Manufacturing method and construction method of plate with anti-corrosion and anti-skid additional layer

A production method and an additional layer technology, applied in the field of anti-slip stairs, can solve the problems of easy corrosion of steel plates, difficulty in achieving anti-slip effects, and easy falling off, and achieve the effects of reducing aesthetics, increasing aesthetics, and protecting social natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The step platform in this embodiment can be made of various materials such as steel plate, aluminum, concrete, etc. Therefore, the anti-corrosion and anti-skid plate produced by this production method can be correspondingly installed on the step platform of the above-mentioned materials. This embodiment only takes the step platform made of steel plate as an example. In other embodiments, it is also possible to implement a corresponding anti-corrosion and anti-skid plate installation method according to on-site adjustments according to on-site conditions.

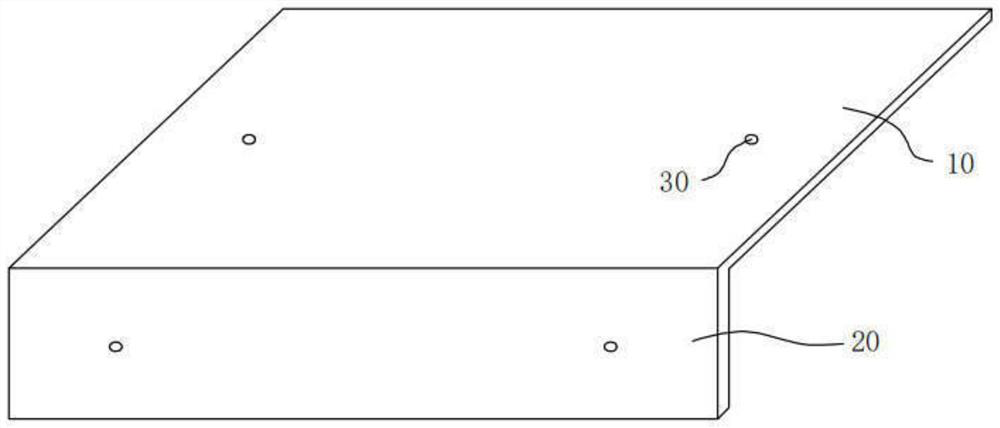

[0034] Such as figure 1 As shown, this embodiment proposes a method for manufacturing a plate with an anti-corrosion and anti-skid additional layer, including the following steps:

[0035] In the first technical solution, a method of manufacturing a plate with an anti-corrosion and anti-slip additional layer, which is suitable for covering the steel plate, aluminum plate, cement foundation surface and glass fiber rein...

Embodiment 2

[0055] This embodiment proposes an installation method for a plate with an anti-corrosion and anti-skid additional layer, which is used to install the anti-corrosion and anti-skid plate made by the method of manufacturing a plate with an anti-corrosion and anti-skid additional layer as described in Embodiment 1, including the following steps,

[0056] The connection hole 30 on the liner is aligned with the step surface and the front flanged steel plate 20, and the step surface and the front flanged steel plate 20 are drilled; Spread 5MM glue on the surface of the folded steel plate 20, and fill up the concave surface of the step surface; lift the liner step to the corresponding step of the corresponding step, and flatten it; screw the screw into the screw hole; check the flatness, If unevenness is found, adjust it in time; close the steps; remove the glue in the seams on both sides of the steps to expose the base surface to ensure that the polyurea joint agent adheres to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com