A method for preparing molecularly imprinted sensors by photocatalytic raft polymerization and its application

A molecular imprinting and sensor technology, which is applied in the field of photocatalytic RAFT polymerization to prepare molecularly imprinted sensors, can solve the problems of complex reaction conditions and cumbersome processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

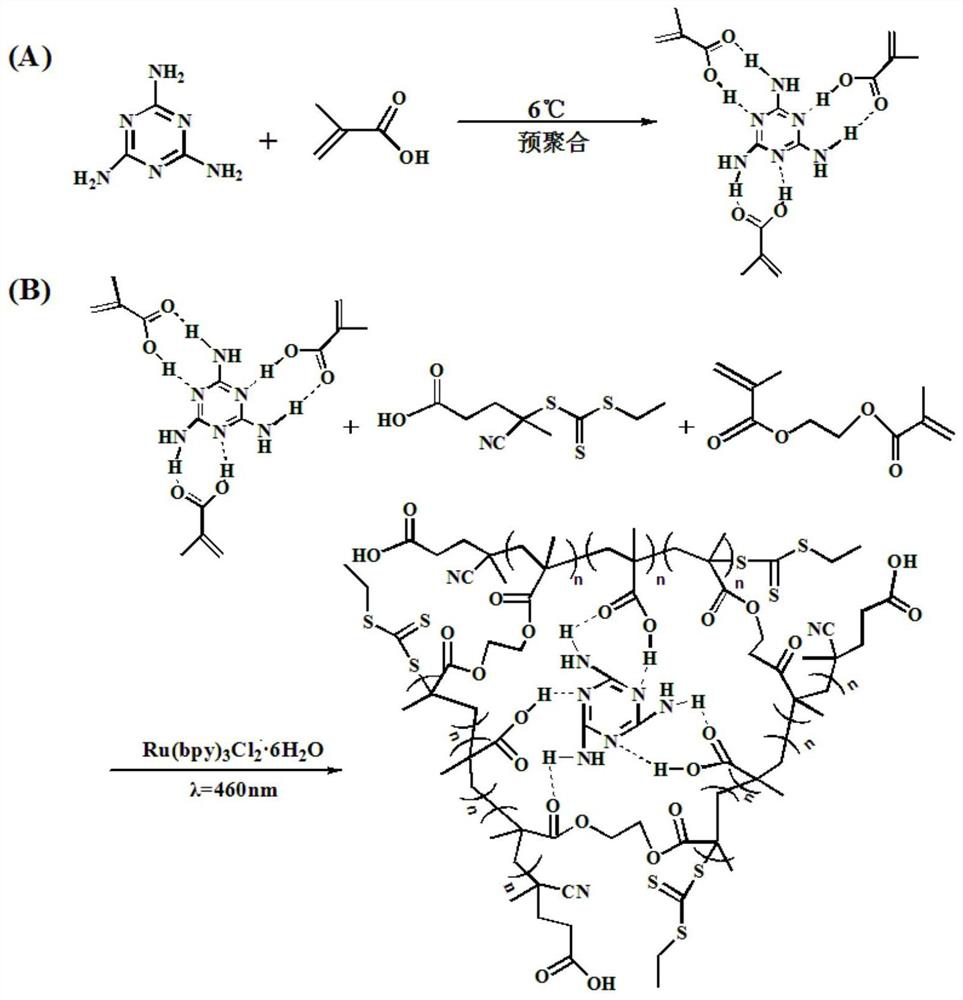

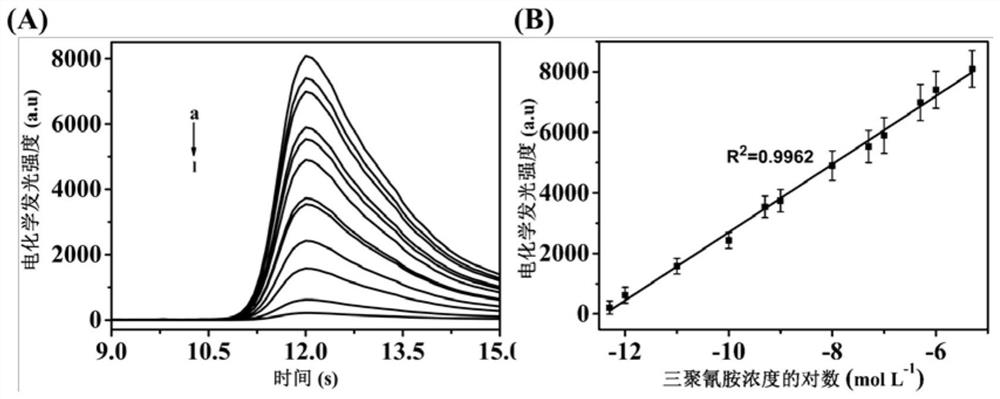

[0031] Embodiment 1: the method for preparing melamine molecularly imprinted sensor

[0032] 1. The synthesis process of melamine-methacrylic acid (MAA) prepolymerization solution

[0033](1) 0.014g ruthenium terpyridyl was added to 25 mL of an aqueous solution of gold nanoparticles with a concentration of 1 mg / mL, reacted at room temperature for 15 minutes, and gold nanoparticles immobilized with ruthenium terpyridyl were obtained at a speed of 8000 rpm.

[0034] (2) 6.30 mg of melamine was completely dissolved in 20 mL of a mixed solution of ethanol and water (4:1 by volume), and then ultrasonicated for 10 minutes.

[0035] (3) Add 17.22 mg of MAA solution to the solution obtained in step (2), and react at 6° C. for 6 hours to obtain a prepolymer solution.

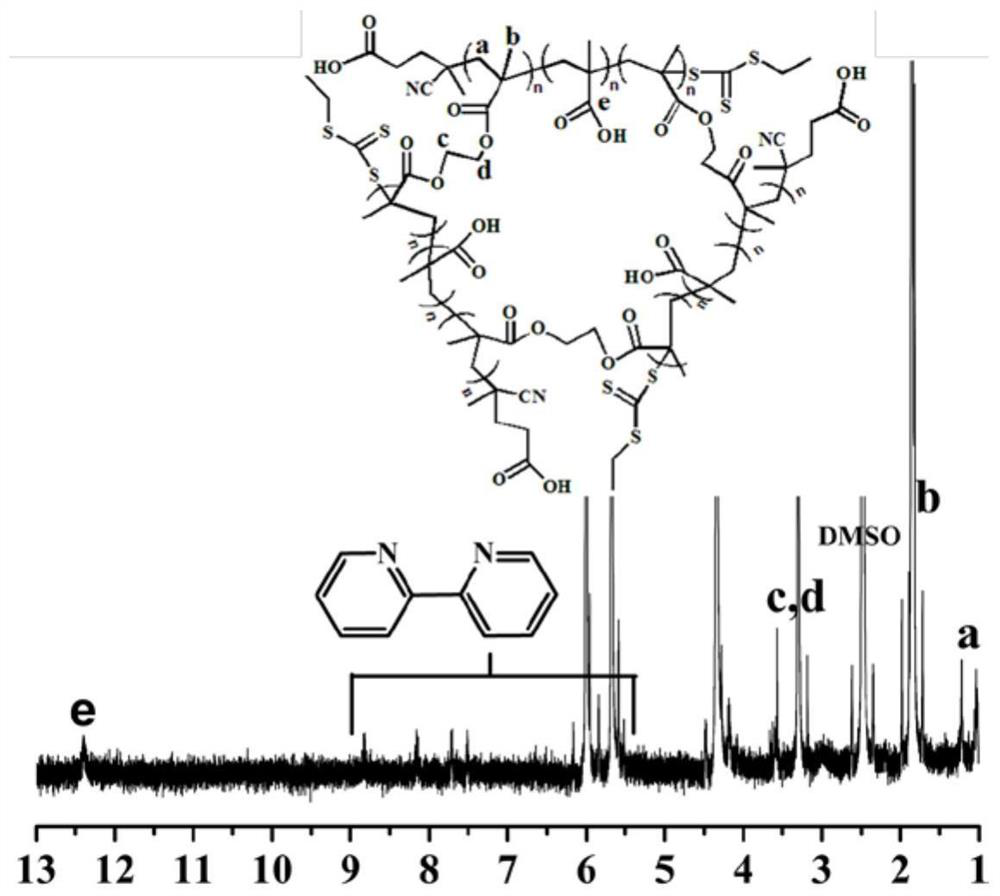

[0036] 2. Synthesis of cross-linked melamine-polymethacrylic acid (PMAA) polymer

[0037] (1) Add 0.198g of crosslinking agent ethylene glycol dimethacrylate and 0.26mg RAFT reagent (4-cyano-4-ethyl-trithiopentanoic ac...

Embodiment 2

[0045] Embodiment 2: the method for preparing melamine molecularly imprinted sensor

[0046] 1. The synthesis process of melamine-sodium p-styrenesulfonate prepolymerization liquid

[0047] (1) 0.045g ruthenium terpyridyl was added to 50mL of an aqueous solution of gold nanoparticles with a concentration of 12mg / mL, reacted at room temperature for 110 minutes, and obtained gold nanoparticles immobilized with ruthenium terpyridine at a speed of 5000 rpm.

[0048] (2) 8.50 mg of melamine was completely dissolved in 450 mL of a mixed solution of ethanol and water (4:1 by volume), and then ultrasonicated for 20 minutes.

[0049] (3) Add 25.03 mg of MAA solution to the solution obtained in step (2), and react at 12° C. for 10 hours to obtain a prepolymer solution.

[0050] 2. Synthesis of cross-linked melamine-polystyrene sodium polysulfonate polymer

[0051] (1) Add 0.312g of cross-linking agent orthosilicate ethyl ester and 1.55mg RAFT reagent (4-cyano-4-ethyl-trithiopentanoic ...

Embodiment 3

[0061] Example 3: A method for preparing a lincomycin molecularly imprinted sensor. The melamine in Example 1 was replaced by lincomycin. The other preparation methods were the same, and a sensor with excellent specific recognition ability for lincomycin was prepared. .

[0062] Using the same preparation method, using midecamycin, tropicamide, and erythromycin as template molecules, sensors with excellent specific recognition capabilities for midecamycin, tropicamide, and erythromycin were also prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com