Robot welding-cutting anti-collision device

A robot welding and anti-collision technology, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of large torque variation and poor control accuracy, achieve balance of collision force, realize stable control, and anti-collision work wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

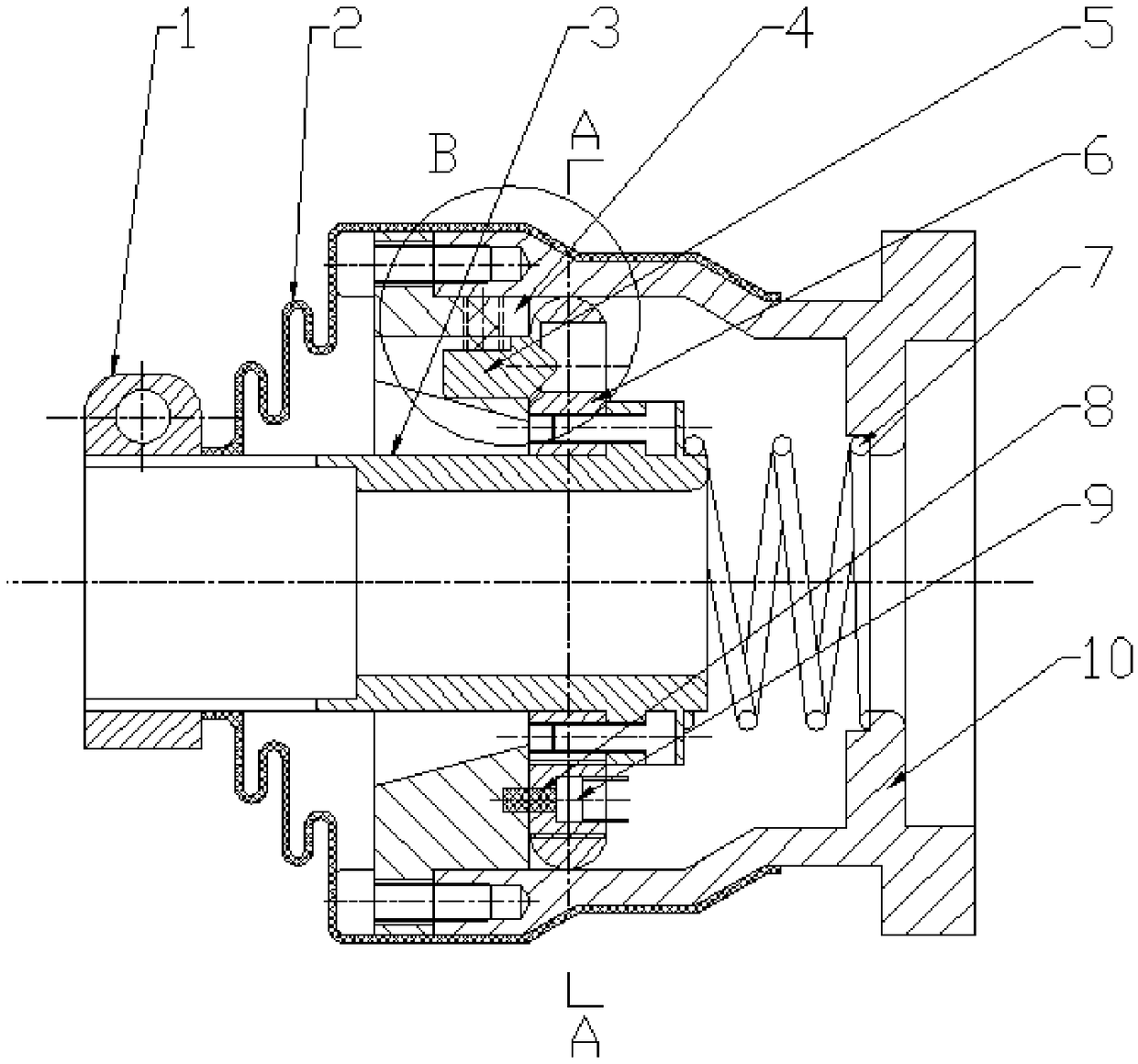

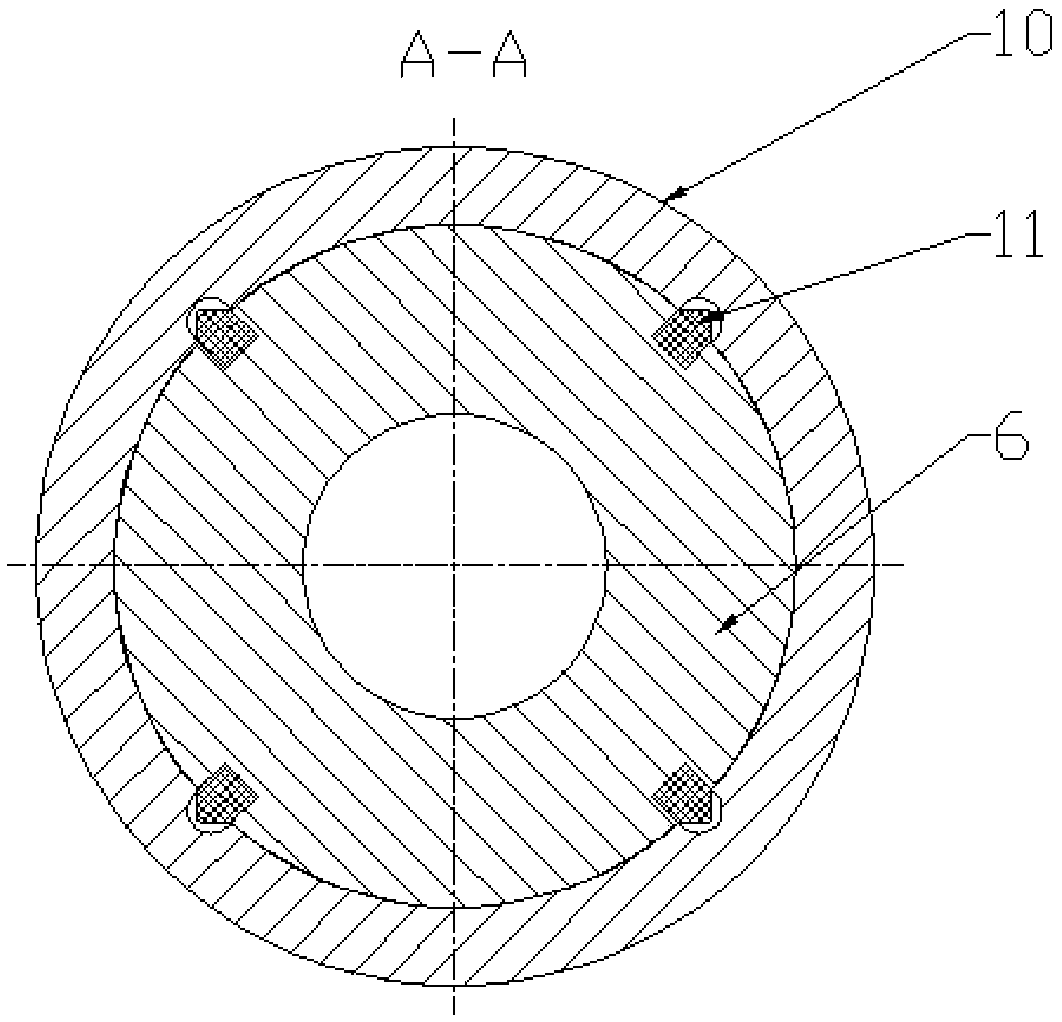

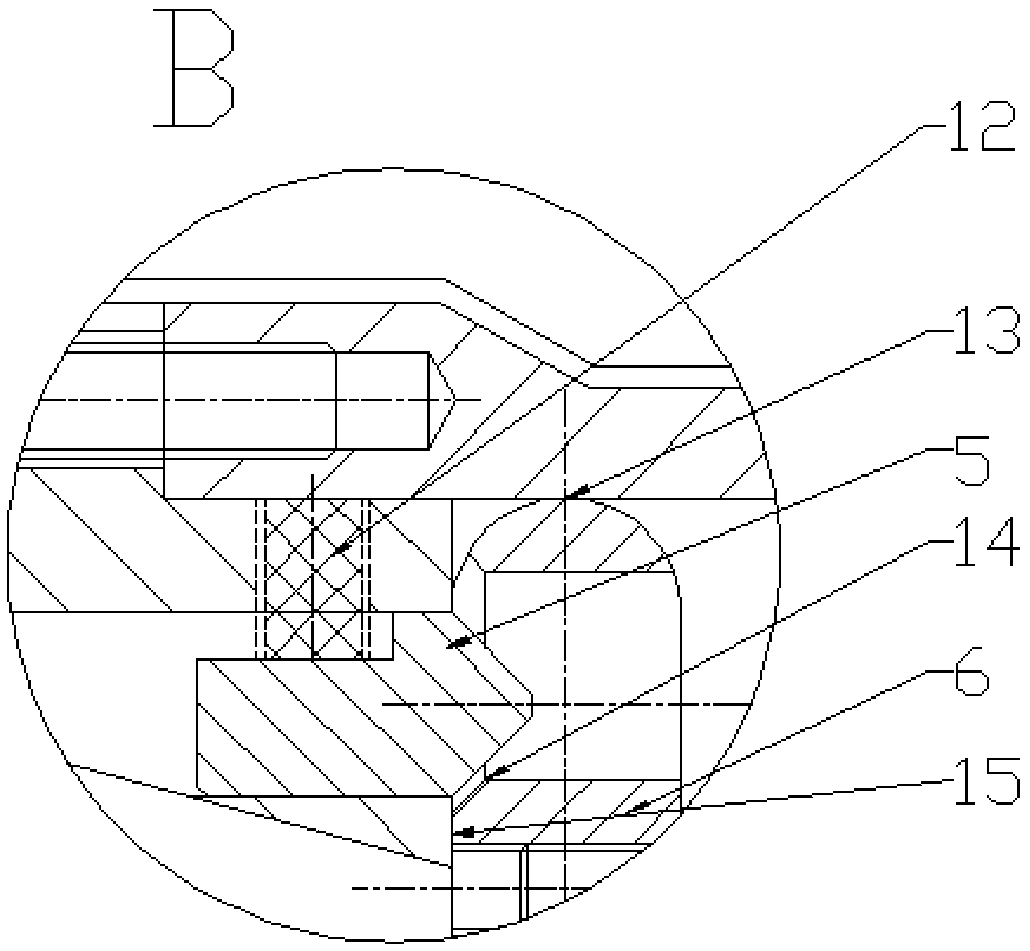

[0033] Such as Figure 1 ~ Figure 3 As shown, a robot welding and cutting anti-collision device includes a mandrel 3, a cover plate 4, a reset plate 6, an auxiliary spring 7, and a casing 10; wherein, the mandrel 3 is a hollow structure, and a welding torch is installed at one end. There is a U-shaped welding gun positioning keyway on the wall, and the other end is connected to the reset plate 6; the reset plate 6 is round cake-shaped, set on one end of the mandrel 3, and is fixedly connected with the mandrel 3; the shell 10 is divided into an open end and an open end. The bottom and the open end are equipped with a cover plate 4, and the center of the bottom has a circular through hole; the middle of the cover plate 4 has a circular through hole, which is used to pass the mandrel 3 and keep a certain distance without contact with the mandrel 3; The spring 7 is a pressure spring, and one end of the mandrel 3 with the reset plate 6 is pressed and connected with the inner bottom...

Embodiment 2

[0041] refer to Figure 1 ~ Figure 3 As shown, a robot welding and cutting anti-collision device includes a mandrel 3, a cover plate 4, a reset plate 6, an auxiliary spring 7, and a housing 10; wherein, the mandrel 3 is a hollow structure, and a welding torch is installed at one end. There is a U-shaped welding torch positioning keyway on the wall, and the other end is connected to the reset plate 6; the reset plate 6 is round cake-shaped, set on one end of the mandrel 3, and is fixedly connected with the mandrel 3; the shell 10 is divided into an open end and an open end. The bottom and the open end are equipped with a cover plate 4, and the center of the bottom has a circular through hole; the middle of the cover plate 4 has a circular through hole, which is used to pass the mandrel 3 and keep a certain distance without contact with the mandrel 3; The spring 7 is a pressure spring, and one end of the mandrel 3 with the reset plate 6 is pressed and connected with the inner bo...

Embodiment 3

[0046] An anti-collision device for robot welding and cutting, including a mandrel 3, a cover plate 4, a reset plate 6, an auxiliary spring 7, and a casing 10; the structures and functions of specific components are the same as those in Embodiment 1.

[0047] The robot welding and cutting anti-collision device provided by the present invention has the following working process: when the welding torch or cutting torch encounters an obstacle when working, the welding torch or cutting torch pushes the mandrel 3 to rotate, and the mandrel 3 is linked with the reset plate 6 to make the reset plate 6 A gap is generated between the cover plate 4 and any one of the 1-N sensors or microswitches 9 receives a signal, and the robot stops moving. During this collision process, after the reset plate 6 is disengaged from the cover plate 4, the suction force of the magnet 8 decreases, the force of the auxiliary spring 7 increases, and the resultant force of the pressure of the auxiliary spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com