Replaceable prefabricated shock-absorbing pier

A prefabricated and pier technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as slow development, difficult accurate quantitative analysis, damper failure, etc., and achieve the effect of improving earthquake resistance, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

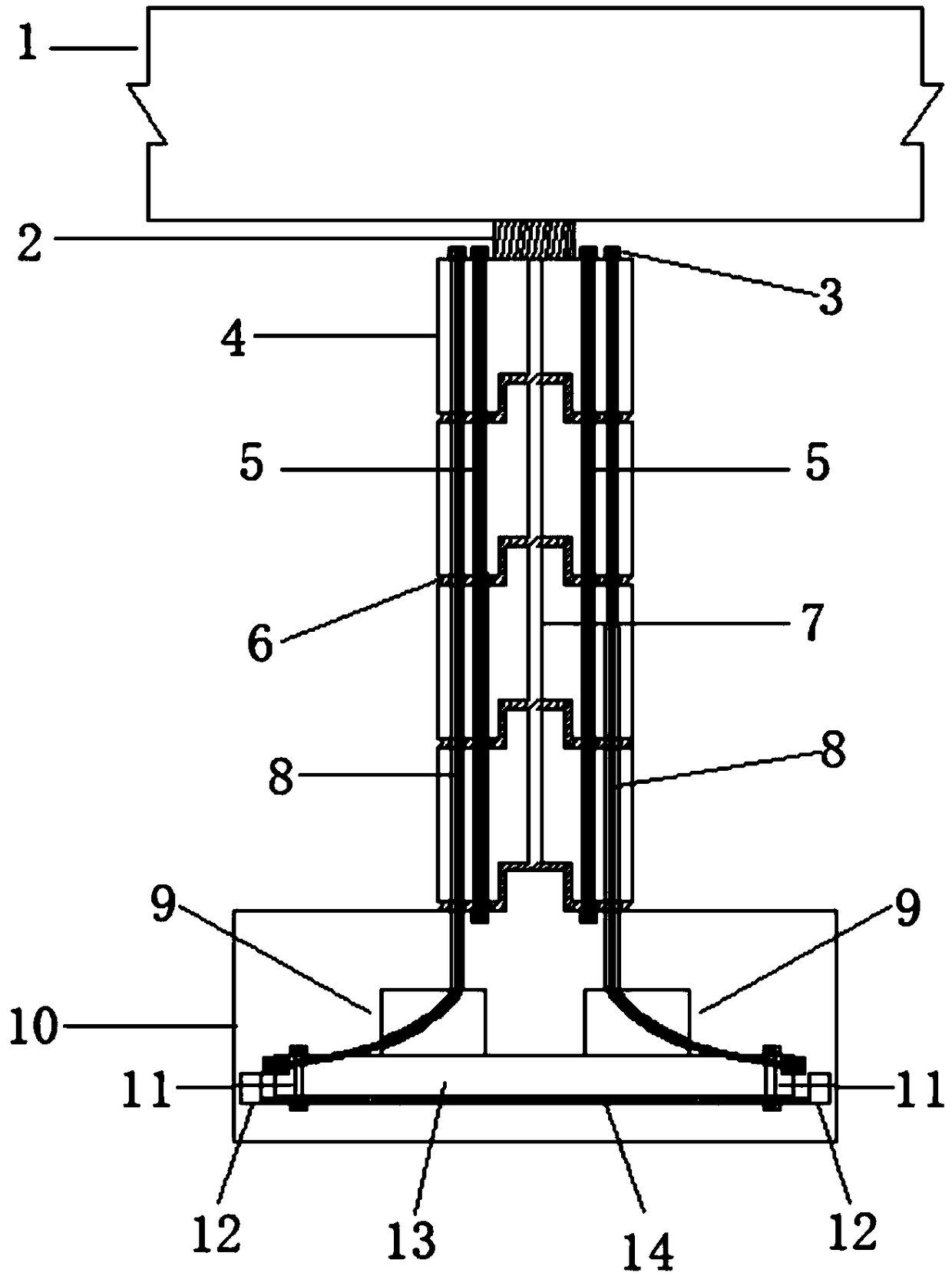

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

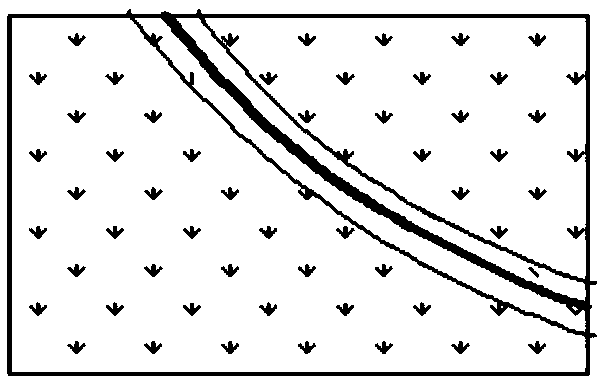

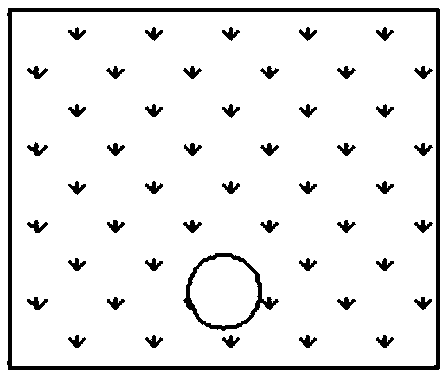

[0029] like Figure 1-4 As shown, a replaceable assembled shock-absorbing pier of the present invention includes a pier body and a cap 10 arranged at the lower part of the pier body, the top of the pier body supports the main girder 1 through a support 2, and the pier body consists of several assembled columns 4 are assembled up and down together, and each assembled column block 4 includes an upper protrusion and a groove at the bottom, and the protrusion of the lower assembled column block 4 is inserted into the groove of the upper assembled column block 4. Protrusions are provided, which are inserted into the grooves of the upper assembling column block 4 . The raised area of each assembled column block 4 accounts for 1 / 3 of the cross-sectional area of the assembled column block 4 . There are also wet joints 6 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com