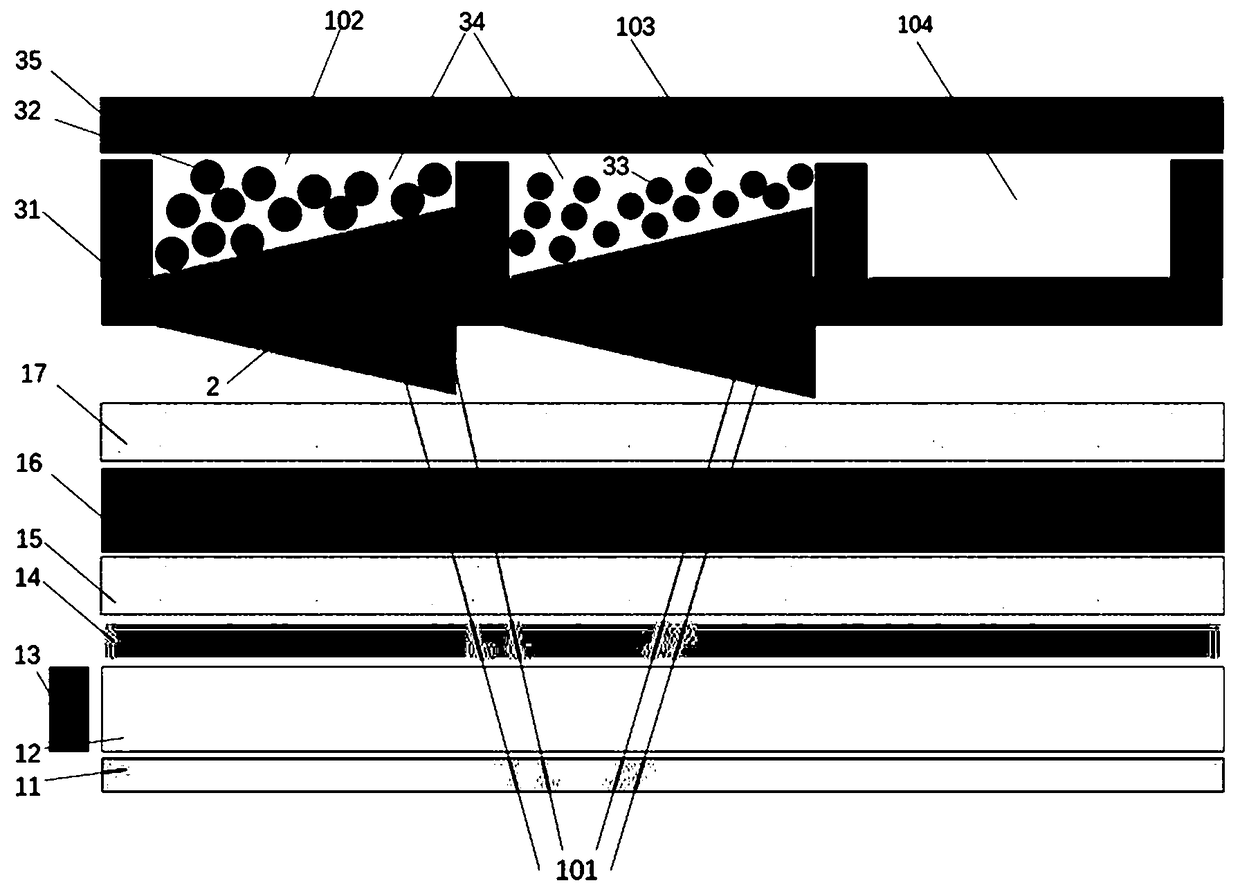

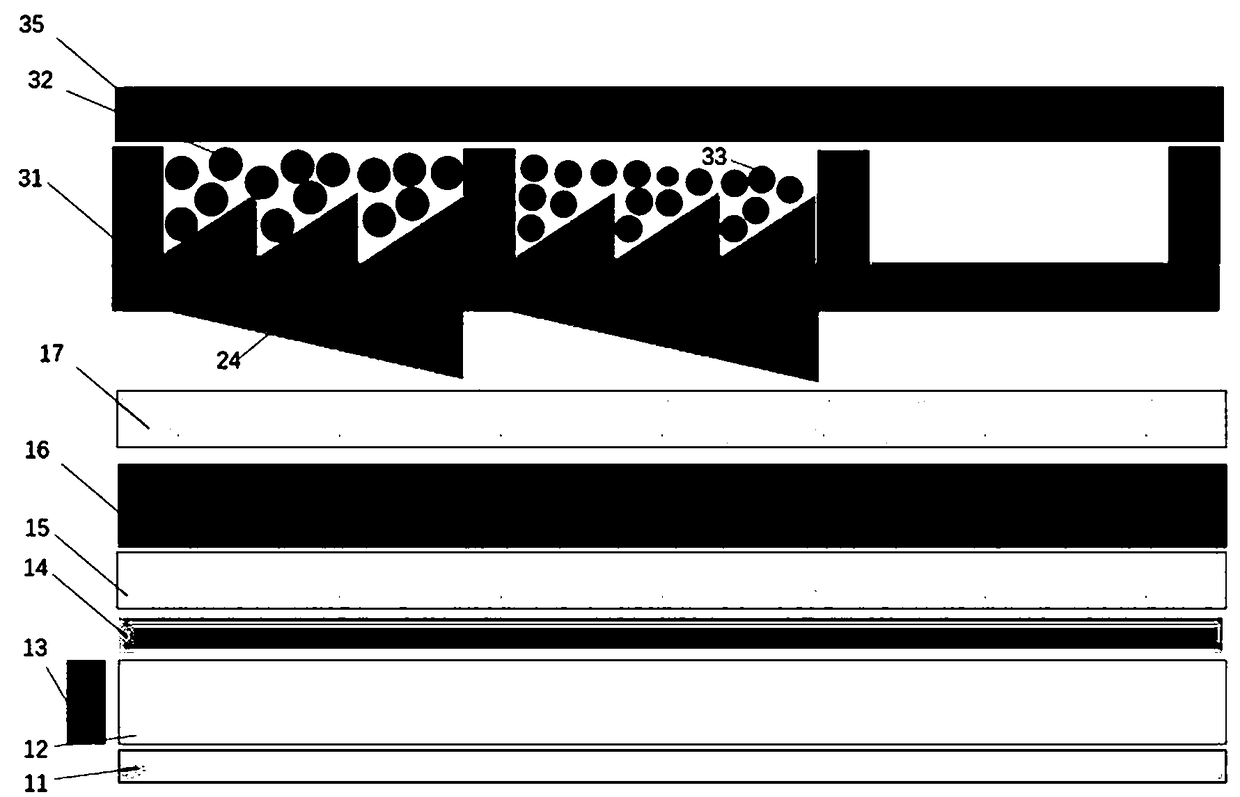

Quantum dot colored film structure of wedge-shaped substrate

A wedge-shaped substrate, quantum dot technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of insufficient color conversion rate, reduced color purity, uneven distribution of quantum dots, etc., to improve light utilization and reduce blue light strings. Color, enhance the effect of light purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

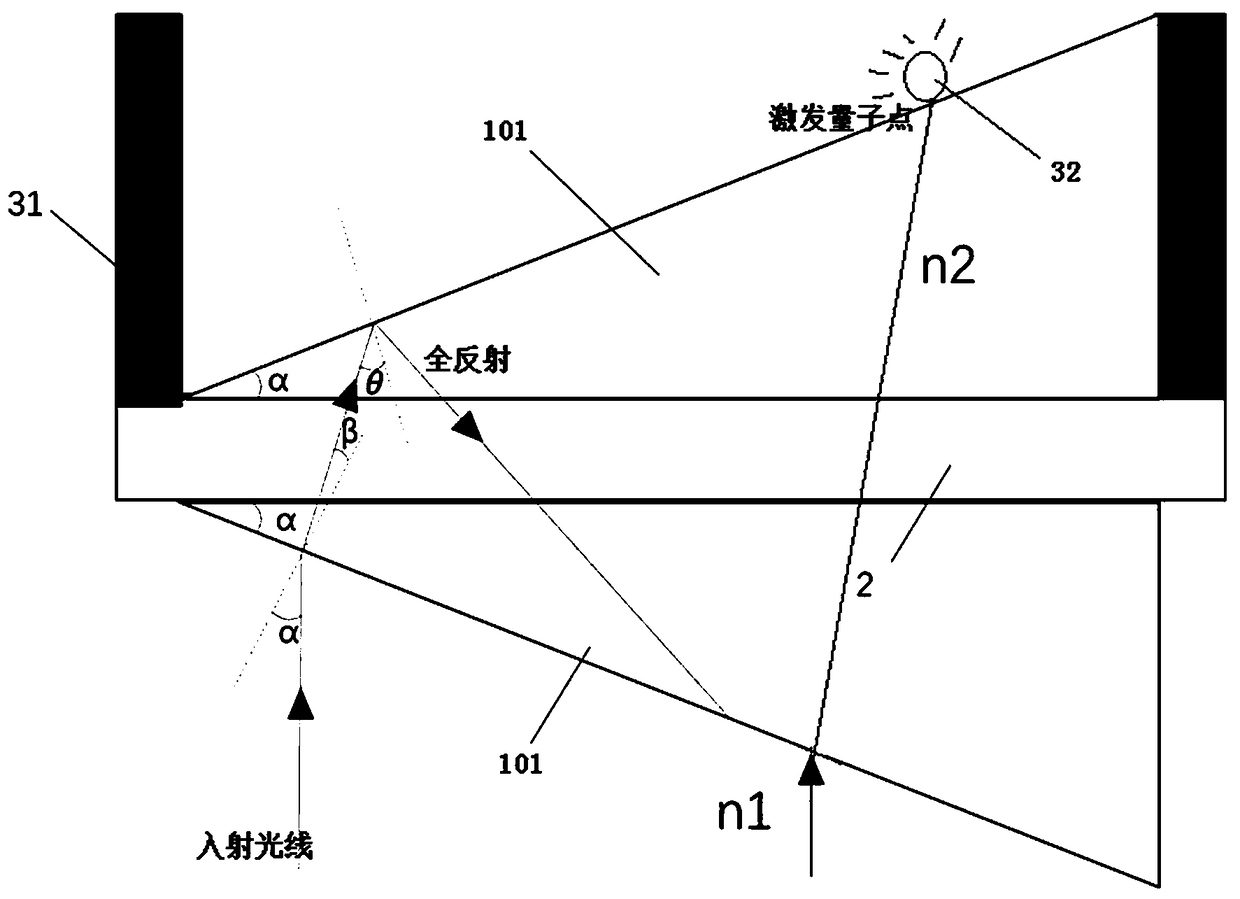

[0045]In this example, after the light is incident on the wedge-shaped microstructure 101 on the lower surface of the substrate 2, the bottom angle of the lower wedge-shaped microstructure 25 is set as α, when the light enters the wedge-shaped substrate with the refractive index n2 from the refractive index n1 vertically upward 2, the incident angle is also α, the refraction angle is β, and the angle with the upper wedge-shaped microstructure 24 on the upper surface of the substrate 2 is θ. From this, we can get the relationship formula between angle a and refractive index n1 and n2:

[0046]

[0047] Using PMMA as the wedge-shaped substrate 2 and the outside is air, then n1=1.49, n2=1. Bring n1 and n2 into the formula, and take α as 20 degrees. When no quantum dot color film is made on the upper surface of the substrate, 50% of the light can be fully emitted on the upper surface of the substrate 2 . When the α angle is adjusted to 20 degrees, 65% of the light is totally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com