Thick steel plate submerged arc penetration welding back-chipping-free welding method and groove structure thereof

A welding method and welding groove technology, which are applied to welding equipment, arc welding equipment, and the edge of workpieces, etc., can solve the problems of large loss, long welding time, etc., achieve good quality, high welding efficiency, save time and economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

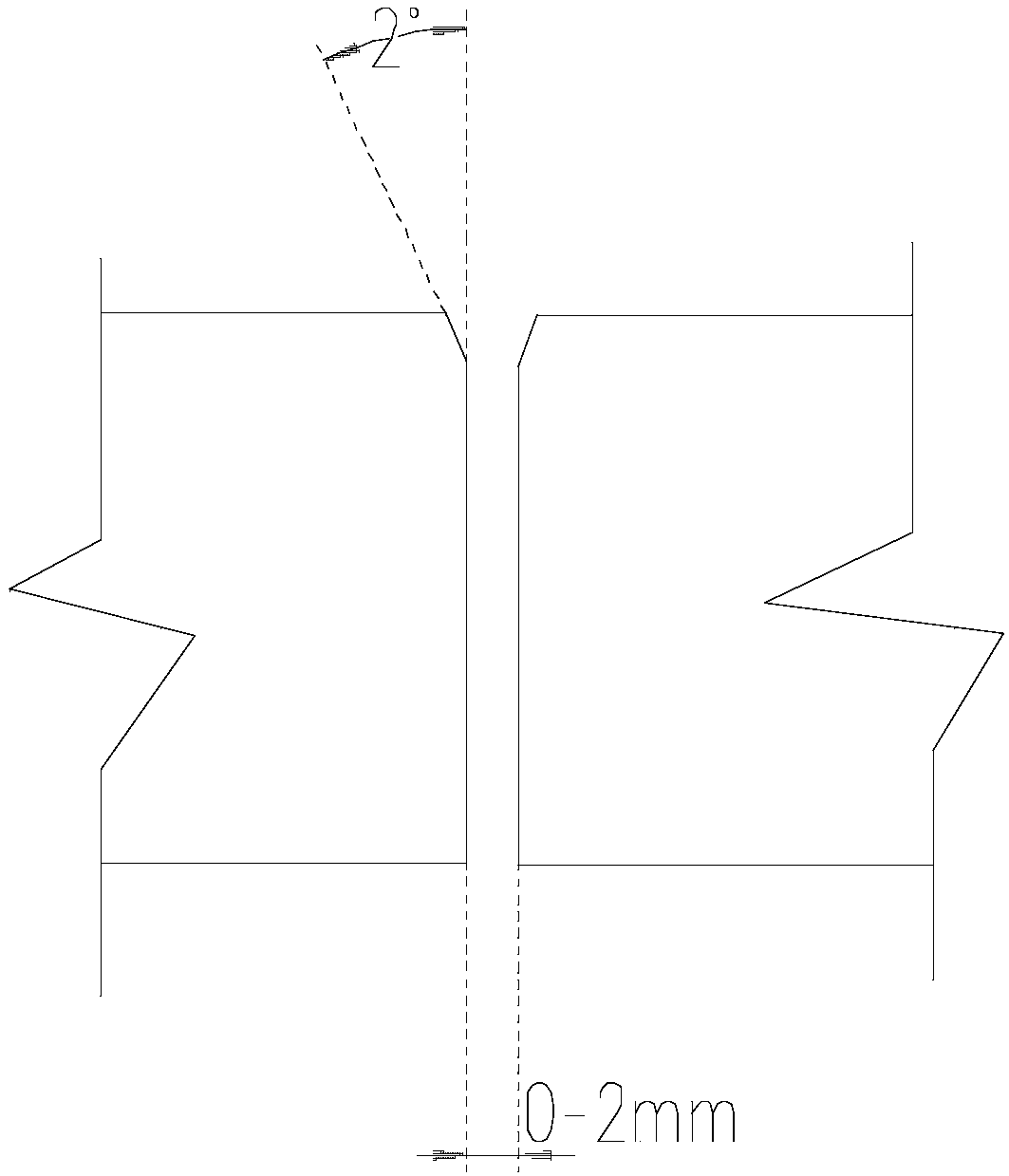

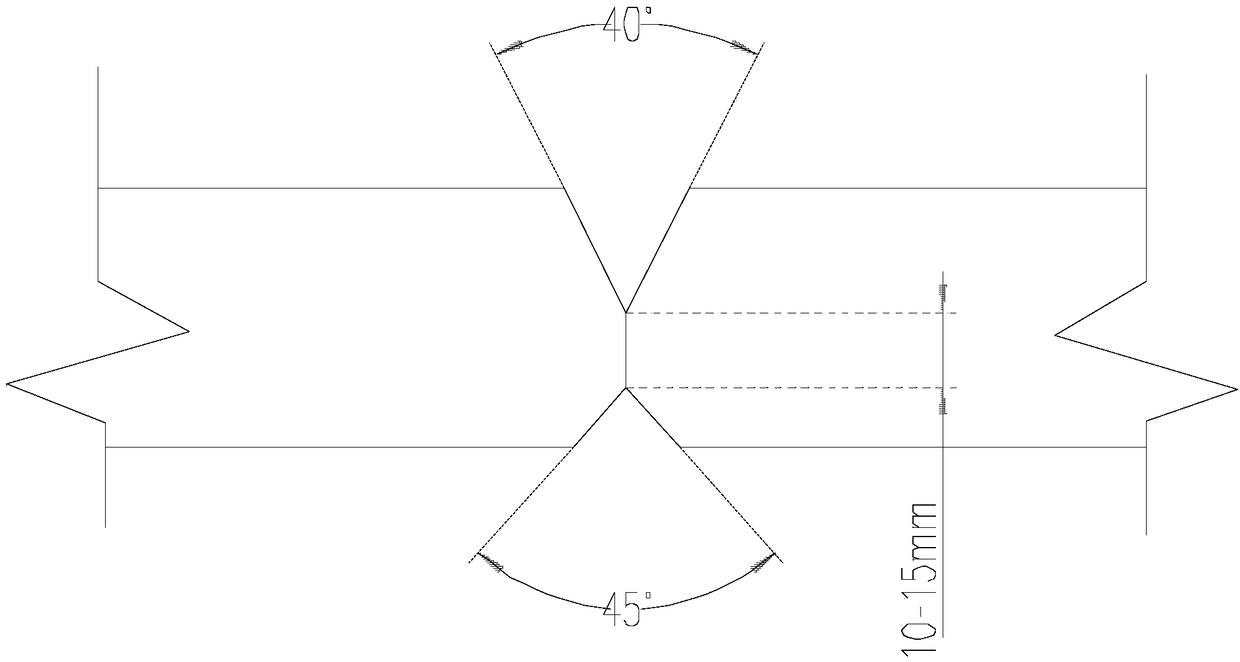

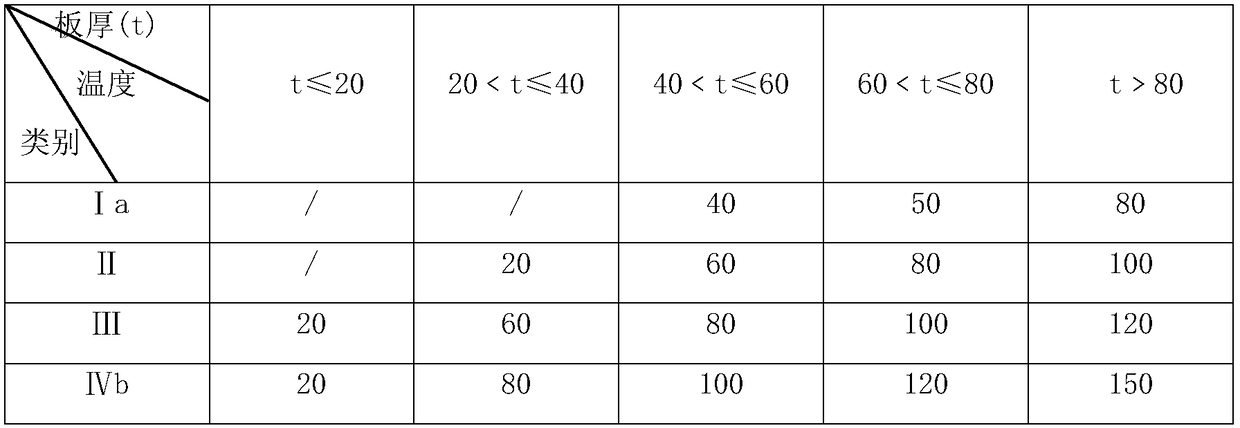

[0039]The submerged arc penetration welding method for thick steel plates without root cleaning comprises the following steps: (a) determining the welding groove positions of two steel plates with equal thickness, and performing flaw detection on the area of the two steel plates within the width range of 2t at the edge of the groove; Replace the steel plate that is defective in the flaw detection; where t is the thickness of the steel plate; (b) Cut and blank the two steel plates according to the actual size of the required component; (c) Open the butt joint groove: if t≤30mm, the butt joint groove Open as type I; if 30mm<t≤100mm, the butt joint groove is opened as reserved blunt edge X-shaped groove, where the included angle of the X-shaped groove is 40°, and the thickness of the blunt edge is 10-15mm; (d) The two steel plates and the double-wire welding machine stand in place, and then preheat the two steel plates; adjust the distance between the double wires so that the di...

Embodiment 2

[0041] Submerged arc penetration welding method for thick steel plates without root cleaning, on the basis of Example 1, in step (e), if t≤30mm, the welding speed is 50cm / min, and the assembly gap is between 0 and 2mm; if 30mm< If t≤100mm, the welding speed is 30cm / min, the assembly gap is 0, and the welding arm is adjusted horizontally to the left or right by 3-4mm after each welding seam. In the step (e), when the filling amount of the weld seam reaches 2 / 3 of the front weld seam, the step (f) is entered, and the submerged arc welding back welding is started. The step (f) includes the following steps: if t≤30mm: (A) use a sling to turn the component over, adjust the welding wire to ensure the center of the vertical weld seam; (B) bottom welding: make the front wire current 950A, voltage 32V, Welding torch angle is 0°, rear wire current is 550A, voltage is 42V, welding torch angle is 12°, and the speed of 50cm / min is used for bottom welding; The wire current is 580A, the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com