Hydrocolloid core dressing and preparation method thereof, hydrocolloid dressing and application thereof

A hydrocolloid and hydrophilic colloid technology, applied in dressings, viscous dressings, non-adhesive dressings, etc., can solve the problems of decreased skin fit performance, slow liquid absorption rate, large liquid absorption of dressings, etc. Flexibility, adjustable suction rate, fast suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

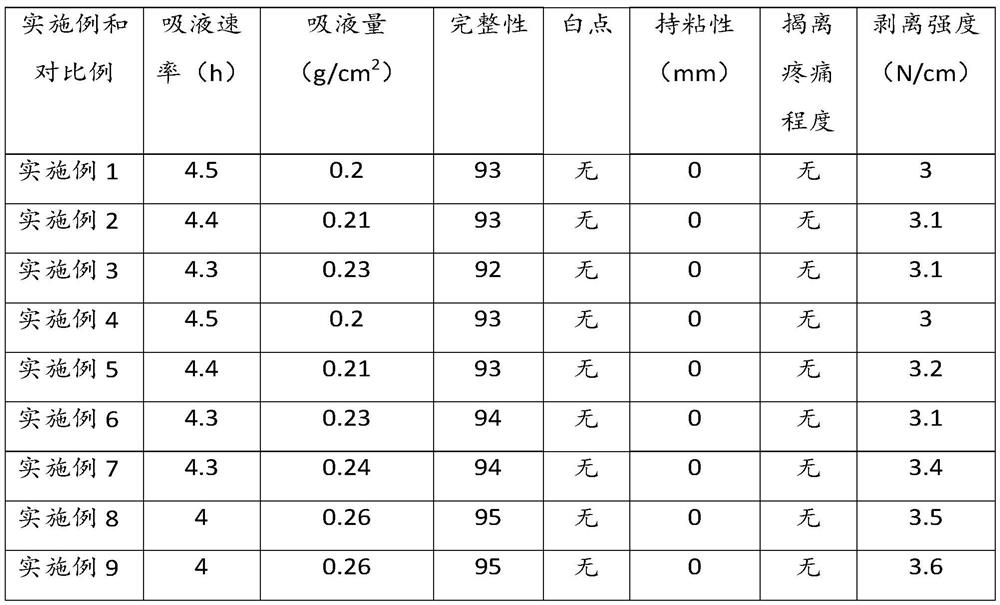

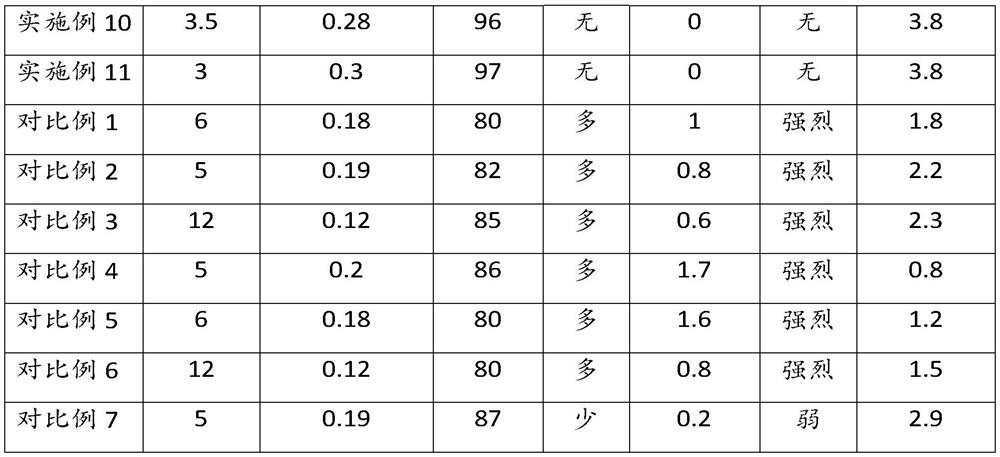

Examples

preparation example Construction

[0084] The preparation method of above-mentioned hydrocolloid coating core, comprises the following steps:

[0085] The thermoplastic rubber, the plasticizer, the tackifying resin, the reinforcing agent, the antioxidant, the hydrophilic colloid and the wetting-promoting absorbent are uniformly mixed according to the ratio to obtain the hydrocolloid coating core. The preparation method of the hydrocolloid dressing has simple operation and high controllability.

[0086] The preparation method of hydrocolloid core as above, described method comprises the following steps:

[0087] (a) adding thermoplastic rubber, plasticizer, tackifying resin, reinforcing agent and antioxidant in the kneader, mixing evenly;

[0088] (b) adding a hydrophilic colloid and a wetting-promoting absorbent to the homogeneous mixture in step (a), stirring to obtain a hydrocolloid core coating;

[0089] Preferably, the mixing temperature in the step (a) is 80-130°C, the mixing time is 55-65min, and the kn...

Embodiment 1

[0108] A hydrocolloid coating core is mainly made of the following raw materials in parts by weight:

[0109] 25 parts of hydrophilic colloid, 10 parts of wet-absorbing agent, 1 part of thermoplastic rubber, 30 parts of plasticizer, 4 parts of tackifying resin, 13 parts of reinforcing agent and 0.008 part of antioxidant.

Embodiment 2

[0111] A hydrocolloid coating core is mainly made of the following raw materials in parts by weight:

[0112] 50 parts of hydrophilic colloid, 0.5 parts of wet-absorbing agent, 20 parts of thermoplastic rubber, 8 parts of plasticizer, 30 parts of tackifying resin, 1.5 parts of reinforcing agent and 4 parts of antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com