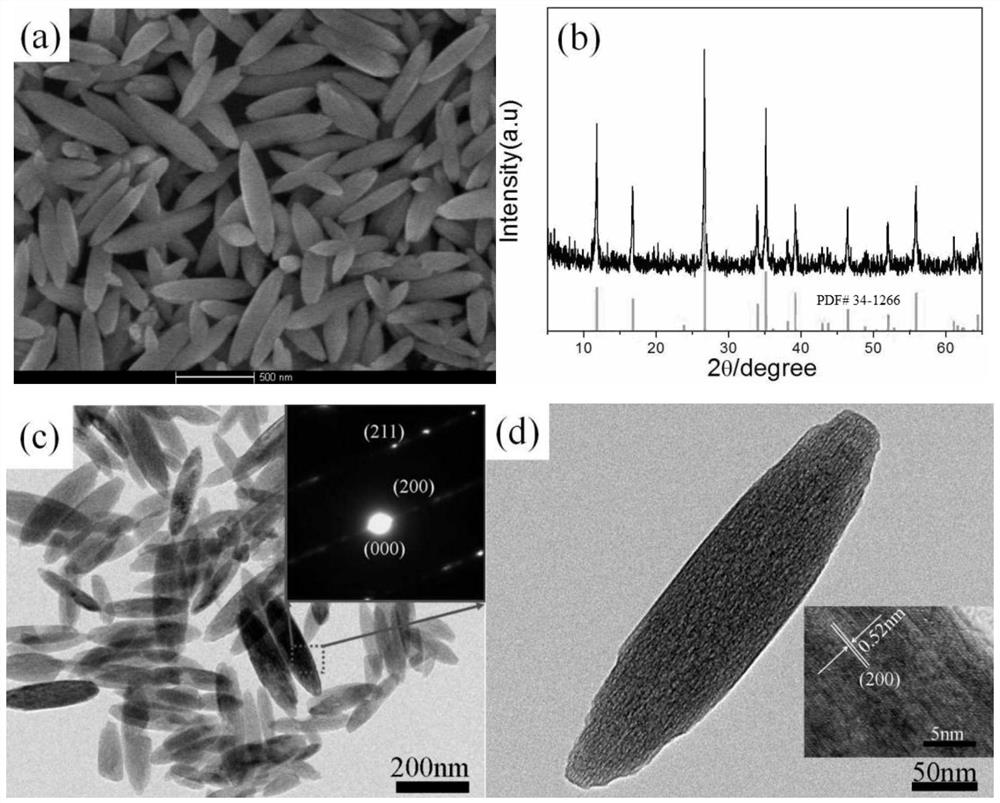

[0016] Example 1: Preparation and characterization of spindle-shaped β-FeOOH nanorods

[0017] Weigh 0.5g of FeCl 3 .6H 2 O was dissolved in 100 mL of deionized water to prepare an aqueous solution of ferric chloride, which was slowly heated to 95 °C, and β-FeOOH nanorods were obtained after a hydrolysis reaction for 72 h.

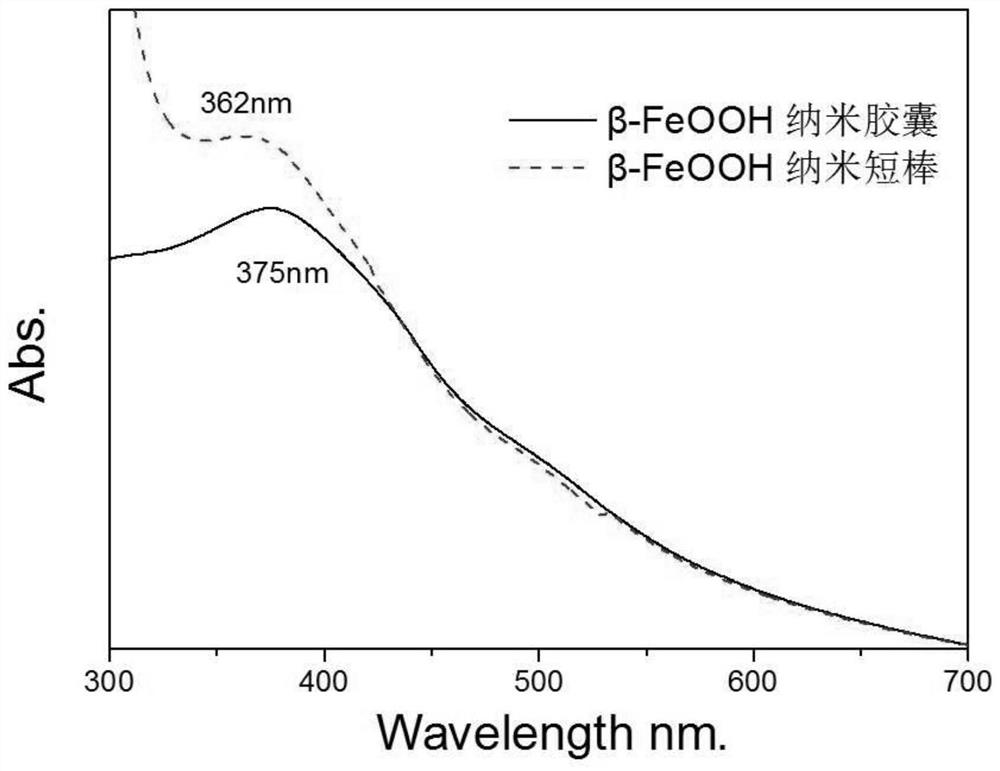

[0018] Using SEM and TEM to study the morphology and structure of the product respectively, it can be seen that the product morphology obtained is spindle-shaped (see figure 1 a and figure 1 c), combined with product XRD analysis, it can be known (see figure 1 b), the product is β-FeOOH (XRD standard spectrum: PDF#34-1266), and the visible-ultraviolet absorption maximum wavelength of the product is about 362nm (see image 3 dotted line).

[0019] The formation of β-FeOOH can be regarded as going through the following two processes: first, Fe 3+ Hydrolysis occurs to produce metastable Fe(OH) 3 colloid; then, Fe(OH) 3 Dehydration forms β-FeOOH, and t...

Embodiment 2

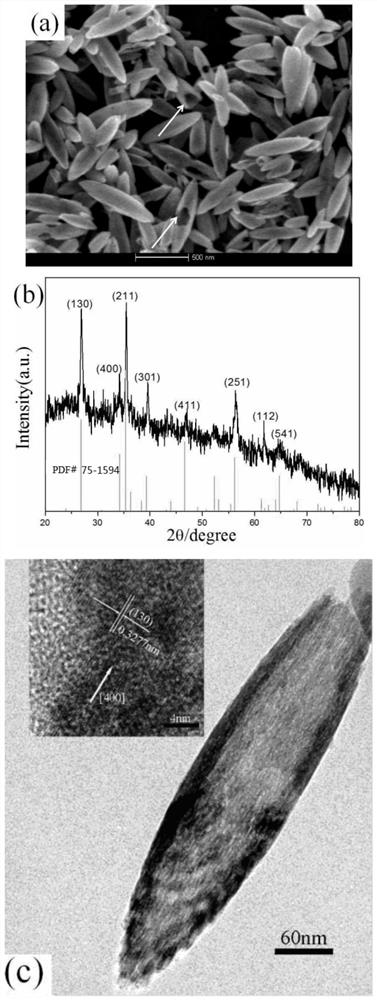

[0023] Embodiment 2: Preparation and characterization of β-FeOOH nanocapsules

[0024] Transfer 1 g of β-FeOOH nanorods into a reaction kettle, add 20 mL of glycerol and 2 mL of water, heat up to 180° C. and react for 12 hours to obtain β-FeOOH nanocapsules.

[0025] First, the morphology and structure of the obtained product were analyzed by SEM and TEM, respectively. It can be seen that the shape of β-FeOOH nanorods remained basically unchanged after alcohol heat treatment, and was still in the shape of a spindle (see figure 2 a), while TEM observations show that the solid β-FeOOH nanorods have transformed into hollow nanocapsules (see figure 2 c). XRD analysis result confirms further (see figure 2 b), When β-FeOOH nanorods transform into β-FeOOH nanocapsules, an allotropic transformation occurs. Compared figure 1 d and figure 2 It can be seen from c that after the β-FeOOH nanorods (10.53×10.53×3.03) are transformed into β-FeOOH nanocapsules (10.48×10.48×3.023), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com