Machine drilling end reaming drill bit special for filling pile, and construction method thereof

A cast-in-place pile and tip technology, which is applied to drill bits, sheet pile walls, drilling equipment, etc., can solve problems such as large gaps, uncertain sizes, and inability to adapt to the adjustment of reaming diameters, so as to reduce the possibility of damage and reduce The effect of cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

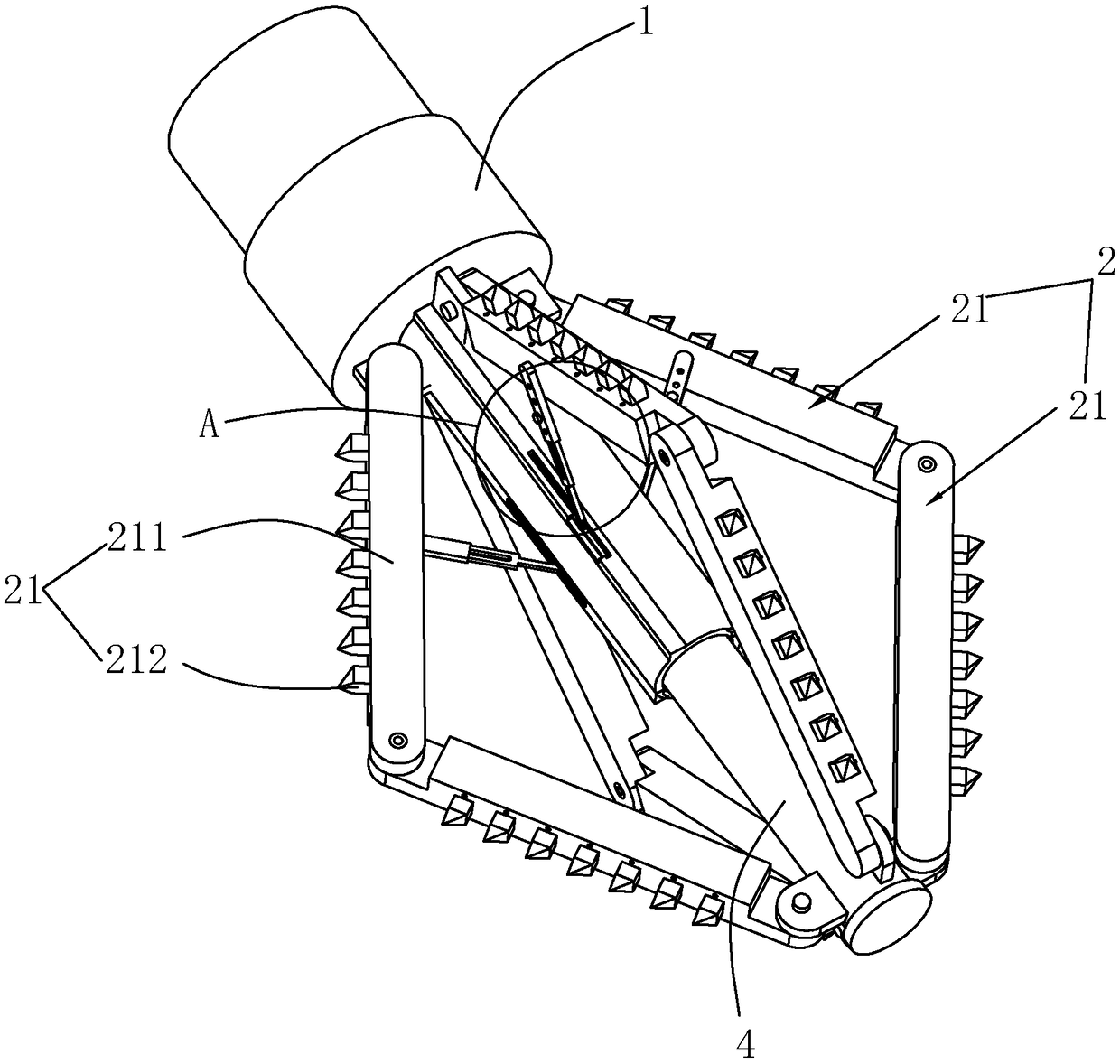

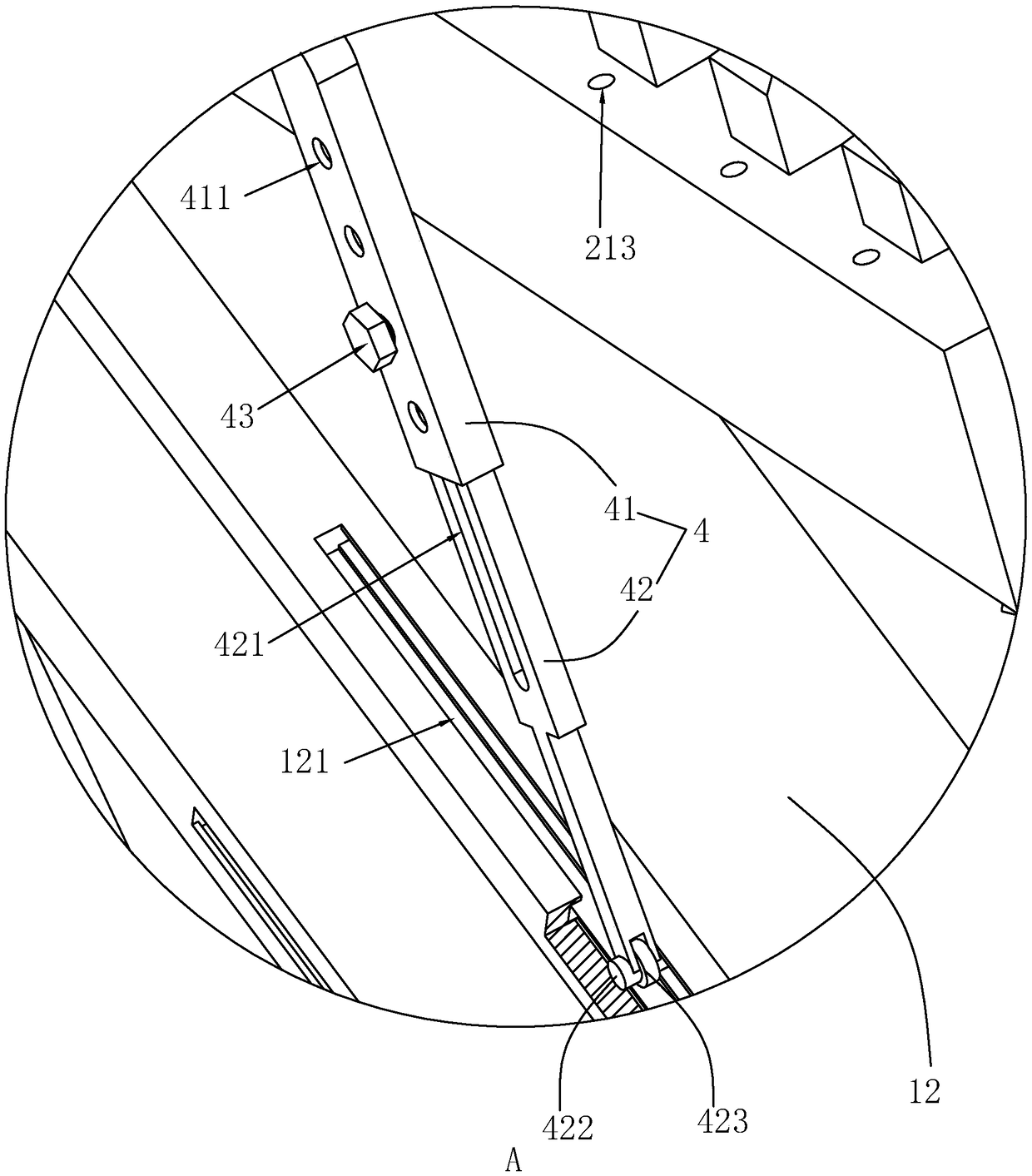

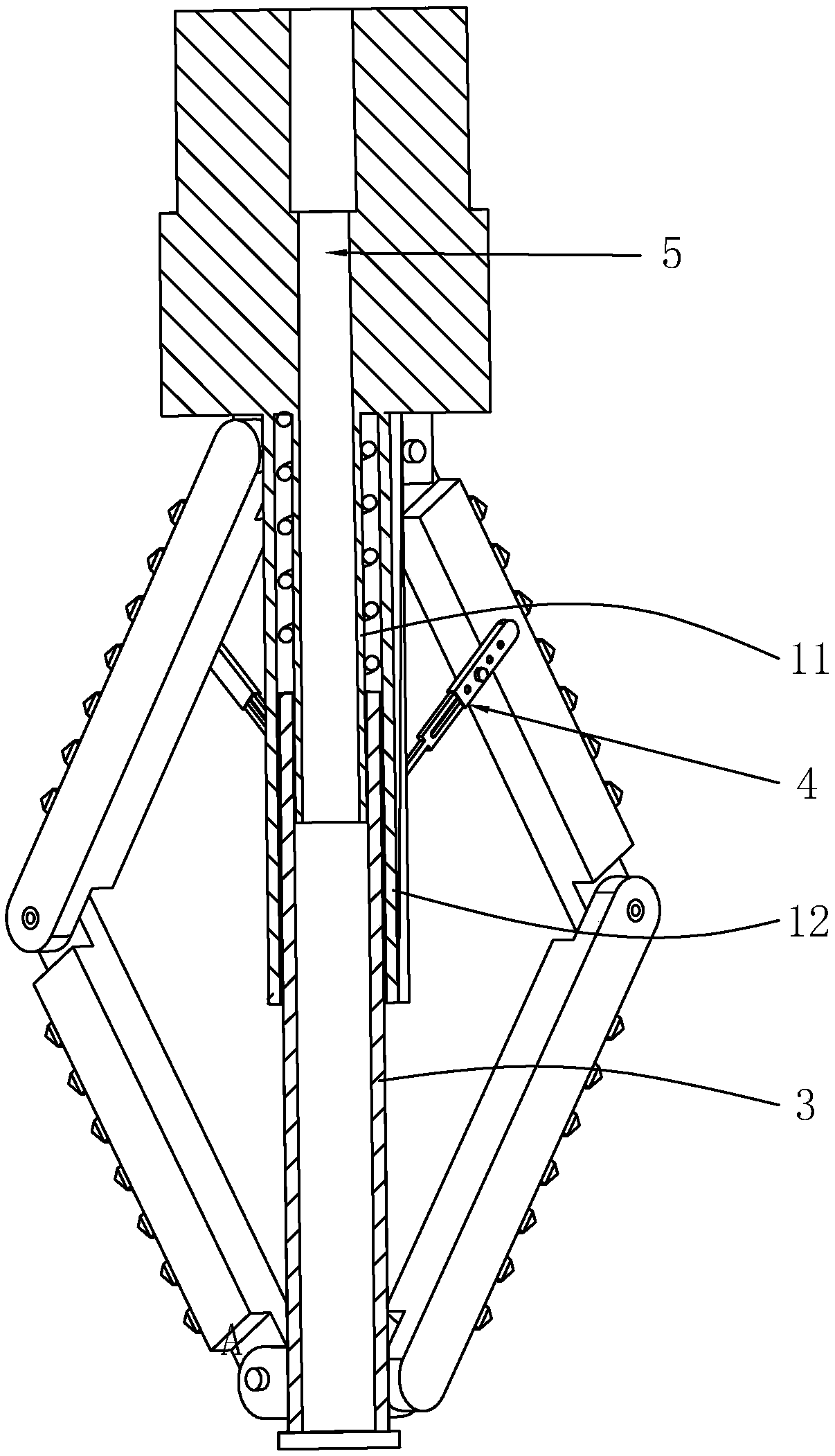

[0041] like figure 1 , 2 As shown, a special special drill bit for cast-in-situ pile reaming with machine drill ends, including a reducing joint 1 connected with a drill rod and a plurality of tool holders 2, and the number of tool holders 2 is set to four in this embodiment. The side wall of the variable diameter joint 1 away from the drill pipe is provided with an inner sleeve rod 11 and an outer sleeve rod 12, the outer sleeve rod 12 is sleeved outside the inner sleeve pipe, and a guide rod 3 is movable between the inner sleeve rod 11 and the outer sleeve rod 12 to guide A spring is connected to one end of the rod 3 between the inner sleeve rod 11 and the outer sleeve rod 12 , and the other end of the spring is connected to the reducing joint 1 .

[0042] like figure 1 , 2 As shown, one end of the tool holder 2 is hinged with the side wall of the inner sleeve rod 11 provided with the reducing joint 1, and the other end is hinged with the guide rod 3 and the hinge point i...

Embodiment 2

[0050] A construction method of a cast-in-place pile with a machine-drilled end reaming is carried out according to the following steps:

[0051] a) The operator uses a bulldozer to initially level the site, and then the operator positions the cast-in-place piles according to the construction drawings. After the positioning is completed, use the pile position counter to determine the position of the casing.

[0052] b) Put the side wall of the casing against the side wall of the pile position counterpointer. At this time, the point to be punched is at the center of the casing, and pressure is applied on the side wall of the casing away from the ground to make one end of the casing 50cm into the ground, the casing should be set vertically at this time, and the deviation should be corrected in time when the position of the casing is deviated; Drill holes at the predetermined points and construct to the predetermined reaming depth.

[0053] c) Manually excavate the mud pool near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com