Dyeing and finishing process for cotton-plaited polyester one-way wet-permeable knitted fabric

A technology of knitted fabrics and polyester-covered cotton, which is applied in the field of dyeing and finishing of knitted fabrics, can solve the problems of slow drying speed and long drying time, and achieve the effects of saving energy, avoiding color stains, and improving dyeing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

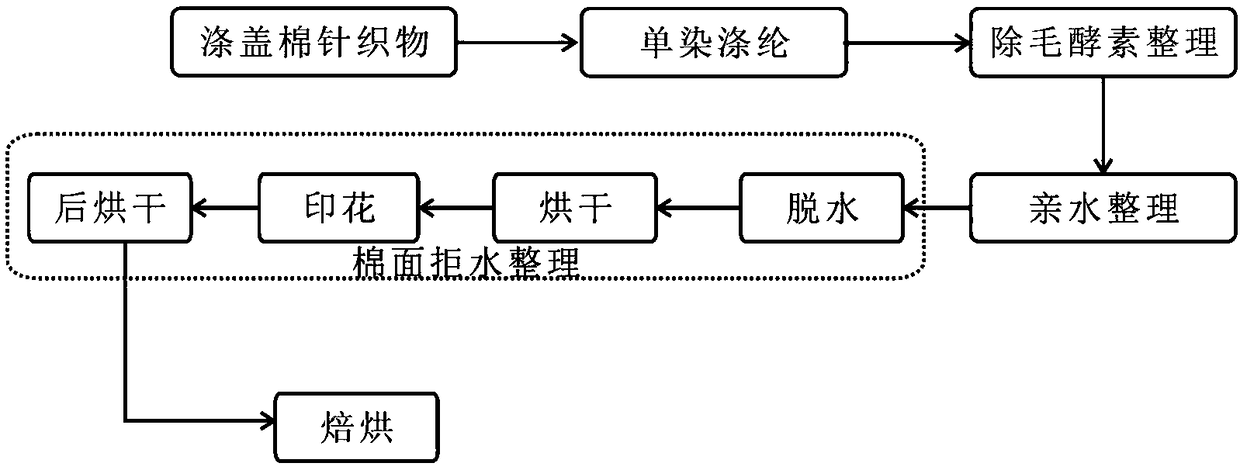

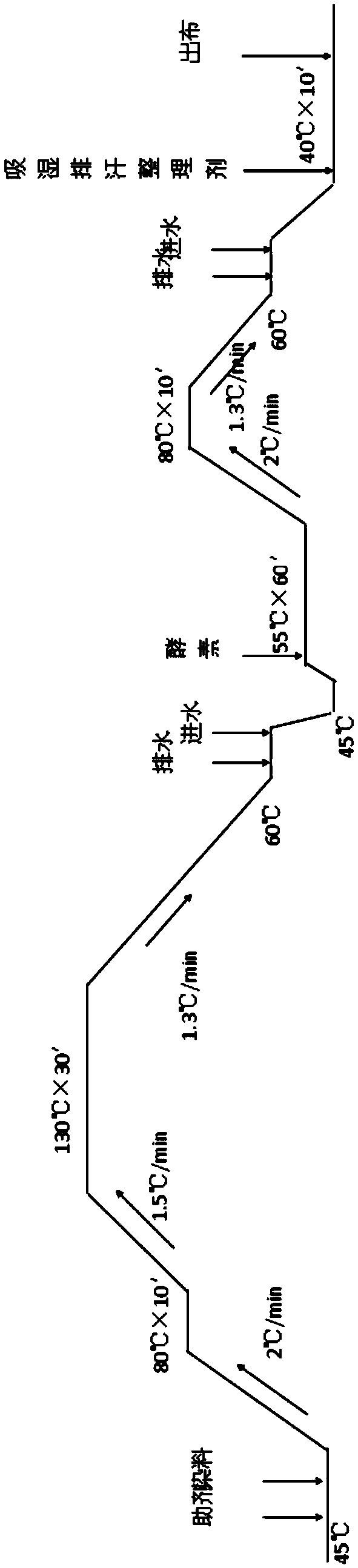

[0037] Such as figure 1 , 3 As shown, this embodiment provides a dyeing and finishing process for polyester-covered cotton unidirectional moisture-wicking knitted fabrics. The specific process flow is: weaving fabric→single-dyed polyester→hair removal enzyme finishing→hydrophilic finishing→cotton surface water-repellent finishing→ Baking, wherein the water-repellent finishing of the cotton face includes dehydration, drying, printing and post-drying in sequence of processes.

[0038] In this embodiment, the polyester face of the polyester-covered cotton knitted fabric is made of moisture-absorbing and sweat-wicking polyester, and the next-to-body cotton face is made of pure cotton yarn. W"-shaped fibers and other special-shaped cross-section fibers, because there are grooves on the surface of the special-shaped cross-section fibers, the longitudinal small gaps between the fibers increase, the capillary effect is enhanced, and the speed of sweat wetting is beneficial to increas...

Embodiment 2

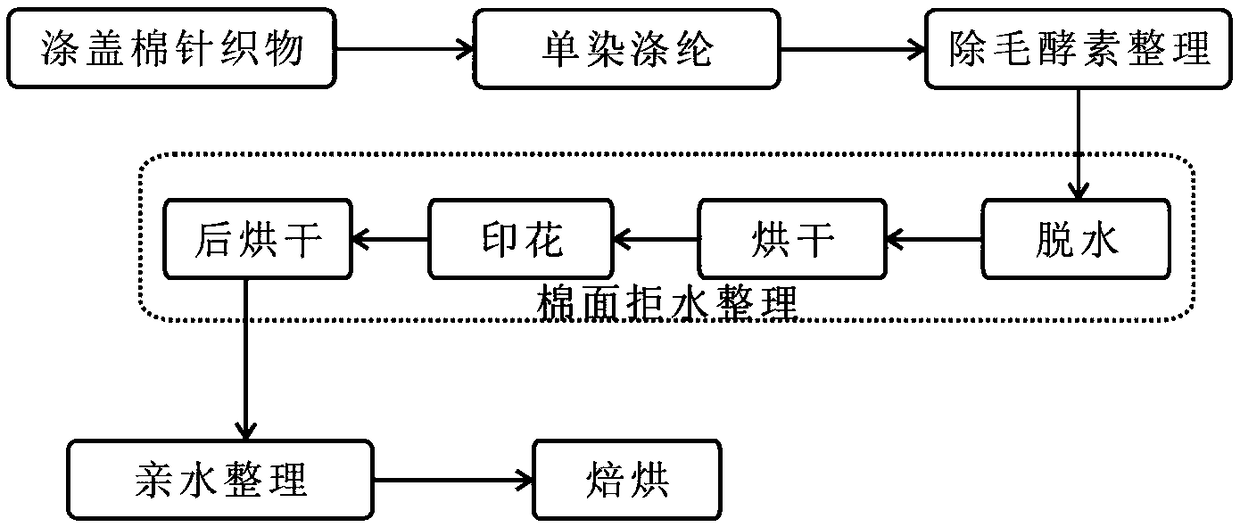

[0052] Such as figure 2 , 4 As shown, this embodiment provides a dyeing and finishing process for polyester-covered cotton unidirectional moisture-wicking knitted fabrics. The specific process flow is: weaving fabric→single-dyed polyester→hair removal enzyme finishing→cotton surface water-repellent finishing→hydrophilic finishing→ Baking, wherein the water-repellent finishing of the cotton face includes dehydration, drying, printing and post-drying in sequence of processes.

[0053] In this embodiment, the polyester face of the polyester-covered cotton knitted fabric is made of moisture-absorbing and sweat-wicking polyester, and the next-to-body cotton face is made of pure cotton yarn. W"-shaped fibers and other special-shaped cross-section fibers, because there are grooves on the surface of the special-shaped cross-section fibers, the longitudinal small gaps between the fibers increase, the capillary effect is enhanced, and the speed of sweat wetting is beneficial to increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com