Flux

A technology of flux and surfactant, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of inability to spread evenly, unable to form solder bumps, damage to soldering reliability, etc. , to achieve a good effect of infiltration and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

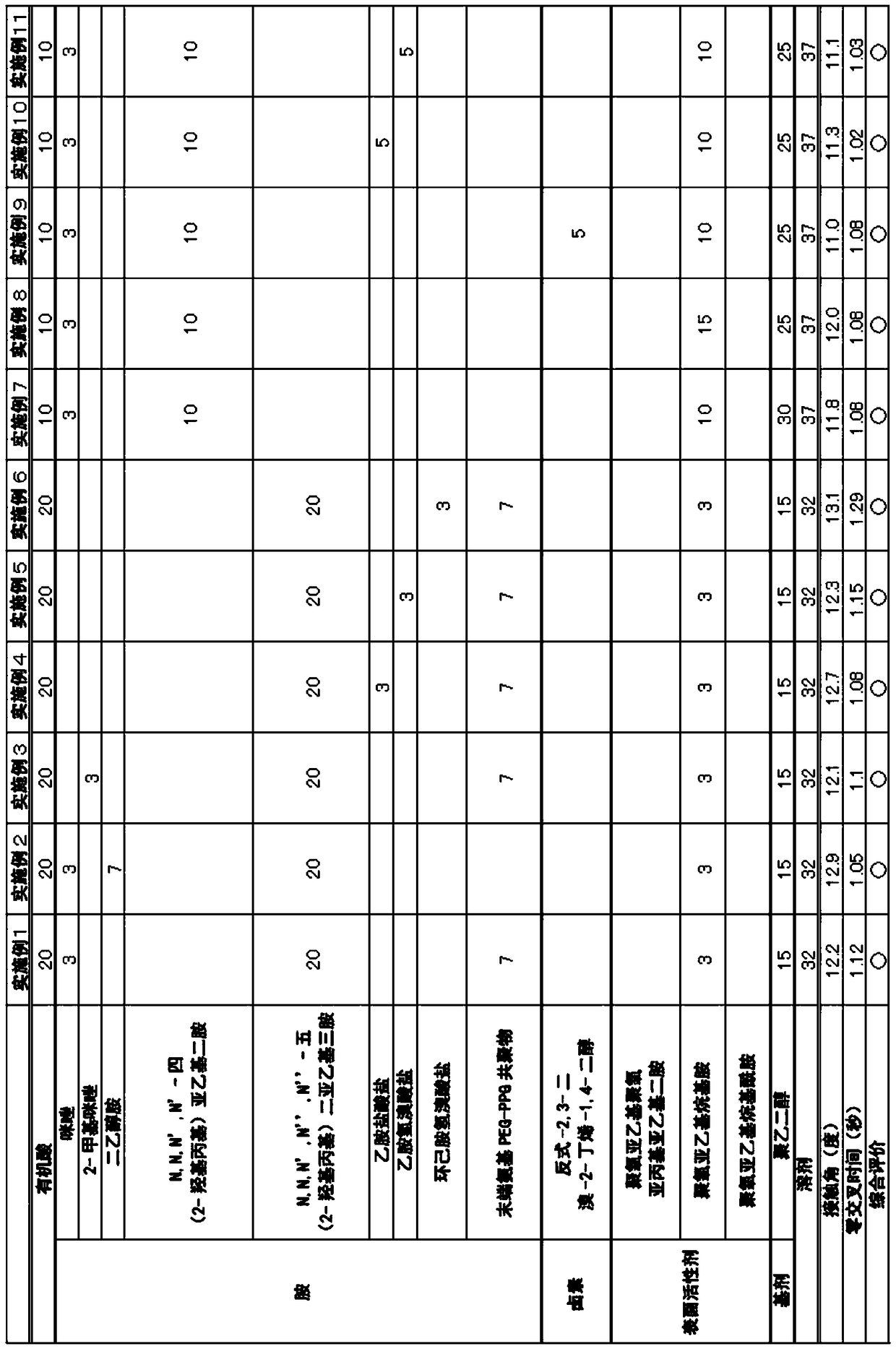

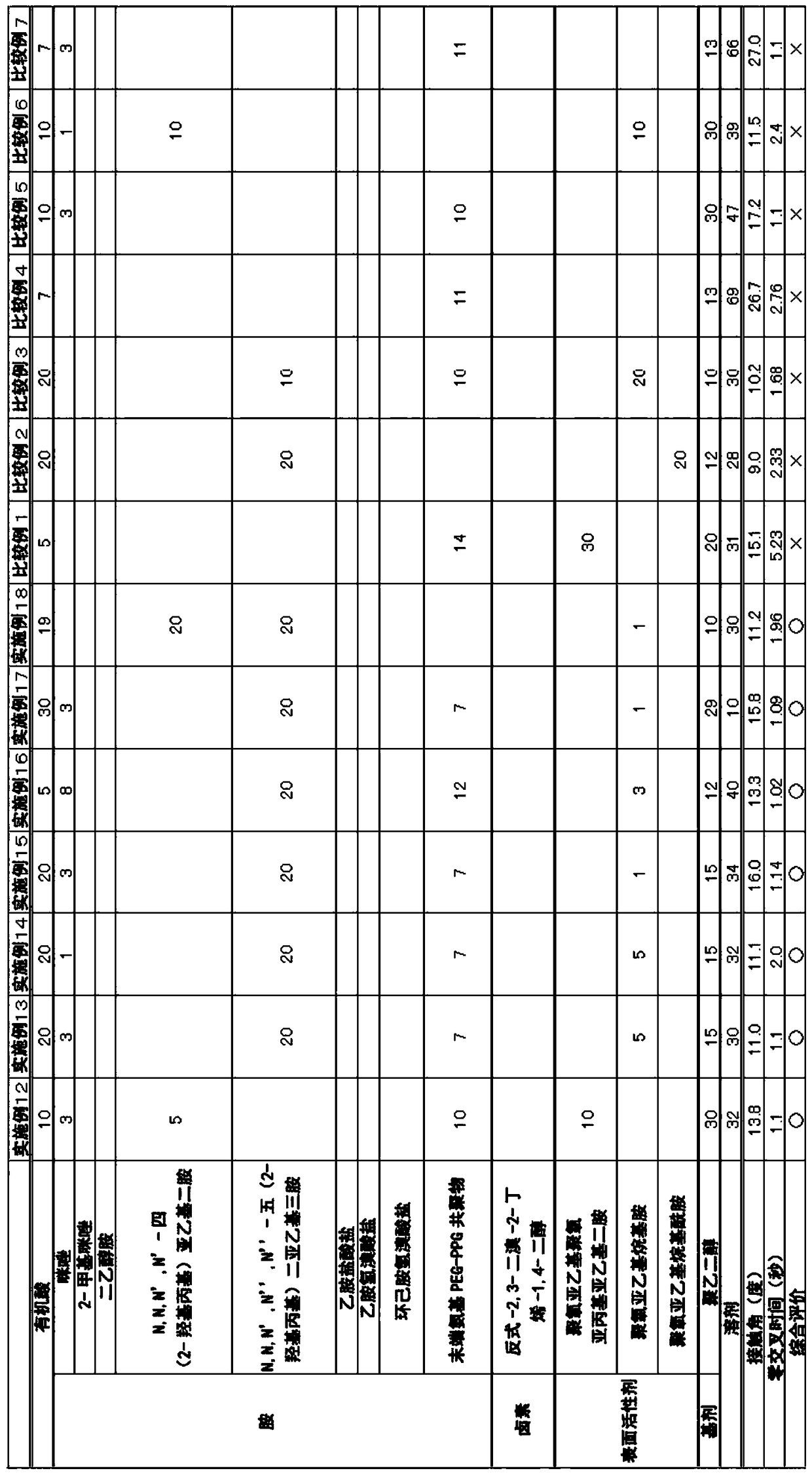

Embodiment 1

[0053] The flux of Example 1 contains: 20% by mass of an organic acid, 3% by mass of imidazole as an amine, and N,N,N',N",N"-penta(2-hydroxypropyl)diethylene as an amine 20% by mass of triamine, 7% by mass of amino-terminated PEG-PPG copolymer as amine, 3% by mass of polyoxyethylene alkylamine as surfactant, 15% by mass of polyethylene glycol as base, solvent 32% by mass. With the flux of Example 1, good results were obtained, such as a contact angle of 12.2 degrees and a zero-crossing time of 1.12 seconds.

Embodiment 2

[0054] The flux of Example 2 contains: 20% by mass of organic acid, 3% by mass of imidazole, 7% by mass of diethanolamine as an amine, N,N,N',N",N"-penta(2-hydroxypropyl) di 20% by mass of ethylenetriamine, 3% by mass of polyoxyethylene alkylamine, 15% by mass of polyethylene glycol, and 32% by mass of solvent. The flux of Example 2 was able to obtain good results of a contact angle of 12.9 degrees and a zero-crossing time of 1.05 seconds.

Embodiment 3

[0055] The flux of Example 3 contains: 20% by mass of an organic acid, 3% by mass of 2-methylimidazole as an amine, N,N,N',N",N"-penta(2-hydroxypropyl)diethylene 20% by mass of triamine, 7% by mass of amino-terminated PEG-PPG copolymer, 3% by mass of polyoxyethylene alkylamine, 15% by mass of polyethylene glycol, and 32% by mass of solvent. The flux of Example 3 was able to obtain good results of a contact angle of 12.1 degrees and a zero-crossing time of 1.1 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com