A kind of nougat sandwich crispy rice and its processing technology

A technology for nougat and rice noodles, which is applied in the field of snack food, can solve the problems of inability to satisfy the concept of health, inability to satisfy the consumer market, complicated production methods, etc., and achieve the effects of ensuring food safety, efficient processing, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

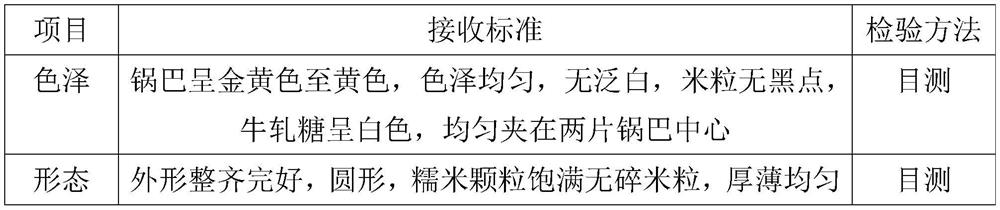

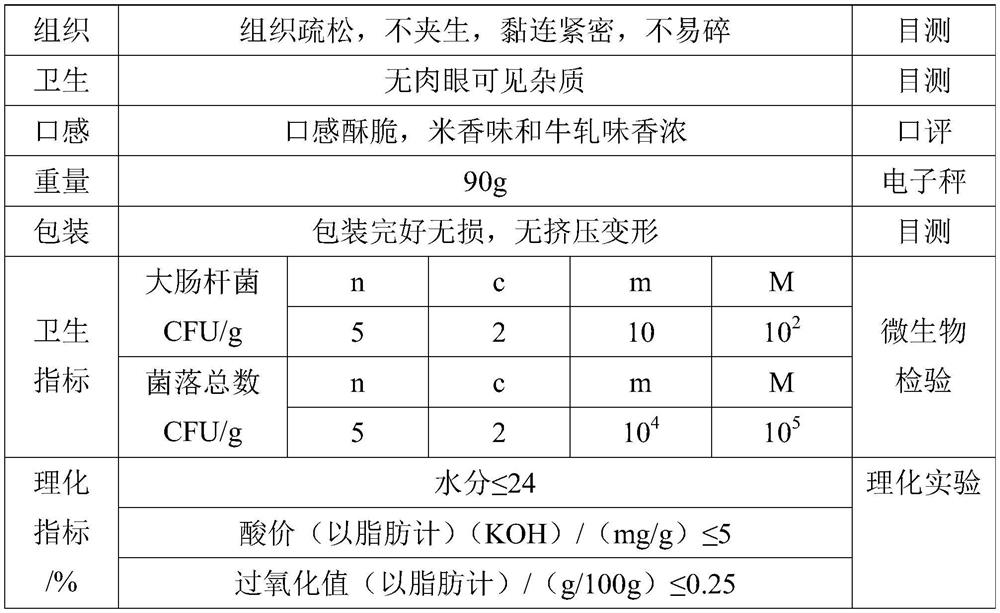

[0036] Processing of nougat sandwich crispy rice:

[0037] (1) Soaking: Soak the selected high-quality glutinous rice at a water temperature of 25°C, rinse with water after 10 hours, and drain the surface moisture;

[0038] (2) Weighing: take each raw material respectively according to the proportioning ratio;

[0039] (3) Stirring: Mix 50kg of glutinous rice, 5kg of palm oil, 1kg of cornstarch, and 1kg of salt, first stirring clockwise and then counterclockwise, so that the raw materials are evenly mixed;

[0040] (4) Frying: Put the mixed raw materials into the fryer and fry until the crispy rice is golden yellow to yellow, uniform in color, without whitening or black spots;

[0041] (5) Inspection of semi-finished products: check the color and taste of crispy rice;

[0042] (6) Cooling: Naturally cool the crispy rice to room temperature, and record the temperature and humidity in the packaging room;

[0043] (7) Sandwich: Heat 18.75kg of nougat until it melts, then sandw...

Embodiment 2

[0051] Processing of nougat sandwich crispy rice:

[0052] (1) Soaking: Soak the selected high-quality glutinous rice at a water temperature of 25°C, rinse with water after 10 hours, and drain the surface moisture;

[0053] (2) Weighing: take each raw material respectively according to the proportioning ratio;

[0054] (3) Stirring: Mix 50kg of glutinous rice, 5kg of palm oil, 1kg of cornstarch, 1kg of salt, and 0.8kg of brittleness regulator, first stirring clockwise and then counterclockwise, so that the raw materials are evenly mixed;

[0055] (4) Frying: Put the mixed raw materials into the fryer and fry until the crispy rice is golden yellow to yellow, uniform in color, without whitening or black spots;

[0056] (5) Inspection of semi-finished products: check the color and taste of crispy rice;

[0057] (6) Cooling: Naturally cool the crispy rice to room temperature, and record the temperature and humidity in the packaging room;

[0058] (7) Sandwich: Heat 18.75kg of n...

Embodiment 3

[0068] Processing of nougat sandwich crispy rice:

[0069] (1) Soaking: Soak the selected high-quality glutinous rice at a water temperature of 25°C, rinse with water after 10 hours, and drain the surface moisture;

[0070] (2) Weighing: take each raw material respectively according to the proportioning ratio;

[0071] (3) Stirring: Mix 50kg of glutinous rice, 5kg of palm oil, 1kg of cornstarch, 1kg of salt, and 1kg of brittleness modifier, first stirring clockwise and then counterclockwise, so that the raw materials are evenly mixed;

[0072] (4) Frying: Put the mixed raw materials into the fryer and fry until the crispy rice is golden yellow to yellow, uniform in color, without whitening or black spots;

[0073] (5) Inspection of semi-finished products: check the color and taste of crispy rice;

[0074] (6) Cooling: Naturally cool the crispy rice to room temperature, and record the temperature and humidity in the packaging room;

[0075] (7) Sandwich: Heat 18.75kg of noug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com