Method for optimizing oil layer pressure plugging and displacement technical modes

A process and mode technology, applied in the field of oil layer plugging and flooding process mode selection, can solve problems such as inability to effectively tap the remaining oil in complex well groups, and achieve the effect of avoiding incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

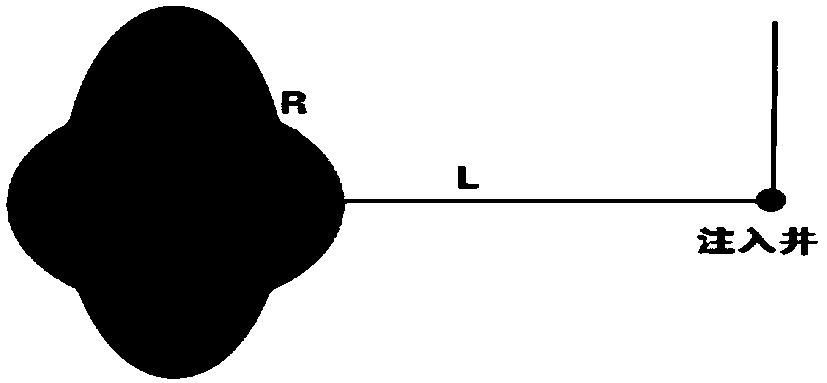

Image

Examples

Embodiment 1

[0071] The experimental well is well B1-6-P68 in the Changyuan I oil layer of Daqing.

[0072] Well B1-6-P68 is an old production well after polymer flooding, and it was drilled on October 10, 1996. The oil-water well spacing of this well is 175m, the well depth is 1166.71m, and the perforated section depth is 1068.9-1097.7m. A total of 8 sublayers from PI1 to PI7 are perforated, including PI2 sublayer.

[0073] (1) Target well group data preparation

[0074] Well Group Reservoir Development

[0075] The target well group is located at the edge of the horizontal well group experiment area, with an oil well in the middle and 6 injection wells around it. The mining target layer of this well belongs to the river-delta sedimentary system, and the PI2 unit belongs to the high-bending large-scale compound meandering river sediment of the floodplain facies, and the reservoir point bar sand body is well developed.

[0076] It can be seen from the detailed description of the sand ...

Embodiment 2

[0089] The experimental well is the L9-PS2133 well in the Changyuan I oil layer in Daqing.

[0090] Well L9-PS2133 is an old production well after polymer flooding, and its drilling was completed on January 4, 2008. The oil-water well spacing of this well is 150m, the well depth is 1141.10m, and the perforation section depth is 1014.8~1035.2m, and a total of 5 sublayers from SIII3 to 10 are perforated, including SIII3-7 sublayers.

[0091] (1) Target well group data preparation

[0092] Well Group Reservoir Development

[0093] The target well group is located in Well L9-PS2133, which is located in the Northeast Block 1 of Lamadian Oilfield, with a block area of 7.1 km2, where SIII3-10 is exploited, and SIII3-7 layers are continuous channel sand bodies with good porosity and permeability conditions, belonging to a kind of reservoir.

[0094] It can be seen from the detailed description of the sand body development of the well group reservoirs that the SIII3-7 unit of We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com