Preparation method of ceramic tile with discontinuous sag texture with controllable depth

A continuous, ceramic tile technology, applied in the field of architectural ceramics, can solve the problems of discontinuity, patchwork, and difficult to achieve subsidence effects, and achieve the effects of solving pollution, controlling depth, and realizing discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The green body is formed, the surface glaze is applied, and the ceramic ink imitating the natural marble pattern is printed.

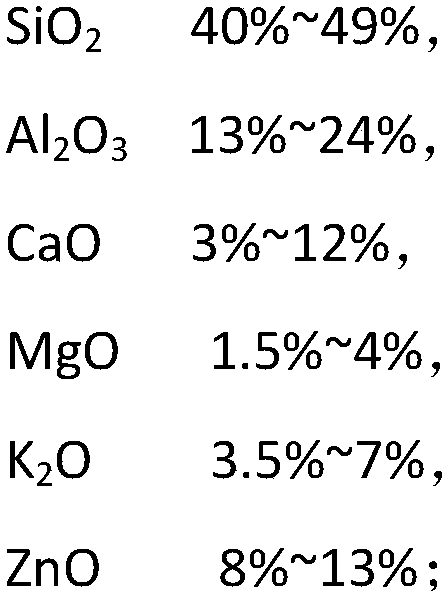

[0026] (2) Spray a layer of 0.2mm transparent protective glaze on the surface of the ceramic ink pattern. The composition of the protective glaze is:

[0027]

[0028] (3) According to the effect picture of the off-line texture of natural marble, spray 25g of vinyl acetate glue on the area of the inkjet pattern surface that does not need to achieve the sinking effect. The thermal decomposition temperature of the glue is 300°C.

[0029] (4) Get 500g frit dry grain and evenly distribute on pattern surface, the gradation of described frit dry grain is:

[0030] 50-100 mesh 10%,

[0031] 100-200 mesh 50%,

[0032] 200-500 mesh 40%;

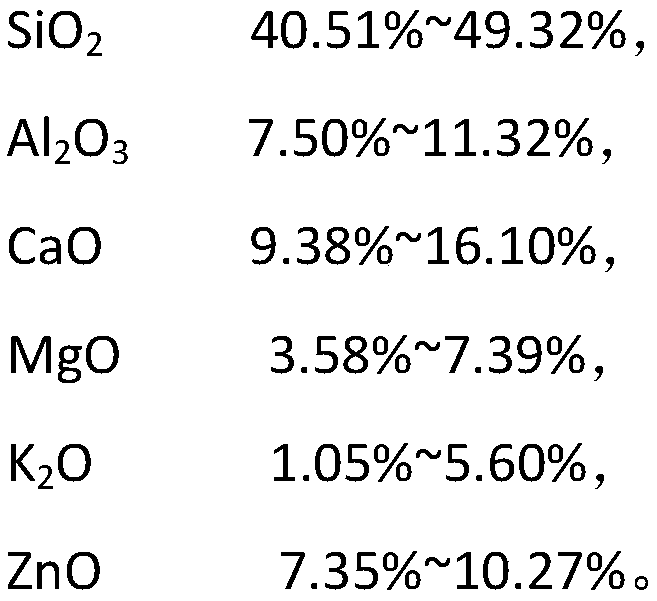

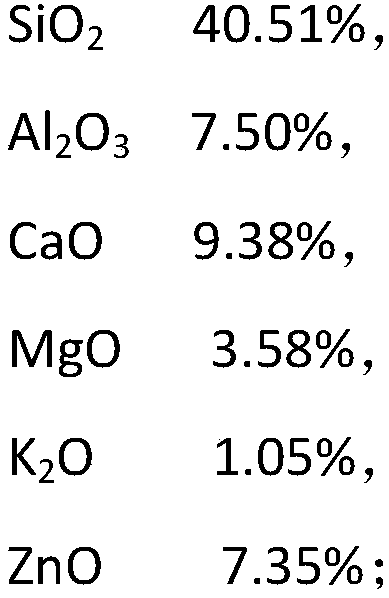

[0033] The composition of the frit is:

[0034]

[0035] After curing at 80°C, the frit dry particles are adsorbed on the glue;

[0036] (5) Control the rotating speed of the blower fan to 200r / min, swe...

Embodiment 2

[0038] (1) The green body is formed, the surface glaze is applied, and the ceramic ink imitating the natural marble pattern is printed.

[0039] (2) Spray a layer of 1mm transparent protective glaze on the surface of the ceramic ink pattern. The composition of the protective glaze is:

[0040]

[0041] (3) According to the effect picture of the natural marble off-line texture, spray 50g of glue on the area of the inkjet pattern surface that does not need to achieve the sinking effect. The thermal decomposition temperature of the glue is 700°C.

[0042] (4) get frit dry grain 500g and evenly distribute on pattern surface, the gradation of described frit dry grain is:

[0043] 50-100 mesh 25%,

[0044] 100-200 mesh 50%,

[0045] 200-500 mesh 25%;

[0046] The composition of frit dry granule is:

[0047]

[0048] After curing at 150°C, the frit dry particles are adsorbed on the glue.

[0049] (5) Control the rotating speed of the blower fan to 200r / min, sweep away th...

Embodiment 3

[0051] (1) The green body is formed, the surface glaze is applied, and the ceramic ink imitating the natural marble pattern is printed.

[0052] (2) Spray a layer of 1mm transparent protective glaze on the surface of the ceramic ink pattern. The composition of the protective glaze is:

[0053]

[0054] (3) According to the effect picture of the natural marble off-line texture, spray 40g of α-ethyl cyanoacrylate glue on the area of the inkjet pattern surface that does not need to achieve the sinking effect. The thermal decomposition temperature of the glue is 500°C;

[0055] (4) get frit dry grain 800g and evenly distribute on pattern surface, the gradation of described frit dry grain is:

[0056] 50-100 mesh 15%,

[0057] 100-200 mesh 45%,

[0058] 200-500 mesh 40%;

[0059] The composition of frit dry granule is:

[0060]

[0061] After curing at 100°C, the frit dry particles are adsorbed on the glue.

[0062] (5) Control the rotating speed of the blower fan to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com