Heat insulation structure for two-cylinder type LNG low temperature storage tank

A low-temperature storage tank and heat-insulating structure technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of increasing the weight of double-barreled LNG low-temperature storage tanks, increasing power transportation costs, etc. Achieve the effect of reducing the cost of power transportation, improving the effect of heat insulation, and excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

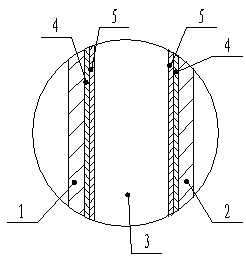

[0014] figure 1 Schematic diagram of the structure of the present invention, paste 12-13 layers of heat-insulating paper 4 on the inner wall of the outer tank 1 and the outer wall of the inner tank 2, and then stick the heat-insulating paper 4 with the lens 5 on the heat-insulating paper layer, the interlayer between the inner and outer tanks 3 Vacuum, vacuum degree ≤ 0.001Pa. In order to avoid the impact of impurities in the production process on the thermal insulation performance, an AG molecular sieve low-temperature adsorption device is installed in the interlayer 3 of the inner and outer tanks.

[0015] Before the assembly, the lens 5 is pasted on the heat-insulating paper 4 in advance, and then pasted on the heat-insulating paper layer on the inner wall of the outer tank 1 and the outer wall of the inner tank 2. In order to ensure a good fit, the lens 5 is matched with the arc of the sticking surface curved lenses or small size flat lenses.

[0016] When welding the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com