Method for recycling and utilizing dyeing liquor of dye for a full polyamide fabric

A technology for dyeing liquid and dyeing residue, which is applied in the fields of dyeing, textiles and papermaking, can solve the problems of long processing time, high operation and recycling costs, and achieve the effect of reducing sewage discharge and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

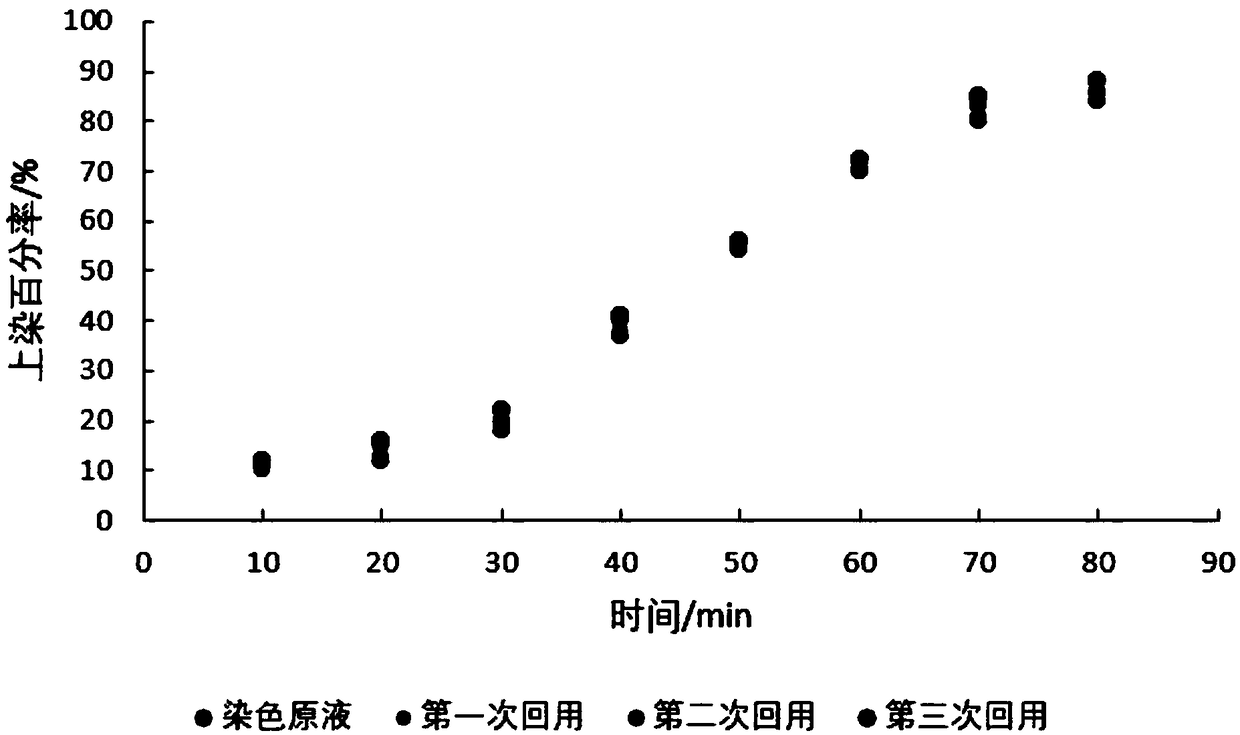

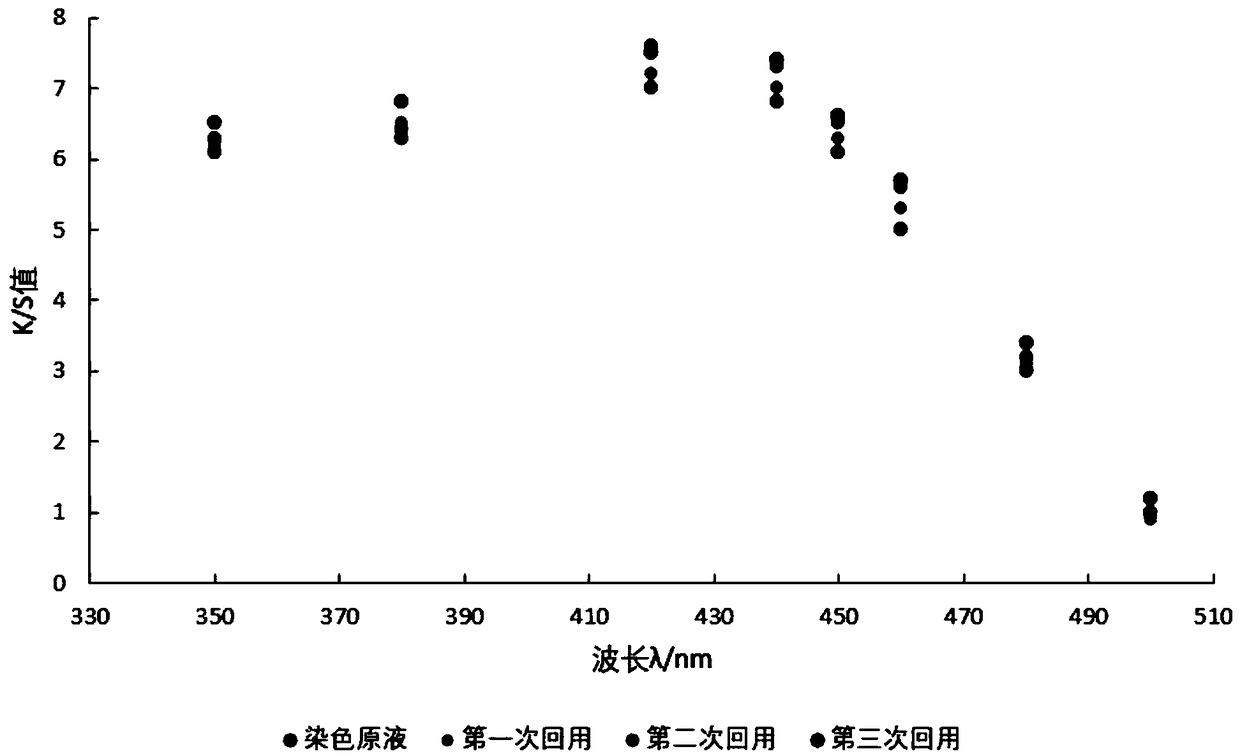

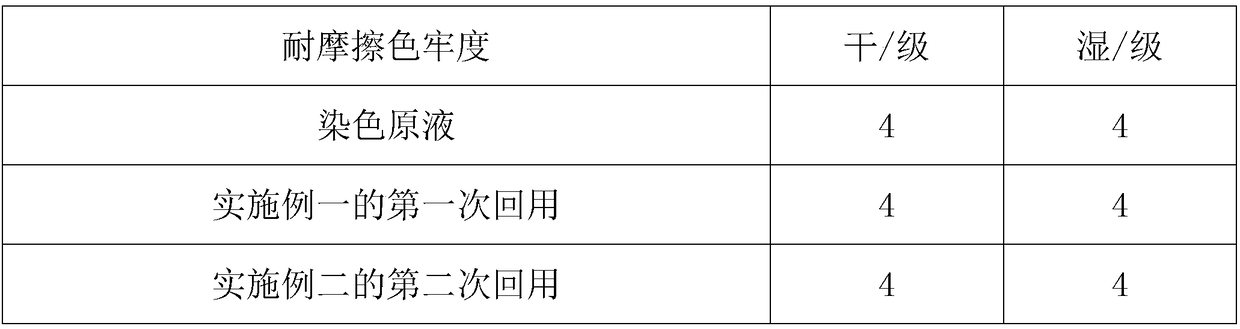

[0040](1) Use a 500ml graduated cylinder to measure 200mL of the above standard dye solution into a 250mL glass dyeing cup, add 1g of sodium chloride, stir and dissolve completely, put the full nylon fabric soaked in warm water and squeezed dry in advance into the dyeing solution to start dyeing , and place the glass dyeing cup in a constant temperature water bath and heat it up to 40°C. At 40°C, dye at a constant temperature for 5 minutes, then at a heating rate of 1°C / min, raise the temperature to 90°C, and at 90°C, dye at a constant temperature for 30 minutes. After dyeing, take out the all-nylon fabric for washing and drying;

[0041] (2) Add distilled water to the dyeing residue in step (1), dilute to the scale of the 250mL glass dyeing cup, use a 5mL pipette to draw 4mL of the residue into a 50mL volumetric flask, dilute to the mark with distilled water, Under the maximum absorption wavelength λmax, measure the absorbance A of the dyeing residue, read the corresponding d...

Embodiment 2

[0045] (1) Add distilled water to the dyeing residue in step (3) of Example 1, dilute to the scale of the 250mL glass dyeing cup, draw 4mL of the residue into a 50mL volumetric flask with a 5mL pipette, and dilute to the mark with distilled water , under the maximum absorption wavelength λmax of the standard dye, measure the absorbance A of the dyeing residue, read the corresponding dye concentration (c%) on the working curve, and calculate the dye content in the dyeing residue;

[0046] (2) Supplement the required dye and leveling agent to the dyeing residue in step (1), adjust the pH value to be the same as the stock solution, draw 4mL of recycled dyeing solution in a 50mL volumetric flask with a 5mL pipette, and dilute it with distilled water to Scale, under the maximum absorption wavelength λmax of the standard dye, measure the absorbance A of the recycled dyeing solution, the result is the same as the absorbance A of the dyeing stock solution, and make the second reused dy...

Embodiment 3

[0049] (1) Add distilled water to the dyeing residue in step (3) of Example 2, dilute to the scale of the 250mL glass staining cup, draw 4mL of the residue into a 50mL volumetric flask with a 5mL pipette, and dilute to the mark with distilled water , under the maximum absorption wavelength λmax of the standard dye, measure the absorbance A of the dyeing residue, read the corresponding dye concentration (c%) on the working curve, and calculate the dye content in the dyeing residue;

[0050] (2) Supplement the required dye and leveling agent to the dyeing residue in step (1), adjust the pH value to be the same as the stock solution, draw 4mL of recycled dyeing solution in a 50mL volumetric flask with a 5mL pipette, and dilute it with distilled water to scale, under the maximum absorption wavelength λmax of the standard dye, measure the absorbance A of the recycled dyeing solution, the result is the same as the absorbance A of the dyeing stock solution, and the third reused dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com