Novel microbubble ozone reaction device

A reaction device and micro-bubble technology, which is applied in oxidation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of short filling life cycle, high ozone tower design, and limited installation conditions. problems, to achieve the effect of low replacement and maintenance frequency, low equipment height, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

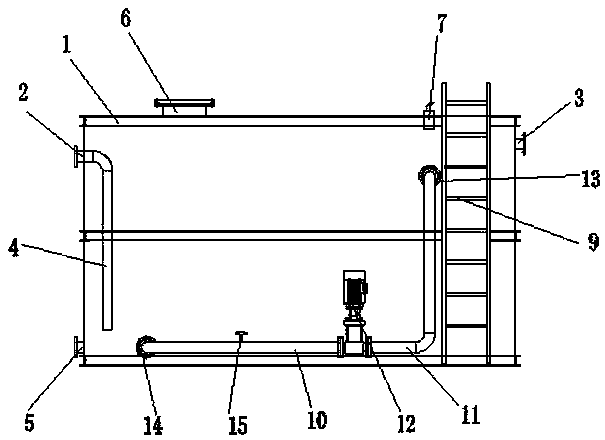

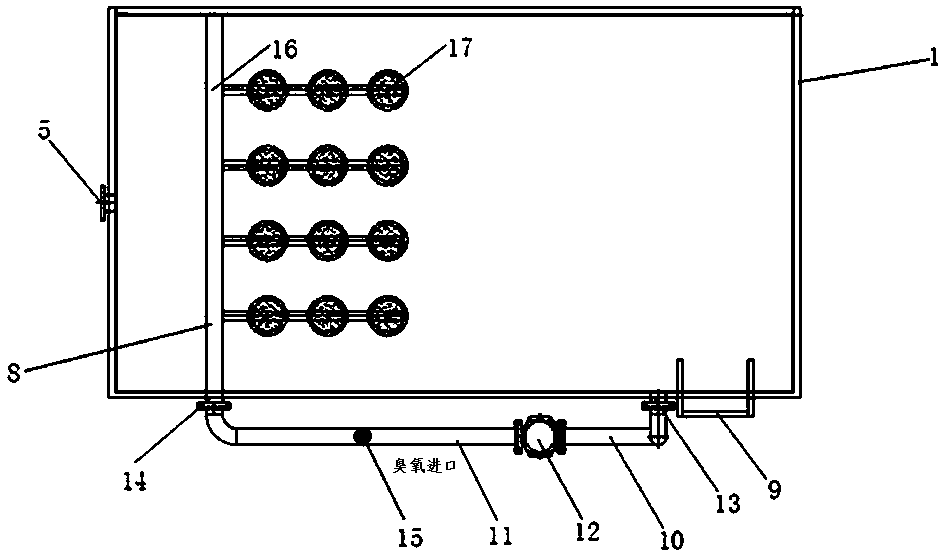

[0021] Embodiment 1: as figure 1 As shown, a novel micro-bubble ozone reaction device includes a box 1 in the shape of a cuboid, the box 1 is made of stainless steel, and the box 1 is provided with a water inlet 2 and a water outlet 3, and the water inlet 2 and the water outlet 3 are respectively Set on the upper wall at both ends of the box body 1, the water inlet 2 is provided with a water inlet pipe 4 leading to the bottom of the box body 1; the lower wall of the box body 1 is provided with a vent 5; the top of the box body 1 is provided with a manhole 6 and the breathing port 7; the outside of the box body 1 is provided with a ladder 9, and the outside of the box body 1 is also provided with an external circulation device 10. The external circulation equipment 10 includes a circulation pipeline 11 and a circulation pump 12. The circulation pipeline 11 is made of stainless steel, and the circulation pump 12 is set On the circulation pipeline 11 and fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com