Thermal Insulation Construction Technology of LNG Cryogenic Transmission Pipeline

A technology for liquefied petroleum and transportation pipelines, applied in thermal insulation, pipeline protection, heat exchange equipment, etc., can solve the problems of reduced pipeline insulation capacity, poor weather resistance of molds, failure of thermal insulation effect, etc., to reduce labor intensity and achieve good performance , Improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

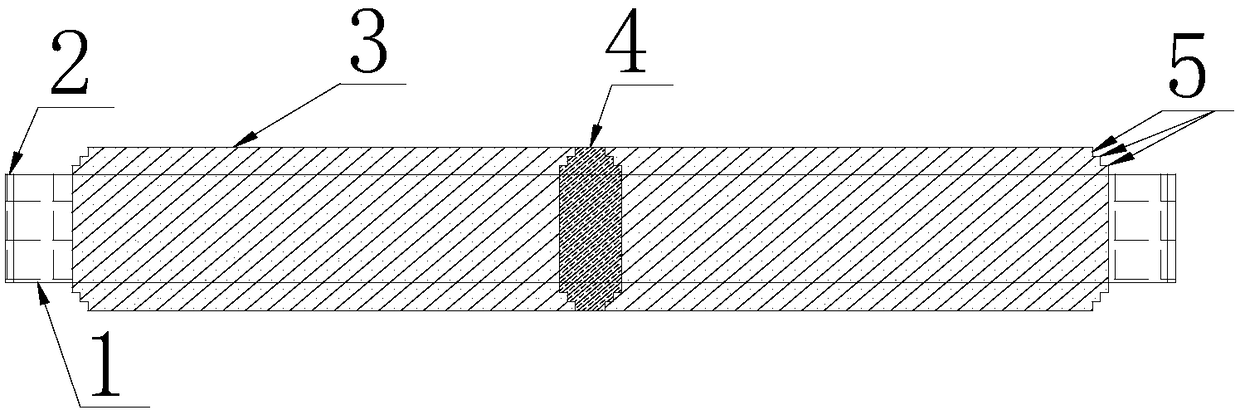

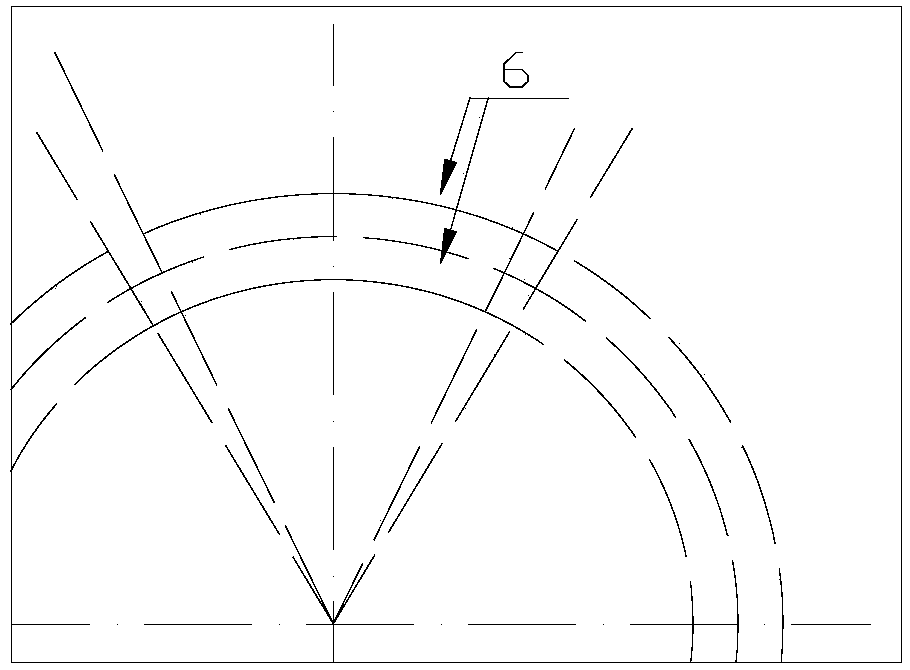

[0045] Such as figure 1 — figure 2 As shown, the present invention includes two parts: indoor pre-insulation and outdoor heat insulation. Among them, indoor pre-insulation is foamed with cyanate ester and polyether as the main raw materials, and is evenly sprayed on the pipeline by specific equipment to form a polyurethane insulation layer. 5, a heat insulation method, the heat insulation layer is a three-layer structure; the following construction steps are used for indoor pre-insulation:

[0046] The first step: install the shear key 4 in the middle of the pipeline 1 that has been sprayed; it is used as the innermost layer of the pipeline 1 for heat insulation; the specific steps for installing the shear key 4 are as follows:

[0047] 1. Scrape off the coating of the pipeline 1 at the installation position of the shear key 4. The scraped length should be slightly less than the total length of the shear key 4, and there should be 10mm of coating at each end below the shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com