Current transformer

A technology for current transformers and secondary windings, applied in the direction of inductors, transformers/inductor coils/windings/connections, circuits, etc., can solve the problem of large partial discharge of current transformers, reduce partial discharge, and reduce production cost, ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

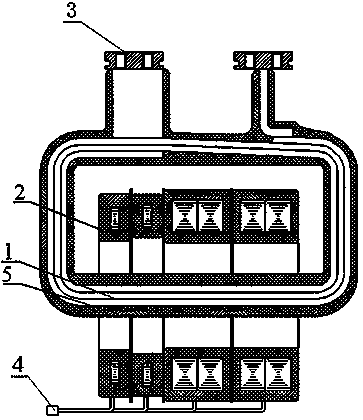

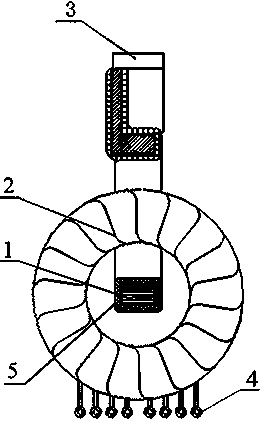

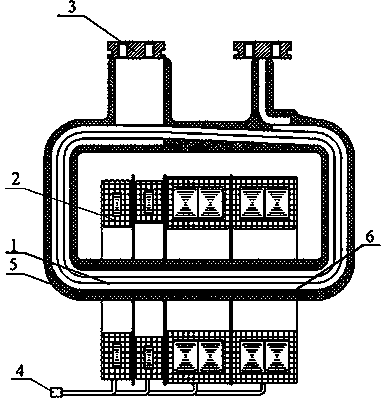

[0025] An embodiment of the current transformer of the present invention includes a cast insulator and a primary winding 1 and a secondary winding 2 sealed in the cast insulator, wherein the primary winding 1 and the secondary winding 2 are such as image 3 and Figure 4 As shown, the secondary winding 2 is circular, and the primary winding 1 is rectangular. The secondary winding 2 is sleeved on the lower side of the primary winding 1 and located on the winding path of the primary winding 1 . Among them, the primary winding 1 is wound by copper tape, and its cross-section is rectangular, and the two ends of the copper tape are connected with the primary terminal 3 ; the secondary winding 2 is connected with the secondary terminal 4 .

[0026] The upper and lower sides of the lower side of the primary winding 1 are provided with a spacer 6 respectively. The spacer 6 is a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com