Artemisia selengensis reaping machine with screening function

A harvester and artemisia technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as jamming artemisia, carrying a lot of dust and soil, and easy damage to the harvester, so as to achieve convenient operation and Clean and well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

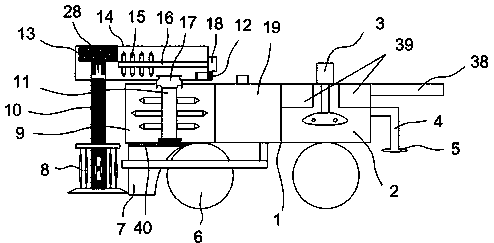

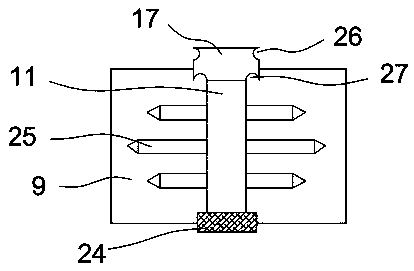

[0022] Such as Figure 1-3 , shown in 6, the scheme that the present invention takes for realizing the above-mentioned purpose is: the artemisia harvester with screening function, comprises machine bin I1, is provided with machine bin II14 above the machine bin II14, connects the harvesting device 8 below the front end of the machine bin II14, A connector 38 is provided at the tail of the machine compartment I1, and the inside of the machine compartment I1 is provided with a crushing box 9, a cleaning box 19, and a fertilization box 2 in sequence, and a motor 24 is installed at the bottom of the crushing box 9, and the output end of the motor 24 is connected to the rotating shaft I11, and the surface of the rotating shaft I11 is uniform. The upper end of the rotating shaft I11 is connected with the machine bin II14 through the suction block 17, the lower end of the machine bin I1 is provided with a roller 6, and a baffle plate 7 is provided between the roller 6 and the harvesti...

Embodiment 2

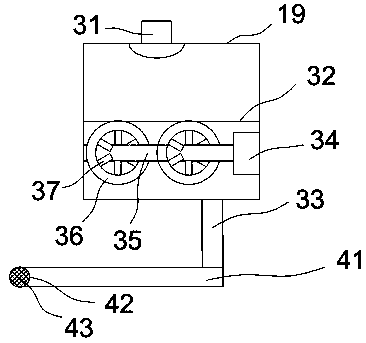

[0029] Such as Figure 4-5 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the harvesting device 8 includes a rotating shaft 10, the upper end of the rotating shaft 10 is connected with the motor I13 in the machine compartment II14, and the bottom end of the rotating shaft 10 is connected with a cutting disc 20, above the cutting disc 20, there is a disc 21 socketed on the surface of the rotating shaft 10, and a diamond-shaped blade 22 is arranged around the cutting disc 20 and the disc 21. The motor Ⅰ drives the cutting disk connected to the bottom end of the rotating shaft to rotate, thereby cutting the Artemisia in front of the cutting disk, through the cutting of the cutting disk, the cutting edge of the cut Artemisia is made flat, and the uneven cutting does not cause harm to personnel. At the same time, the diamond-shaped blades distributed between the cutting disc and the disc can further rotate and shear the cut and lodging artemis...

Embodiment 3

[0033] The working principle of the artemisia harvester with screening function of the present invention is: connect the connector 38 of the device to the power source, run to the area where harvesting is required, start the motor I13 to work, and drive the harvesting device 8 to rotate the artemisia through the rotating shaft 10 Harvesting, the harvested artemisia is rotated and squeezed into the suction hole 23, and the motor I13 drives the rotating shaft III30 arranged on the inside of the rotating shaft to rotate, so that the screw rod 29 connected to the surface of the rotating shaft III30 spirals the artemisia in the rotating shaft 10 upwards. Conveying, under the action of the suction fan 12, the artemisia is sucked out from the convex hole 28 on the upper surface of the rotating shaft 10 to the inside of the machine compartment II14, and the artemisia after crushing is further crushed by the shredded pieces II15. The artemisia enters the crushing box 9 from the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com