Cutting device and method for fiber web winding machine

A technology of cutting device and fiber web, which is applied in the direction of winding mechanism, winding strip, fiber processing, etc., can solve the problem of unreliable arrival of fiber web to the winding shaft, etc., and achieve the effect of simple structure and no waste of operating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

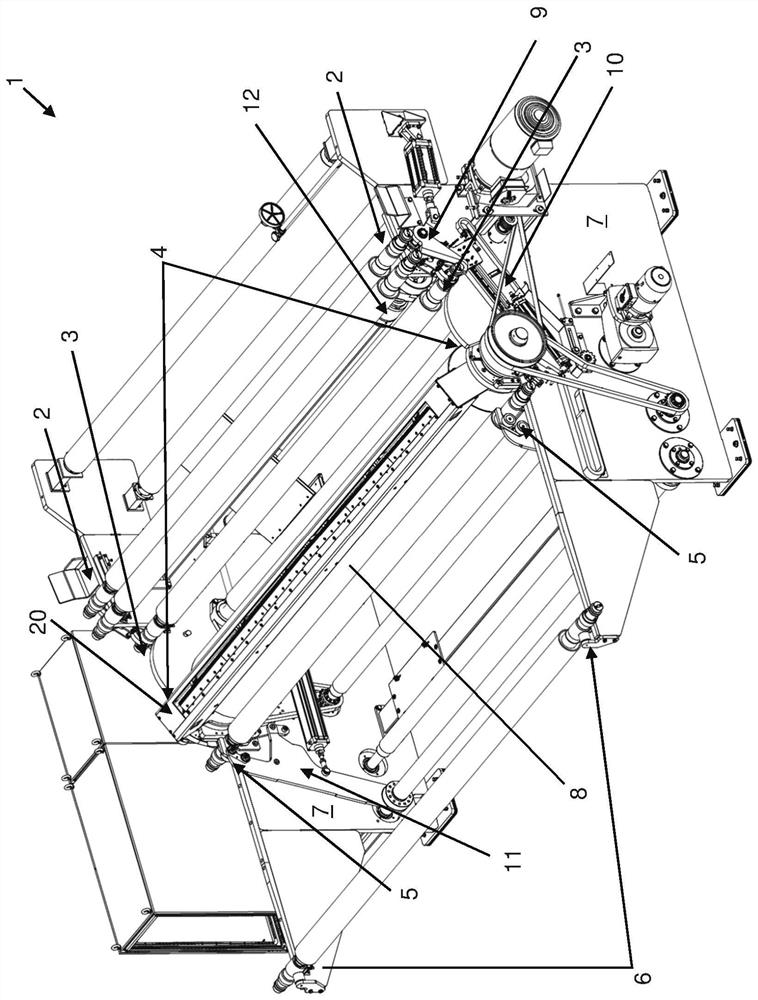

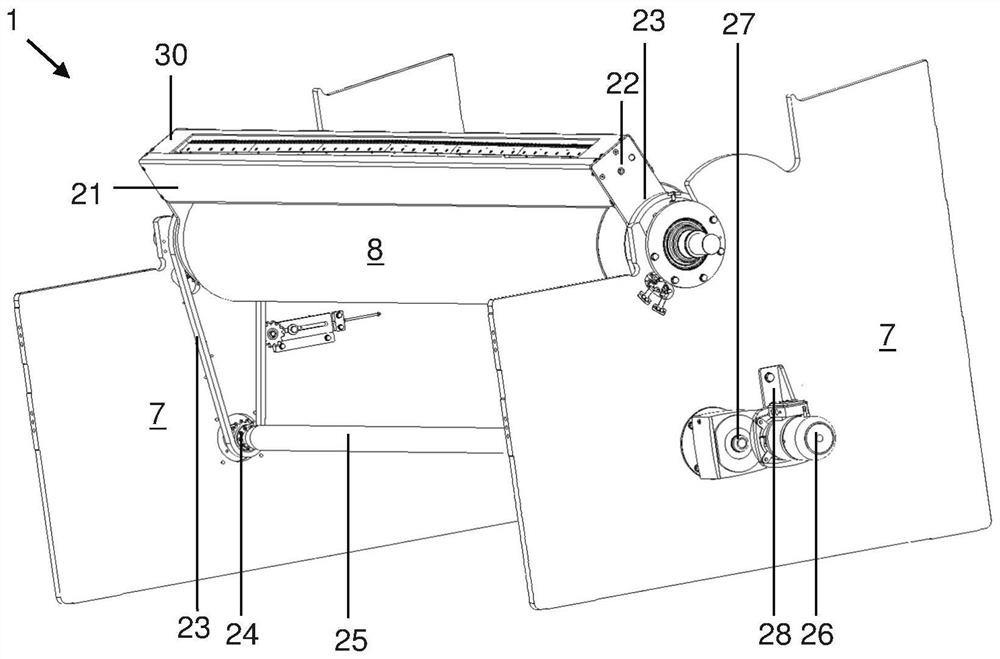

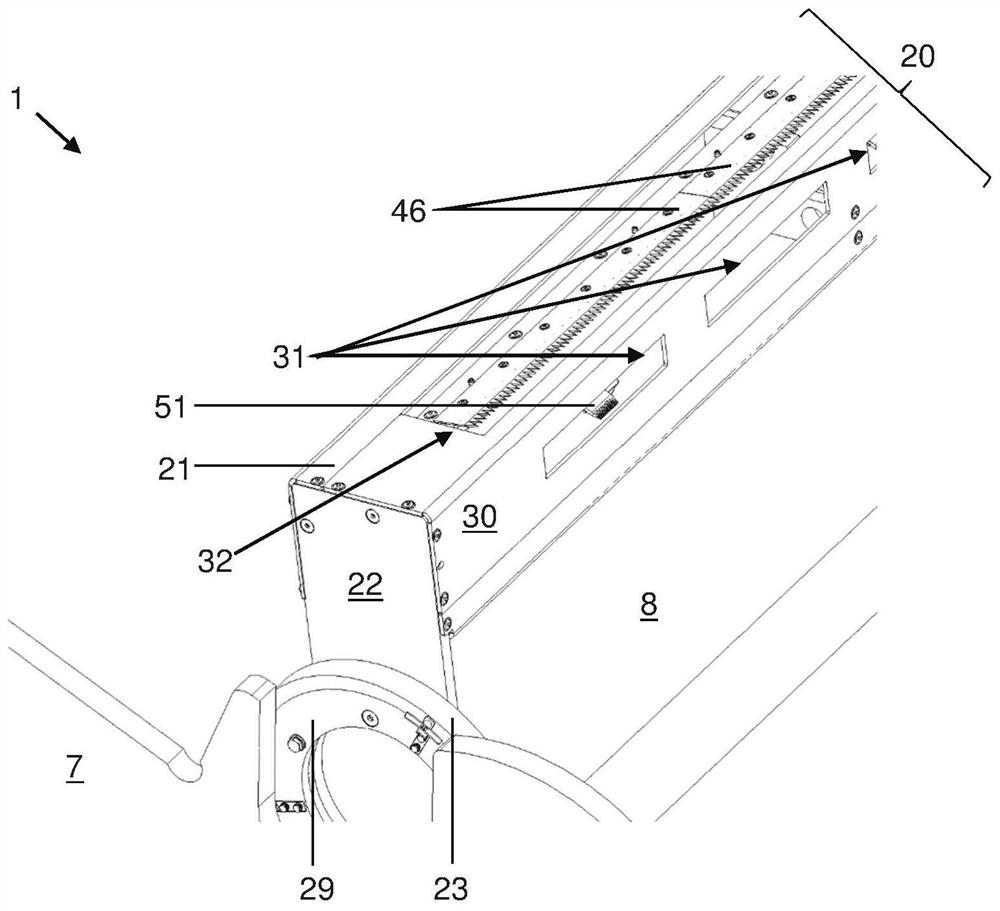

[0028] figure 1 A web winding machine 1 according to an embodiment of the invention is shown. Components that are not essential to the invention will not be explained further.

[0029] The web winding machine 1 essentially comprises two frame walls 7 , which form a frame by means of connecting bodies, not shown, which accommodate or hold all other functional components of the web winding machine 1 .

[0030] On the right, the machine frame wall 7 has a depository 2 in which not shown (here: two) winding shafts are located.

[0031]The web winder 1 also comprises a recess on each frame wall 7 which defines a waiting position 3 for the winding shaft. Since the winding shaft is held on both sides by the respective frame wall 7 , the waiting position 3 is realized with two frame walls 7 .

[0032] In the waiting position 3 , the winding shaft arranged in the waiting position is set into rotation by means of the starting section 12 . Here, the start-up section 12 contacts the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com