Passive percussive material damage detecting device and method thereof

A material damage and detection device technology, which is applied to measuring devices, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. The effect of simplifying the overall structure, reliable detection results, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Before describing the embodiments of the present invention in detail, the principle of the present invention will be explained first with reference to the accompanying drawings.

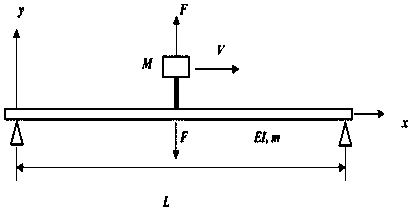

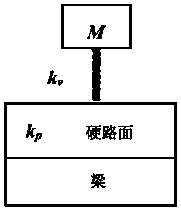

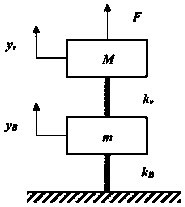

[0042] figure 1 It is a schematic diagram of the working principle of the passive percussion type material damage detection device according to the embodiment of the present invention. like figure 1As shown, it uses a simplified model to assist in understanding the theoretical basis of the passive percussion-type material damage detection scheme proposed by the embodiment of the present invention. Taking the material to be detected as a bridge as an example, in this model, the passive percussion type material damage detection device is modeled as having k V mass M on a spring of stiffness , and the bridge is also modeled as a two-dimensional simply supported beam of length L modeled as a planar Bernoulli-Eu Pull (Bernoulli-Euler) beams. Structural damage detection equipment moves across th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com