A wear-resistant, non-slip, high-life and environmentally friendly plastic runway and its preparation method

A technology of plastic runway and longevity, applied in the field of pavement materials for sports fields, can solve the problems of difficult control of the hardness and friction coefficient of the runway, poor flatness of the finished surface, injury to students, etc., and achieves high anti-slip and deformation control effects and stable internal structure. , the effect of stable cooling gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

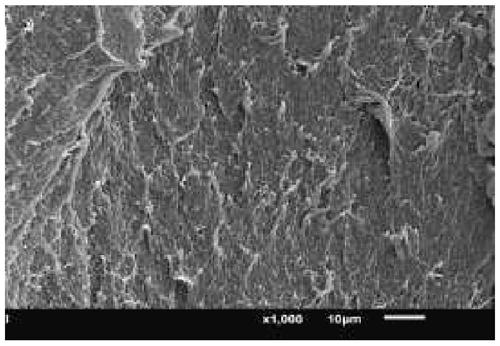

Image

Examples

Embodiment 1

[0027] A wear-resistant, non-slip, long-life and environment-friendly plastic runway, calculated in parts by weight: 55 parts of PVC paste resin, 35 parts of dioctyl phthalate, 3 parts of calcium zinc stabilizer, 5 parts of azodicarbonamide , 5 parts of anti-skid additives, 5 parts of aging inhibitor.

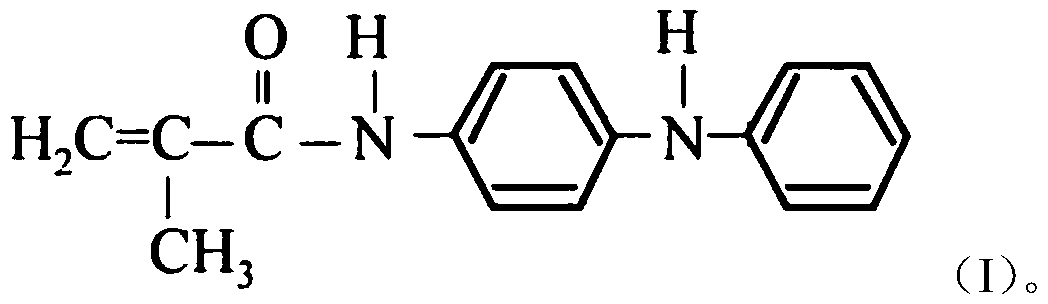

[0028] Wherein, the anti-skid additive is modified nano-calcium carbonate, and the preparation process of the modified nano-calcium carbonate is as follows: first dry the nano-calcium carbonate for 3 hours, and simultaneously raise the temperature of the high-speed mixer to 60°C, Then start stirring after nano-calcium carbonate is poured into high-speed mixer, add modifier, discharge after stirring; The weight ratio of described nano-calcium carbonate and modifier is 1:2, and described modifier is polyvinylpyrrolidone , triammonium citrate, and alkylphenol polyoxyethylene ether in a weight ratio of 1:1:2.

[0029] Wherein, the aging inhibitor is a mixture of 2,6-di-tert-butyl-...

Embodiment 2

[0039] A wear-resistant, non-slip, long-life and environmentally friendly plastic runway, calculated by weight of the composition, includes: 60 parts of PVC paste resin, 40 parts of dioctyl phthalate, 7 parts of calcium zinc stabilizer, and 7 parts of azodicarbonamide , 10 parts of anti-skid additives, 10 parts of aging inhibitor.

[0040] Wherein, the anti-skid additive is modified nano-calcium carbonate, and the preparation process of the modified nano-calcium carbonate is as follows: first dry the nano-calcium carbonate for 5 hours, and simultaneously raise the temperature of the high-speed mixer to 80°C, Then start stirring after nano-calcium carbonate is poured into high-speed mixer, add modifier, discharge after stirring; The weight ratio of described nano-calcium carbonate and modifier is 1:2, and described modifier is polyvinylpyrrolidone , triammonium citrate, and alkylphenol polyoxyethylene ether in a weight ratio of 1:1:2.

[0041] Wherein, the aging inhibitor is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com