A kind of preparation method of fluoride gel polymer electrolyte membrane and lithium ion battery

A gel polymer, electrolyte membrane technology, applied in the field of lithium ion batteries, can solve the problems of low conductivity, inability to industrialize application, limited effect, etc., achieve high liquid absorption rate, improve room temperature ionic conductivity, and good affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] The fluorinated gel polymer electrolyte membrane described in this embodiment is a copolymer electrolyte membrane of a gelable monomer and a fluorine-containing vinyl monomer, and its preparation method includes the following steps:

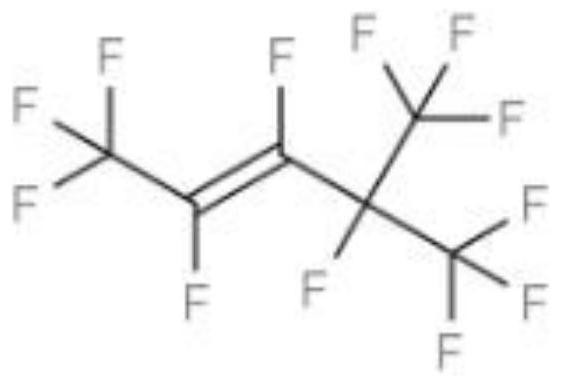

[0033] Step 1: In parts by weight, add 5 to 50 parts of fluorine-containing vinyl monomer, 40 to 80 parts of gelable monomer, and 0 to 10 parts of polyethylene glycol methacrylate monomer to 100 to 300 parts part of solvent, keep nitrogen or inert gas atmosphere, stir at 100~800r / min for 10min-120min, then add 0.05~1.00 part of initiator, then react at 60℃~110℃ for 5~48h, and obtain after purification Polymer A;

[0034] Step 2: In parts by weight, add 30-80 parts of polymer A and 0-20 parts of filler into 100-300 parts of solvent, stir at a speed of 100-800 r / min under dry nitrogen or inert gas atmosphere, and stir 1 to 10 hours, then add 0 to 2.00 parts of hydroxyl crosslinking agent into the mixed system, and the mixed solution is even...

Embodiment 1

[0047] A kind of fluoride gel polymer electrolyte membrane is the copolymer electrolyte membrane of gelable monomer and fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

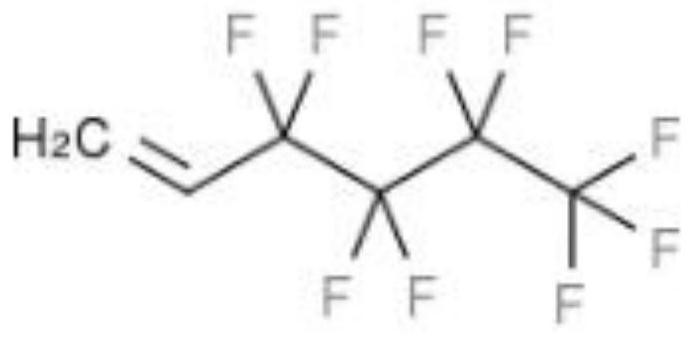

[0048] Step 1: In parts by weight, 3 parts of 1H,1H,2H-perfluoro-1-hexene, 2 parts of octafluoropentyl methacrylate, 50 parts of polyethylene glycol methyl ether acrylate, 30 parts Methyl methacrylate, 2 parts of polyethylene glycol methyl methacrylate with a molecular weight of 300, and 1 part of polyethylene glycol monoallyl ether with a molecular weight of 2400 are added to 100 parts of toluene, and nitrogen gas is continued to flow at 800r / Stir at a speed of min for 10 min, then add 1.00 parts of azobisisobutyronitrile, then react at 60°C for 48 h, and obtain polymer A after purification;

[0049] Step 2: In parts by weight, add 80 parts of polymer A, 8 parts of nano-silica, 8 parts of lithium titanate, and 4 parts of lithium aluminosilicate to 100 parts of ace...

Embodiment 2

[0053] A kind of fluoride gel polymer electrolyte membrane is the copolymer electrolyte membrane of gelable monomer and fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

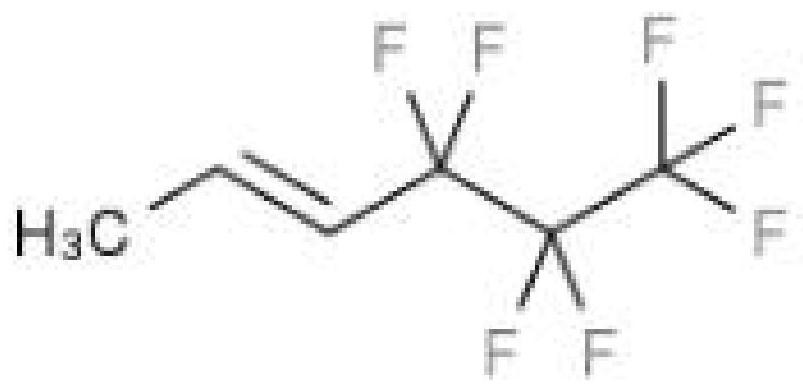

[0054] Step 1: In parts by weight, 20 parts of 4,4,5,6,6,6-octafluoro-2-hexene, 30 parts of hexafluorobutyl methacrylate, 30 parts of isobutyl methacrylate ester, 10 parts of polyethylene glycol methyl ether methacrylate, 1 part of polyethylene glycol methyl methacrylate with a molecular weight of 2500, 5 parts of polyethylene glycol monoallyl ether with a molecular weight of 100, and 300 parts of benzene In the middle, continue to flow argon, stir at a speed of 100r / min for 120min, then add 0.05 parts of benzoyl peroxide, then react at 110°C for 36h, and obtain polymer A after purification;

[0055] Step 2: In parts by weight, 30 parts of polymer A, 5 parts of nano-aluminum oxide, 4 parts of lithium titanium aluminum phosphate, and 2 parts of lithium lanthanum tant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com