Paper cup bowl and paper cup bowl curled edge molding mould

A forming mold and curling technology, which is applied to paper/cardboard containers, papermaking, rigid containers, etc., can solve the problems of affecting the shelf life of food in paper cups and bowls, unfavorable stable placement of paper cups and bowls, and entry of humid air, etc., to achieve stable placement, The effect of maintaining the beautiful appearance and improving the sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

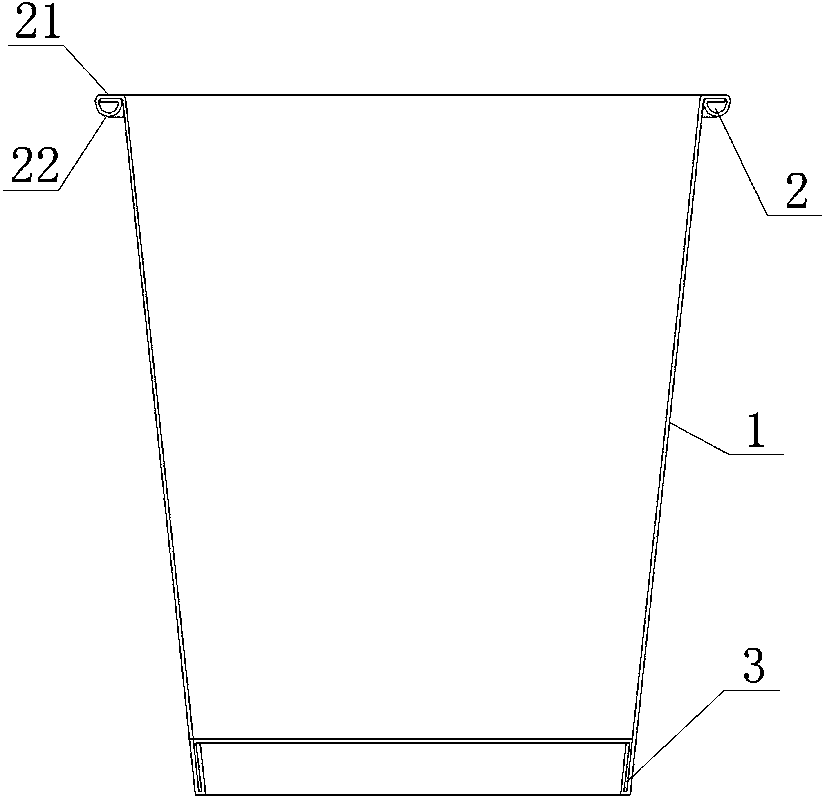

[0026] Such as figure 1 As shown, a paper cup and bowl includes a cup barrel 1, the mouth of the cup barrel 1 is provided with a curling 2, the bottom of the cup barrel 1 is provided with a cup bottom 3, and the curling edge 2 has a side line that is flat on the top and round on the bottom. The flat edge line 21 and the lower circular edge line 22 make the curling into an oblate structure.

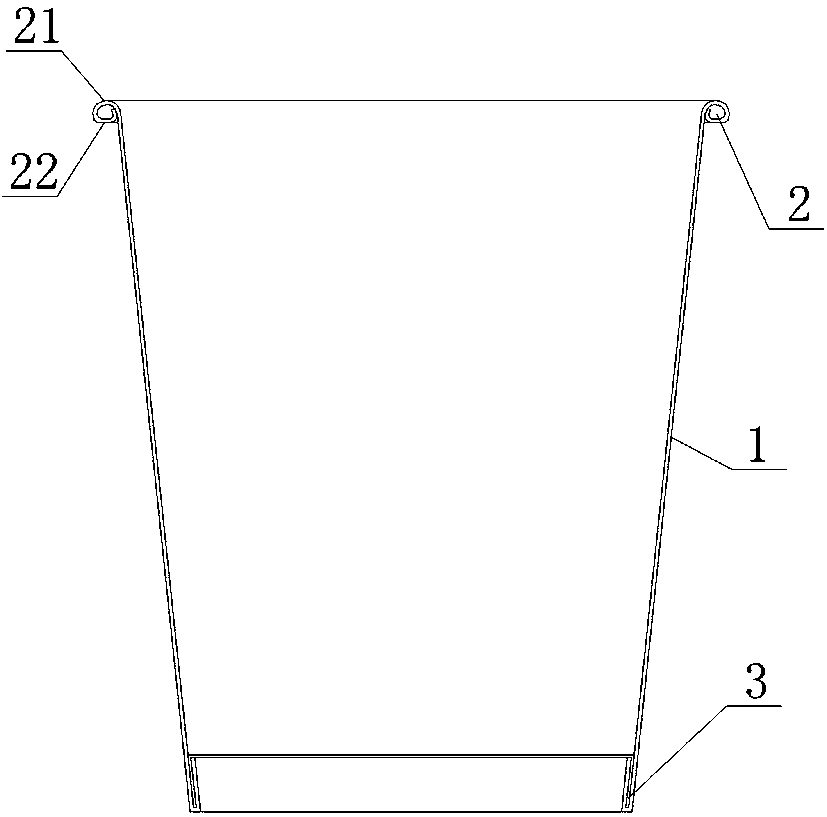

[0027] Such as figure 2 As shown, a paper cup and bowl includes a cup barrel. The mouth of the cup barrel is provided with a curling edge, and the bottom of the cup barrel is provided with a cup bottom. The curling edge has an upper circle and a lower flat edge line, so that the curling edge becomes oblate structure.

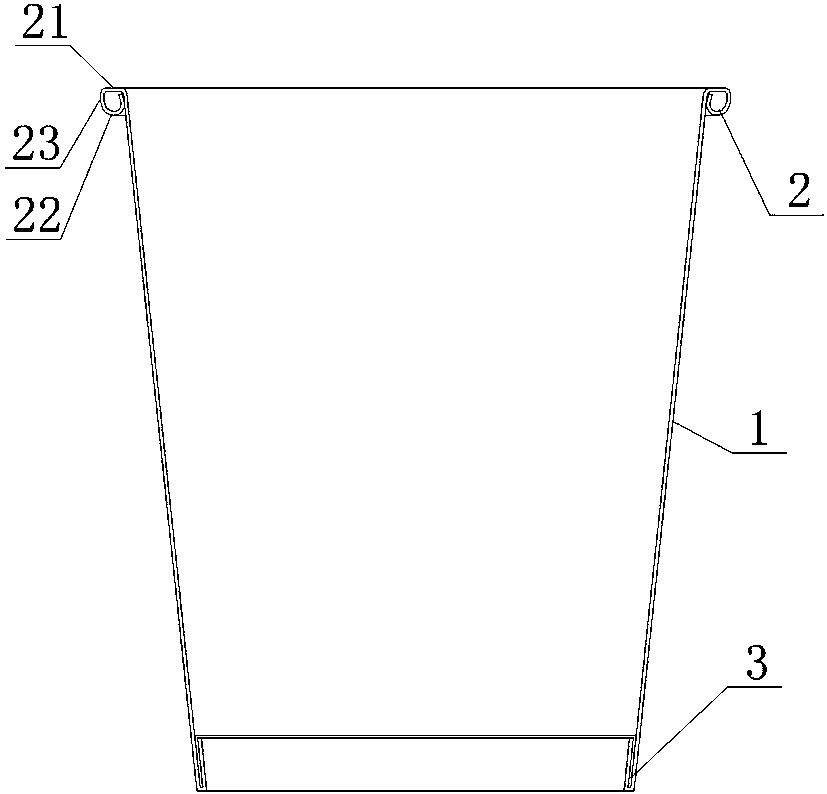

[0028] Such as image 3 As shown, a paper cup and bowl includes a cup barrel 1, the mouth of the cup barrel 1 is provided with a curling 2, the bottom of the cup barrel 1 is provided with a cup bottom 3, and the curling edge 2 has a side line that is flat on the top and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com