Burr polisher for gear machining

A grinding machine and gear technology, which is used in metal processing equipment, grinding machine parts, machine tools suitable for grinding workpiece edges, etc., can solve problems such as the inability to achieve uniform grinding of gear teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

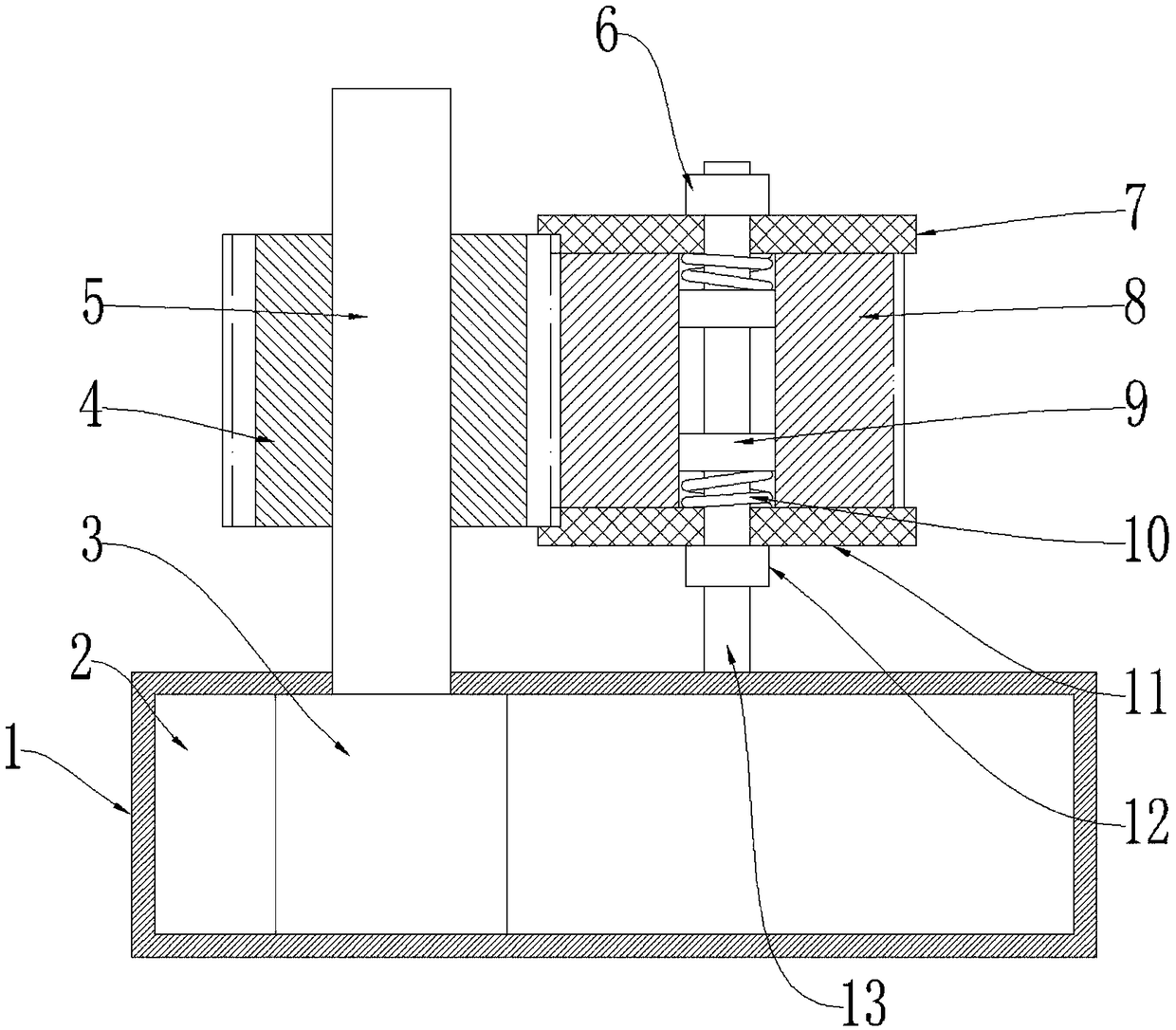

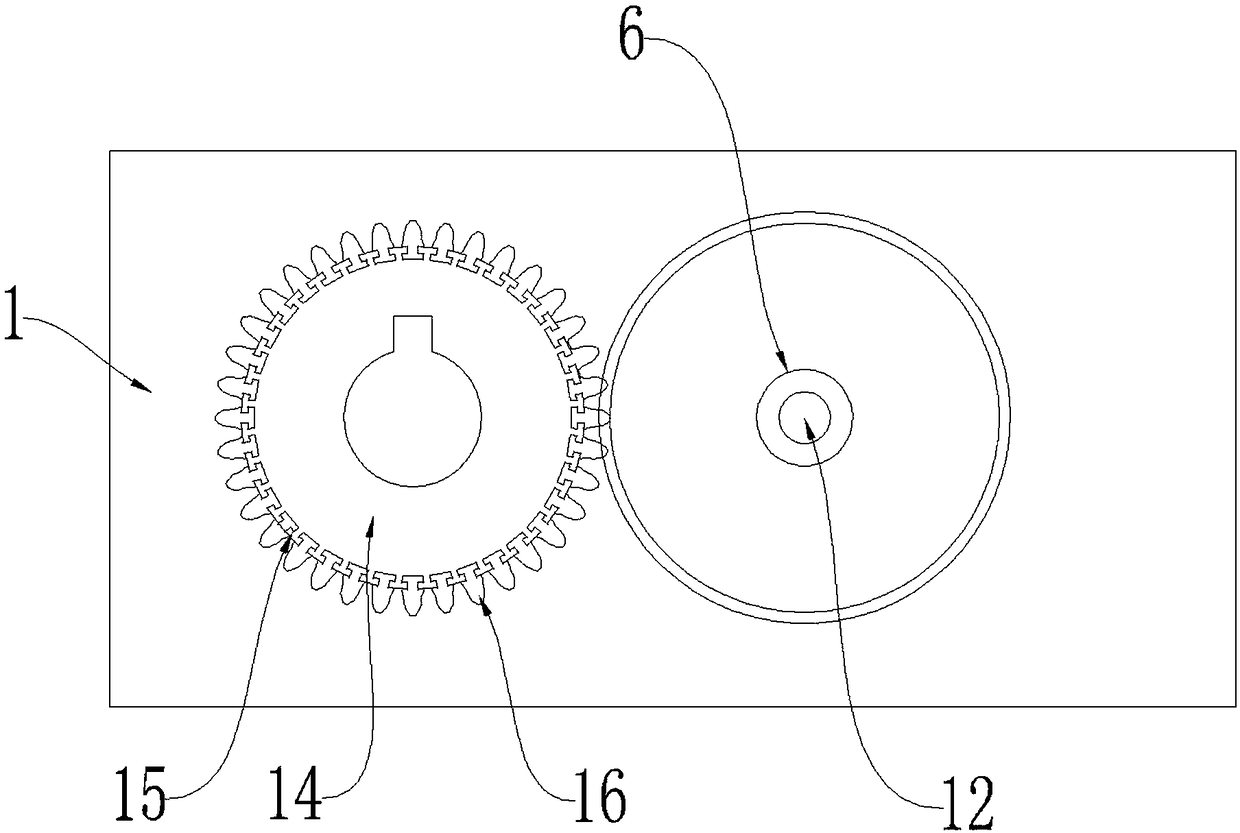

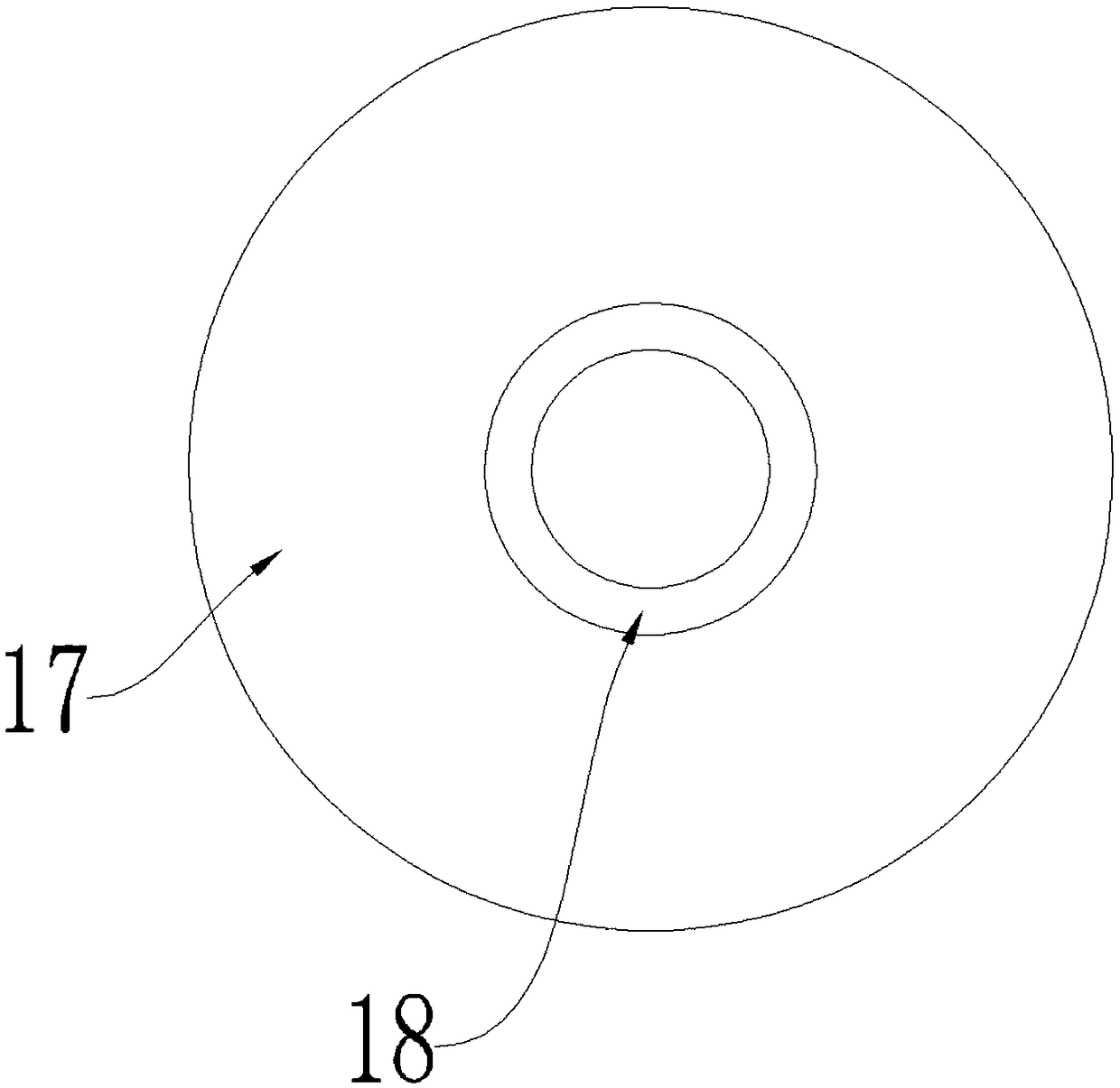

[0017] Such as figure 1 and figure 2 As shown, a burr grinder for gear processing includes a base 1, a drive chamber 2 is provided in the base 1, and a drive motor 3 is provided in the drive chamber 2. A brush shaft 5 is rotatably installed on the base 1, and the drive motor 3 drives the brush shaft 5 to rotate; a wheel brush 4 is fixed on the brush shaft 5, and the wheel brush 4 includes a brush hub 14. The outer wall of the hub 14 is evenly provided with several draw-in slots 15 extending axially along the brush hub 14, the draw-in slots 15 are provided with brush strips 16, and the brush strips 16 are tooth-shaped; the brush strips 16 and The brush hubs 14 jointly form a gear shape, and are in transmission contact with the gear to be deburred similar to gear meshing. It also includes a gear support shaft 13 fixed on the base 1, a lower friction disc 11 and an upper friction disc 7 are slidably arranged on the gear support shaft 13, and a supporting member is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com